Preparation method of fused silica powder for high-frequency high-speed copper-clad plate

A technology for silicon micropowder and copper clad laminate, which is applied in the field of preparation of molten silicon micropowder for high frequency and high speed copper clad laminates, can solve problems such as complicated processes, and achieve the effects of simple process, not easy to absorb water, and good compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

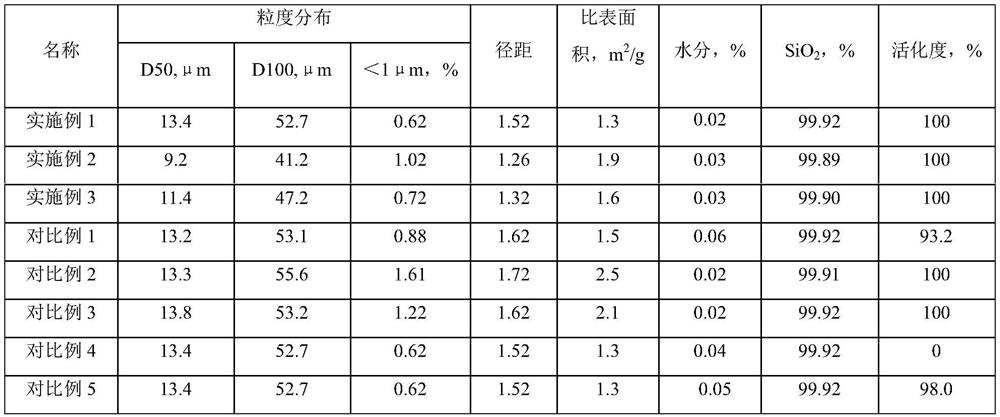

Embodiment 1

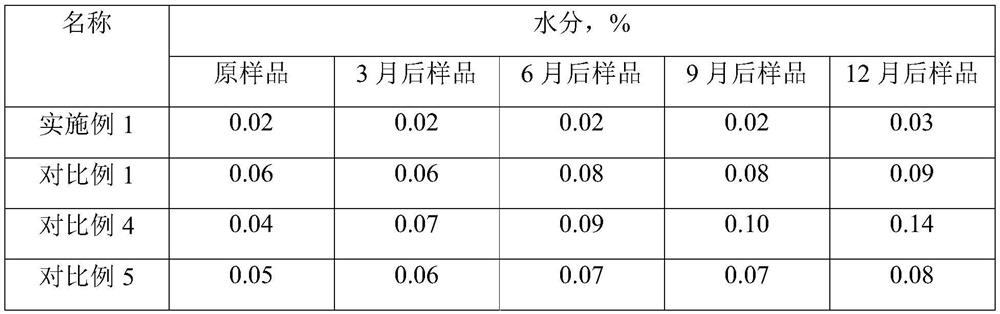

[0030] In step (1), the raw material of high-purity molten silicon micropowder with a particle size of D50=110.2 μm, diameter distance=1.31, magnetic substance=2.0 ppm, and silicon dioxide content of 99.93% is added to a jet mill for crushing, and the molten silicon is obtained by classification Micro powder semi-finished product, wherein the crushing pressure is 0.4MPa, the air flow temperature is 120°C, the particle size obtained by classification is D50=13.4μm, D100=52.7μm, 2 / g, a semi-finished product of fused silica powder with a silicon dioxide content of 99.92% and a moisture content of 0.08%;

[0031] In step (2), the semi-finished product of molten silicon powder is added to the modification machine, and the fluorine-containing silane KBM7103 (Shin-Etsu Chemical Industry Co., Ltd. of Japan) is added at the same time, and the modification is carried out at a temperature of 220 ° C. The modification time is 1.0 h, and then The fused silicon micropowder product for high-...

Embodiment 2

[0033] In step (1), the particle size is D50=38.2μm, the diameter distance=1.40, the magnetic substance=2.6ppm, and the high-purity fused silica sand of the high-purity fused silica micropowder raw material with a silicon dioxide content of 99.91% is added in the jet mill to carry out Crushing and grading to obtain a semi-finished product of fused silica powder, wherein the crushing pressure is 0.6MPa, and the airflow temperature is 160°C. The particle size of the semi-finished fused silica powder is D50=9.2μm, D100=41.2μm, 2 / g, silicon dioxide content is 99.89%, moisture content is 0.07%;

[0034] In step (2), add the semi-finished product of fused silica powder into the modification machine, and at the same time add heptadecafluorodecyltrimethoxysilane (Hangzhou Jessica Chemical Co., Ltd.), and modify it at a temperature of 240°C. The time is 1.0h, and then graded to obtain a fused silica powder product for high-frequency copper clad laminates, wherein the fused silica powd...

Embodiment 3

[0036] In step (1), the raw material of high-purity molten silicon micropowder with a particle size of D50=55.3 μm, radial distance=1.35, magnetic substance=2.2 ppm, and a silicon dioxide content of 99.91% is added to a jet mill for crushing, and the molten silicon is obtained by classification Micro-powder semi-finished product, in which the crushing pressure is 0.5MPa, the air flow temperature is 160°C, the particle size of the fused silica micro-powder semi-finished product is D50=11.4μm, D100=47.2μm, 2 / g, silicon dioxide content is 99.90%, moisture content is 0.06%;

[0037] In step (2), the semi-finished product of fused silica powder is added to the modification machine, and tridecafluorooctyltrimethoxysilane (Hangzhou Jessica Chemical Co., Ltd.) is added at the same time to modify at a temperature of 220 ° C. The modification time 1.0h, and then graded to obtain fused silica powder products for high-frequency copper-clad laminates, wherein the moisture content of the fu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com