Nano carbon black with metallic luster and preparation method thereof

A technology of nano-carbon black and metallic luster, which is applied in chemical instruments and methods, household utensils, dyed organosilicon compounds, etc., can solve the problems of large specific surface area, slow curing, and low production efficiency of nano-carbon black, and improve storage efficiency. Enhanced stability, dispersion performance, and improved productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

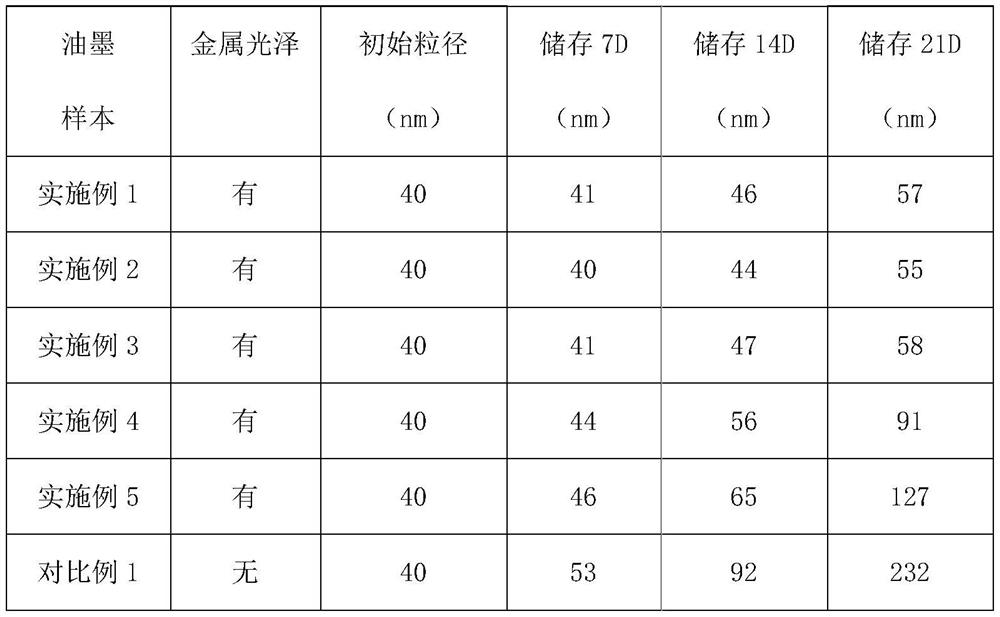

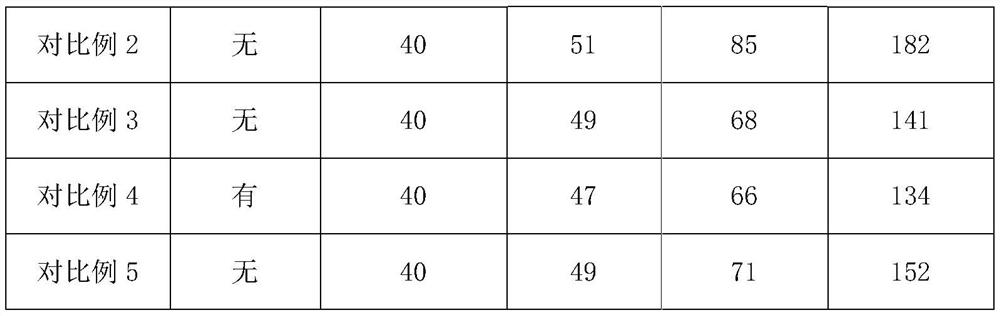

Examples

Embodiment 1

[0026] A kind of nano carbon black with metallic luster, the preparation method of described nano carbon black is:

[0027] (1) Nano carbon black is dispersed in the THF of its mass multiple 3 times, and stir;

[0028] (2) add the tributyl vinyl tin of nano carbon black quality 0.5%, disperse evenly;

[0029] (3) distillation under reduced pressure obtains the nano carbon black that is adsorbed with tributyl vinyl tin, and reclaims THF;

[0030] (4) the nano-carbon black that the adsorption that step (3) obtains has tributylvinyl tin adds fluidized-bed reactor, feeds ozone: the mixed gas that air volume ratio is 1:100, reaction 2h, total ventilation 2m per kilogram of nano carbon black 3 ;

[0031] (5) After the reaction is completed, continue to add the silicone oil toluene solution with a volume fraction of 0.3 times the mass of nano carbon black in a spraying manner, and after the dispersion is uniform, spray dry under reduced pressure and recycle toluene, and the obtain...

Embodiment 2

[0038] A kind of nano carbon black with metallic luster, the preparation method of described nano carbon black is:

[0039] (1) Nano carbon black is dispersed in the THF of its mass multiple 4 times, and stir;

[0040] (2) add the tributyl vinyl tin of nano carbon black quality 0.8%, disperse evenly;

[0041] (3) distillation under reduced pressure obtains the nano carbon black that is adsorbed with tributyl vinyl tin, and reclaims THF;

[0042] (4) Add the nano-carbon black of tributylvinyltin to the adsorption obtained in the step (3) into the fluidized bed reactor, feed ozone: the air volume ratio is a mixed gas of 2:100, react for 1.5h, and ventilate The amount is 1.8m per kilogram of nano carbon black 3 ;

[0043] (5) After the reaction is completed, continue to add the silicone oil toluene solution with a volume fraction of 0.4 times the mass of nano carbon black and 1.2% in a spraying manner. After the dispersion is uniform, spray dry under reduced pressure and recyc...

Embodiment 3

[0050] A kind of nano carbon black with metallic luster, the preparation method of described nano carbon black is:

[0051] (1) Nano carbon black is dispersed in the THF of its mass multiple 5 times, and stir;

[0052] (2) add the tributyl vinyl tin of nano carbon black quality 1.0%, disperse evenly;

[0053] (3) distillation under reduced pressure obtains the nano carbon black that is adsorbed with tributyl vinyl tin, and reclaims THF;

[0054] (4) the nano-carbon black that the adsorption that step (3) obtains has tributylvinyl tin adds fluidized-bed reactor, feeds ozone: the mixed gas that air volume ratio is 3:100, reaction 1h, total ventilation 1m per kilogram of nano carbon black 3 ;

[0055] (5) After the reaction is completed, continue to add 0.5 times the volume fraction of nano-carbon black in a spraying manner and be 2% silicone oil toluene solution. After the dispersion is uniform, spray dry under reduced pressure and recycle toluene. carbon black;

[0056] (6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com