Flue gas denitration catalyst and preparation method thereof

A denitrification catalyst and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of large recycling loss, complex process flow, and large consumption, and achieve low cost of load , wide source of raw materials and high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

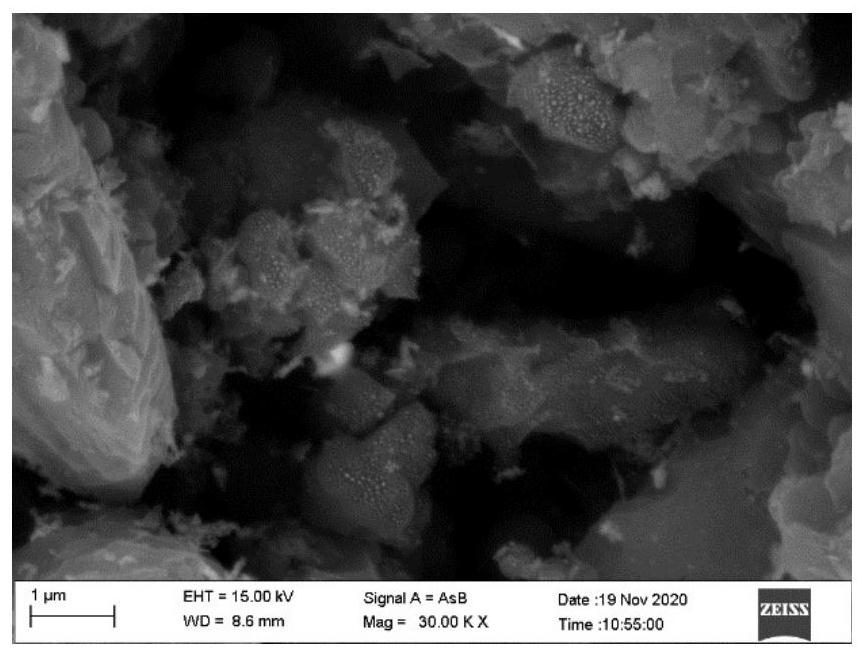

Image

Examples

Embodiment 1

[0042] Example 1, preparation of high-efficiency low-temperature catalyst samples

[0043] The commercial activated carbon was placed in a 20% nitric acid aqueous solution, stirred for 1 h, left standing for 12 h, taken out and dried, calcined at 400 °C for 0.5 h in a microwave tube furnace, and then immersed in a 4% copper nitrate solution by mass fraction. , where the volume of the solution is the volume of water absorption of the activated carbon at this time, dried, placed in a common tube furnace after drying, raised to 400°C at a rate of 10°C / min under a nitrogen atmosphere, kept at a constant temperature for 1h, and cooled naturally to room temperature. The obtained sample was immersed again in a 4% cerium nitrate solution, wherein the volume of the solution was the volume of water absorption of the activated carbon at this time, dried, and then placed in an ordinary tube furnace under nitrogen atmosphere at 10 ° C. The rate of / min was raised to 400°C, kept at a const...

Embodiment 2

[0047] Other conditions are the same as in Example 1, the difference is that the carrier is immersed in a 4% copper nitrate solution, wherein the volume of the solution is the volume of water absorption of the activated carbon at this time, and drying is carried out for 2 times in turn, and the total amount is 8 %, while cerium nitrate is also immersed twice, other conditions and test conditions are the same as 1. The catalyst had a breakthrough time of 258 min, which was stronger than Example 1.

Embodiment 3

[0049] Other conditions are the same as in Example 1, the difference is that the carrier is immersed in a 4% copper nitrate solution by mass, wherein the volume of the solution is the volume of water absorption of the activated carbon at this time, and drying is carried out 3 times in turn, and the total amount is 12 %, and cerium nitrate was also immersed for 3 times, and other conditions and test conditions were the same as 1. The catalyst had a breakthrough time of 366 min, which was stronger than Example 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com