Method for separating and analyzing impurities in NF3

A technology for separating analysis and impurities, which is applied in the field of analytical chemistry, can solve the problems of destroying and protecting the detector, and achieve the effects of protecting the detector, short analysis time and remarkable separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

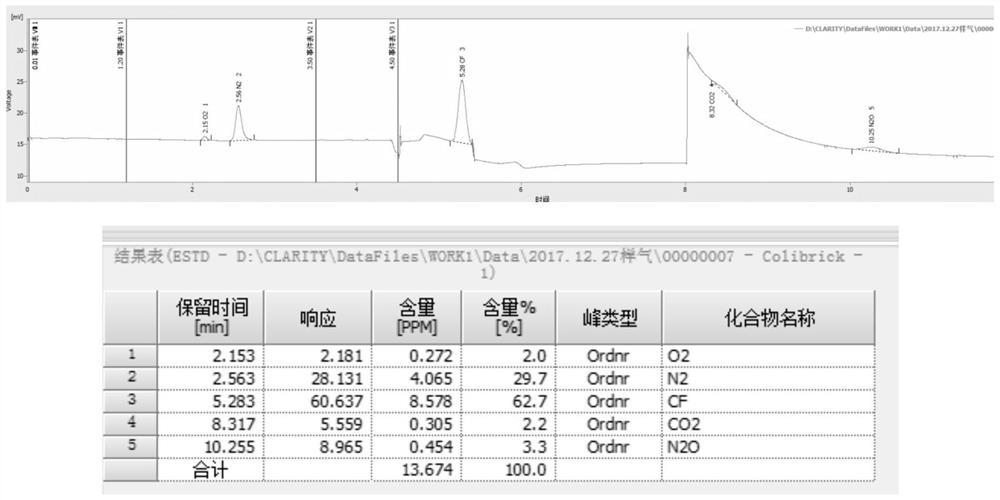

Embodiment 1

[0034] NF 3 Separation and analysis method of impurities in medium:

[0035] Column temperature: 70 degrees

[0036] Detector temperature: 40 degrees

[0037] Column flow: 25ml / min

[0038] Type of carrier gas: through Ultra-high purity helium after purifier

[0039] Injection volume: 1ml

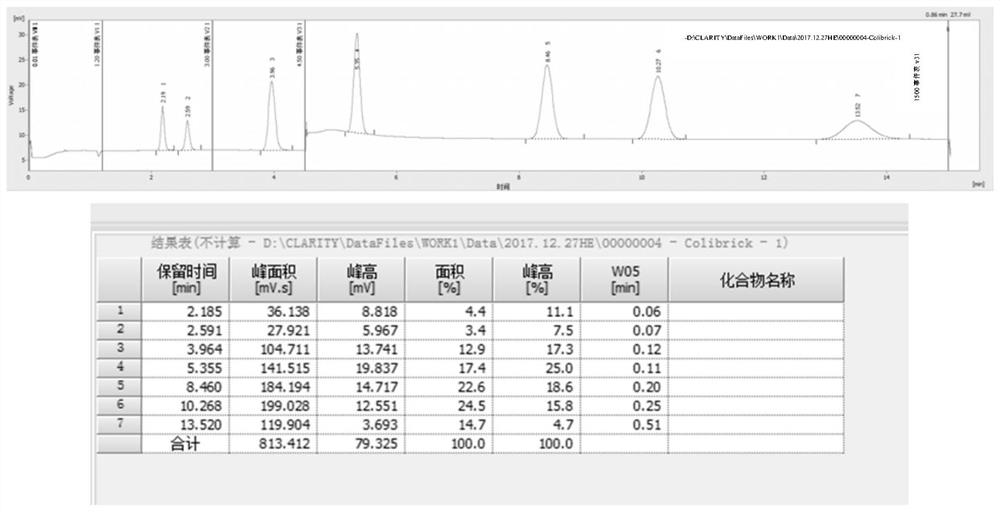

[0040] Analytical instruments use Gaomai's 592 / 816 series instruments to separate O 2 +Ar,N 2 , CO is separated by 6 feet 1 / 8 SC-ST+8 feet 1 / 8 13X molecular sieve, which can effectively separate NF 3 Pull away from the previously analyzed impurities, and then choose the appropriate time to backflush or cut, the NF 3 Drain from pre-column. Analyze CF 4 , CO 2 , N 2 O. SF 6 15 feet 1 / 8 haysep N and 20 feet 1 / 8 haysep N are used. Choosing this column can maximize CF 4 with NF 3 for separation, the CF 4 At the moment when the peak and tail of the peak fall, switch the column selection valve and set the NF 3 Drain, column 1 into the detector, to prevent a large amount of NF 3 ...

Embodiment 2

[0044] The method according to claim 1, characterized in that, determine the oxidizability of NF3 by the following method to investigate its damage to the detector:

[0045] S1, pass NF3 into the container containing reducing agent solution protected by inert gas;

[0046] S2, control the temperature in the container to be 25, 30, 35, 40, 45, 50, 55, 60°C respectively; keep it for a period of time, flush 2-3 times the volume of the container with inert gas to drive away NF3, and investigate the reducing agent solution Oxidation;

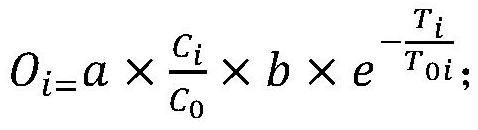

[0047] S3, estimate the oxidation coefficient of NF3 by the following formula:

[0048]

[0049] Wherein, a and b are constants, Ci is the amount of feeding NF3, and Ti is the temperature;

[0050]S4, take the oxidized condition of the reducing agent solution measured in S3 to calculate the constant in the formula of S5; group the obtained constants from high to low, the difference within the group is not significant, and the difference between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com