Method and device for preparing sodium bicarbonate by electrochemically capturing carbon dioxide

A technology of carbon dioxide and sodium bicarbonate, applied in the field of flue gas purification, can solve the problems of difficult control of the quality of the decarbonization by-product calcium carbonate, environmental risks, etc., and achieve the effects of fast reaction rate, high removal efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for electrochemically capturing carbon dioxide to prepare sodium bicarbonate, the specific operations are as follows:

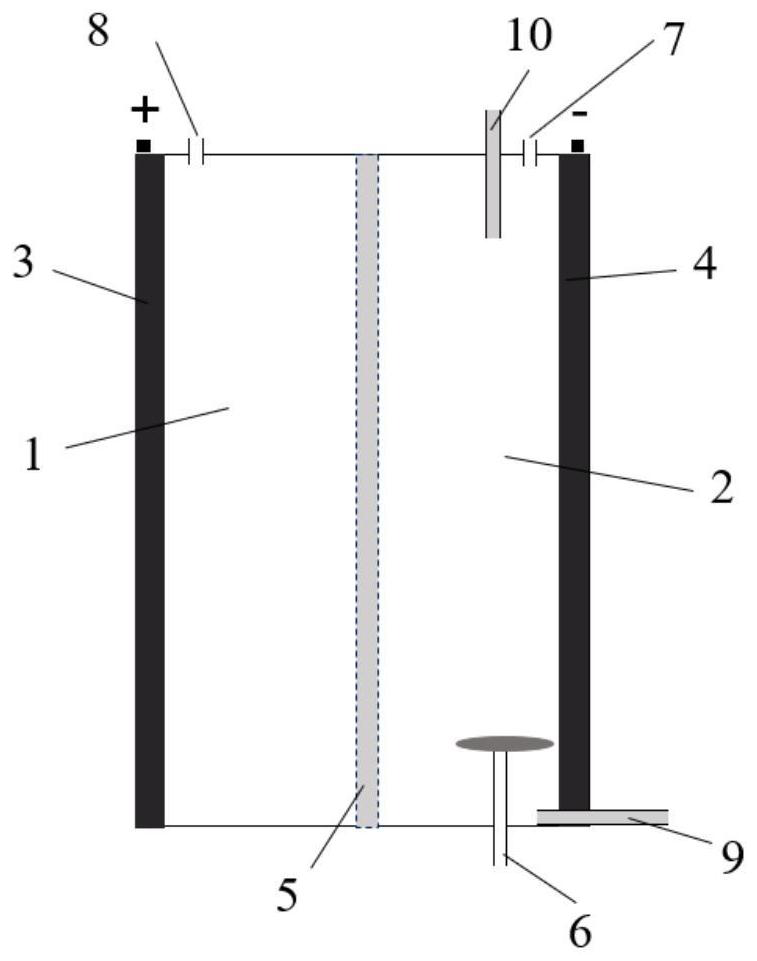

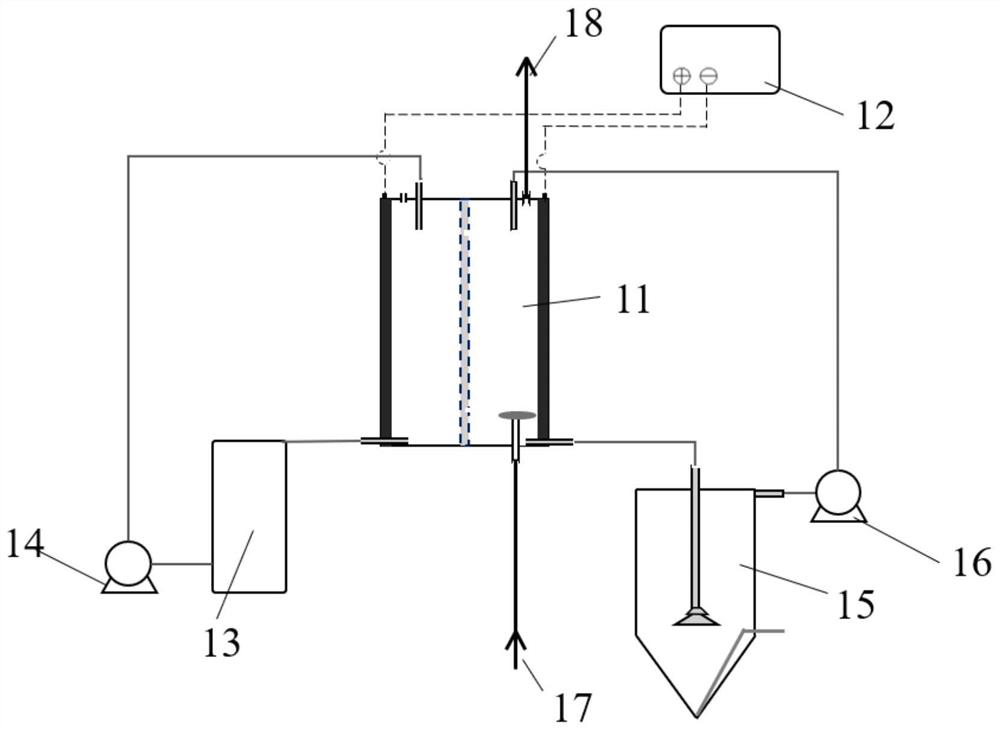

[0033] (1) At room temperature, the reaction chamber is divided into cathode chamber 2 and anode chamber 1 by cation exchange membrane 5, wherein the anode injects the desulfurization by-product (NaHSO of about 0.1mol / L 4 ), the cathode chamber 2 is injected with a NaOH solution of 0.5mol / L concentration, and under the action of the electric field drive and the cation exchange membrane 5, the cation Na + Selectively enter the cathode chamber 2, and the OH produced by the electrolysis of water in the cathode chamber 2 - Combined to generate NaOH, the H produced by the electrolysis of water in the anode chamber 1 + Combine with anion to form H 2 SO 4 .

