Degradable efficient gypsum retarder as well as preparation method and application thereof

A gypsum retarder and retarder technology, which can be used in climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of poor phosphogypsum retarder effect and gypsum retarder not being green and environmentally friendly. , to achieve good retardation effect and excellent application performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

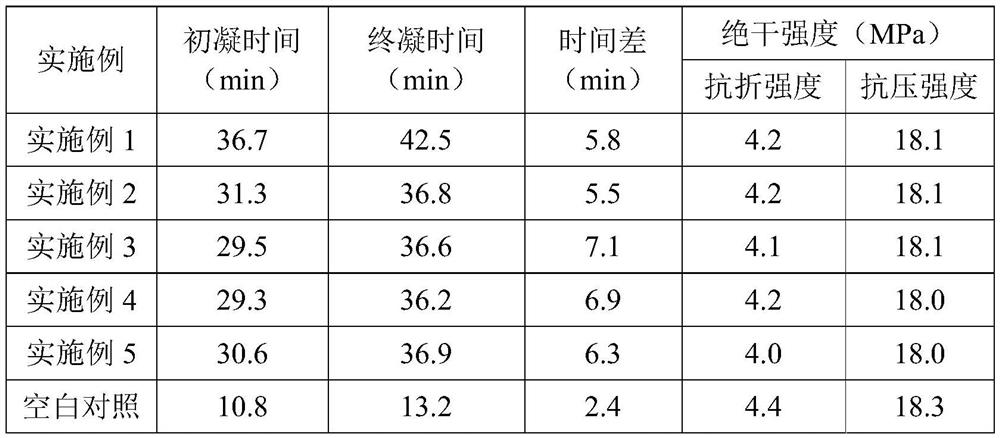

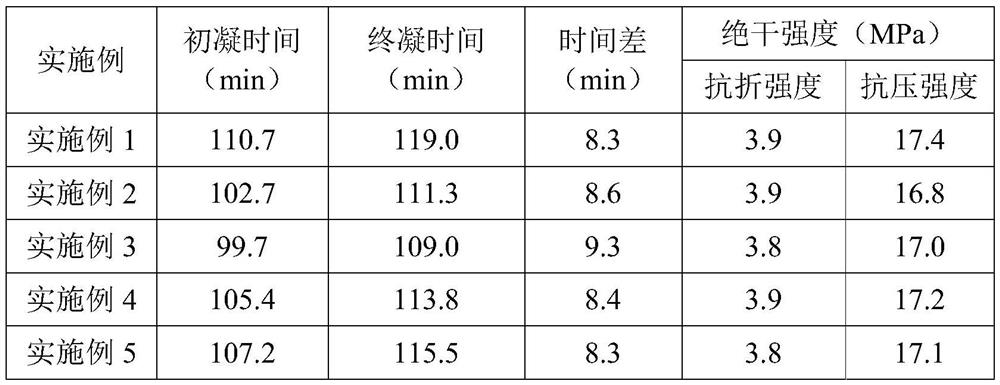

Examples

Embodiment 1

[0020] This example provides a degradable high-efficiency gypsum retarder, which is compounded by calcium polyaspartate and tetrasodium iminodisuccinate with a mass ratio of 25:1.5. Its preparation method is:

[0021] Calcium polyaspartate is made into the calcium polyaspartate aqueous solution of 40% by mass fraction, and the massfraction of tetrasodium iminodisuccinate in the tetrasodium iminodisuccinate aqueous solution is 33%, and the obtained polyaspartate The aqueous solution of calcium partate and the aqueous solution of tetrasodium iminodisuccinate are mixed evenly at 35-45°C according to the mass ratio of 100:7.27, and then spray-dried with a spray drying tower, and the temperature inside the tower is controlled at 110-130°C. Pass the dried product through a 60-mesh sieve.

Embodiment 2

[0023] This example provides a degradable high-efficiency gypsum retarder, which is compounded by calcium polyaspartate and tetrasodium iminodisuccinate with a mass ratio of 25:1. Its preparation method is:

[0024] Calcium polyaspartate is made into the calcium polyaspartate aqueous solution of 40% by mass fraction, and the massfraction of tetrasodium iminodisuccinate in the tetrasodium iminodisuccinate aqueous solution is 33%, and the obtained polyaspartate The aqueous solution of calcium aspartate and the aqueous solution of tetrasodium iminodisuccinate are mixed evenly at 35-45°C at a mass ratio of 100:4.85, and then spray-dried with a spray drying tower, and the temperature inside the tower is controlled at 110-130°C. Pass the dried product through a 60-mesh sieve.

Embodiment 3

[0026] This example provides a degradable high-efficiency gypsum retarder, which is compounded by calcium polyaspartate and tetrasodium iminodisuccinate with a mass ratio of 25:2. Its preparation method is:

[0027] Calcium polyaspartate is made into the calcium polyaspartate aqueous solution of 40% by mass fraction, and the massfraction of tetrasodium iminodisuccinate in the tetrasodium iminodisuccinate aqueous solution is 33%, and the obtained polyaspartate The aqueous solution of calcium aspartate and the aqueous solution of tetrasodium iminodisuccinate are mixed evenly at 35-45°C according to the mass ratio of 100:9.70, and then spray-dried by a spray drying tower, and the temperature inside the tower is controlled at 110-130°C. Pass the dried product through a 60-mesh sieve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com