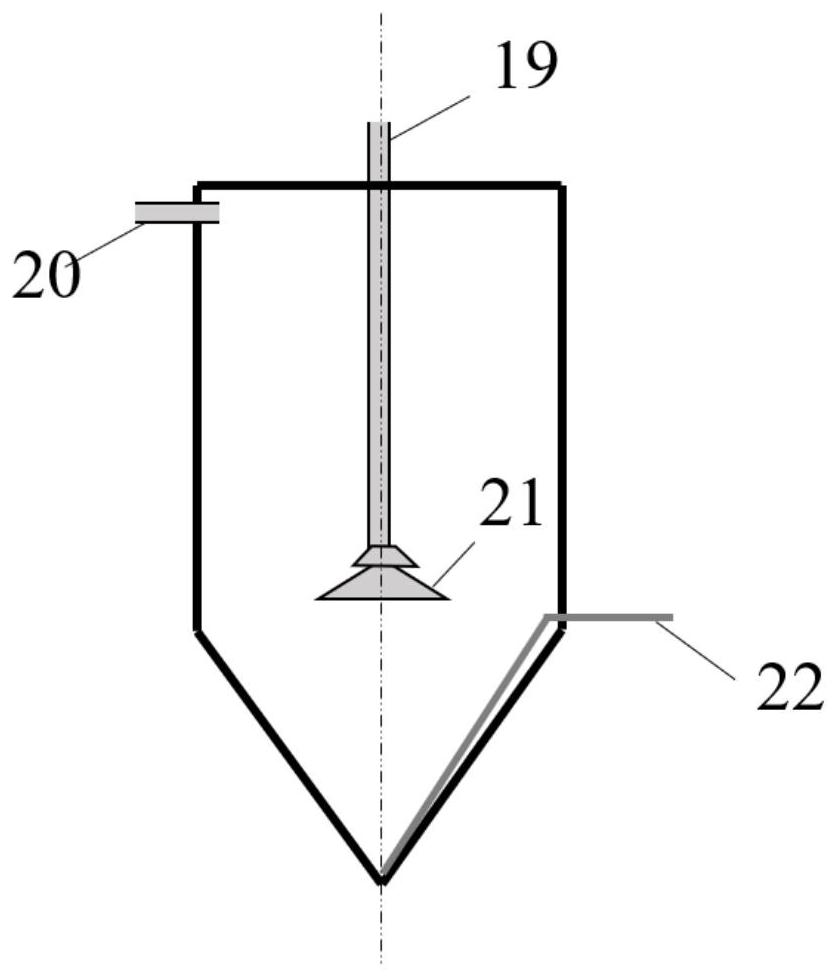

[0034] (2) At the same time, the gas containing 10% carbon dioxide after dedusting, desulfurization and denitrification is introduced from the gas inlet 17 at the bottom of the cathode chamb...

Embodiment 2

[0038] A method for electrochemically capturing carbon dioxide to prepare sodium bicarbonate, the specific operations are as follows:

[0039] (1) At room temperature, the reaction chamber is divided into cathode chamber 2 and anode chamber 1 by cation exchange membrane 5, wherein the anode injects the desulfurization by-product (about 0.5mol / L Na 2 SO 3 ), the cathode chamber 2 is injected with a NaOH solution with a concentration of 0.5mol / L, and 1A / m is applied between the anode and the cathode 2 DC constant current, electrode materials are graphite plates. Driven by the electric field and under the action of the cation exchange membrane 5, the cation Na + Selectively enter the cathode chamber 2, and the OH produced by the electrolysis of water in the cathode chamber 2 - combined to form NaOH, SO in the anode compartment 1 3 2- is oxidized to SO 3 2- , and the H produced by electrolysis of water + Combine with anion to form H 2 SO 4 .

[0040] (2) At the same tim...

Embodiment 3

[0044] A method for electrochemically capturing carbon dioxide to prepare sodium bicarbonate, the specific operations are as follows:

[0045] (1) At room temperature, the reaction chamber is divided into cathode chamber 2 and anode chamber 1 by cation exchange membrane 5, wherein the anode injects the desulfurization by-product (0.1mol / L Na 2 SO 4 ), the cathode chamber 2 is injected with a NaOH solution with a concentration of 0.5mol / L, and 1A / m is applied between the anode and the cathode 2 DC constant current, electrode materials are graphite plates. Driven by the electric field and under the action of the cation exchange membrane 5, the cation Na + Selectively enter the cathode chamber 2, and the OH produced by the electrolysis of water in the cathode chamber 2 - Combined to generate NaOH, the H produced by the electrolysis of water in the anode chamber 1 + Combine with anion to form H 2 SO 4 .

[0046] (2) At the same time, the gas containing 20% carbon dioxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com