Thermal stability evaluation method of lithium ion battery electrode material

A lithium-ion battery and electrode material technology, which is applied in the field of thermal stability evaluation of lithium-ion battery electrode materials, can solve the problems of lithium-ion battery fire, explosion, combustion, battery fire, etc., and achieves the effect of reducing the risk of thermal runaway

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] S1. Set the preset temperature T=260°C;

[0025] S2. Under an inert atmosphere, disassemble the LFP battery cell under 100% SOC state to obtain the negative pole piece, then soak the negative pole piece in DMC for 30 minutes to remove the electrolyte, after drying, scrape powder and grind it to obtain Anode material powder;

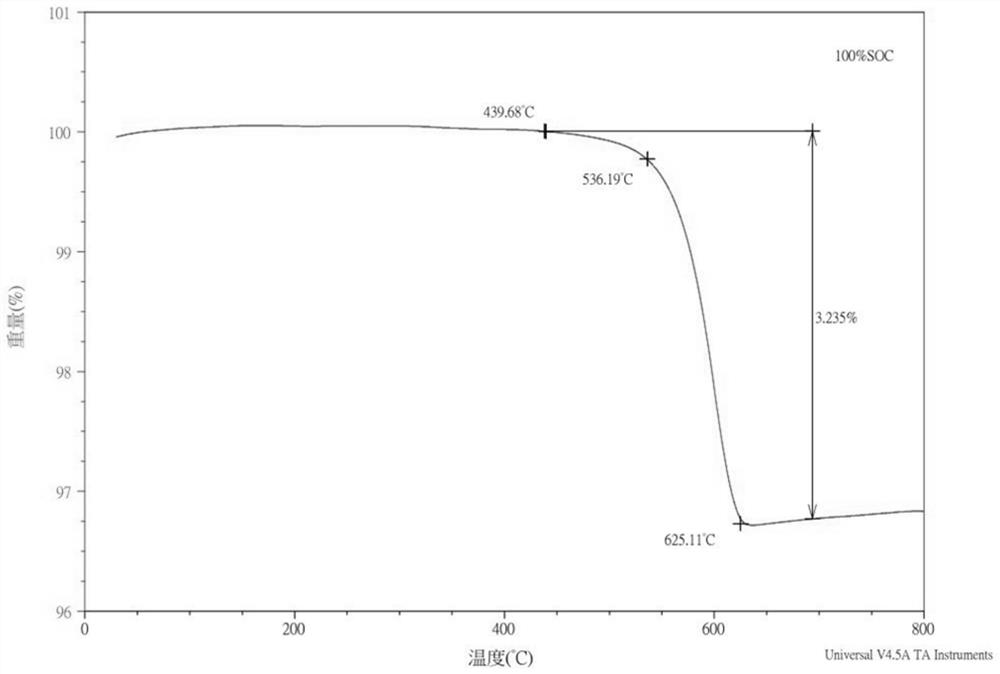

[0026] S3. Under an inert atmosphere, put the negative electrode material powder into an alumina crucible, and conduct a TG test at a heating rate of 10k / min. The termination temperature of the test is 800°C, and obtain the exothermic temperature T of the reaction between the negative electrode material and the electrolyte. 1 =439.68°C;

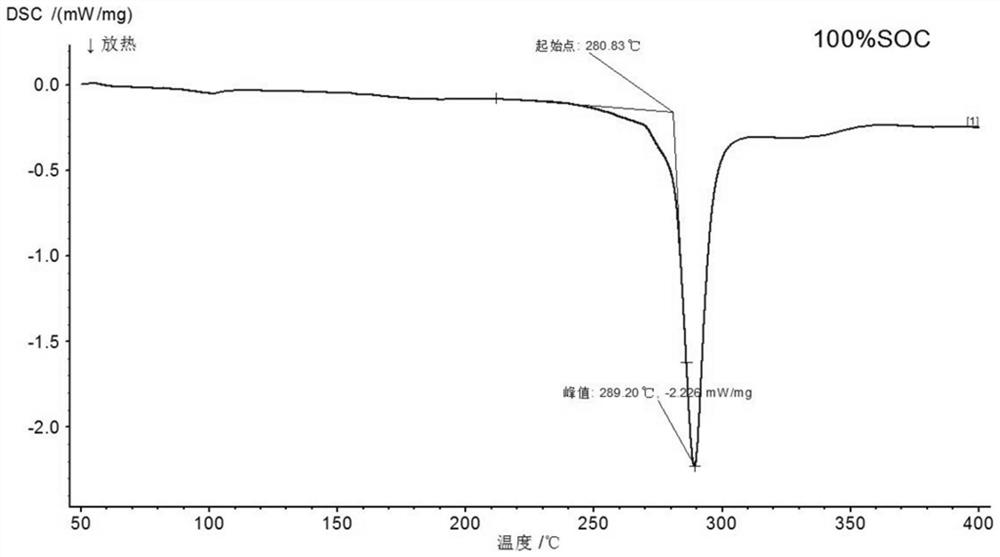

[0027] Under an inert atmosphere, put the negative electrode material powder into a high-pressure crucible, and conduct a DSC test at a heating rate of 10k / min. The test termination temperature is 400°C, and the thermal decomposition temperature T of the negative electrode material is obtained. 2 = 280.83°C;

...

Embodiment 2

[0030] S1. Set the preset temperature T=120°C;

[0031] S2. Under an inert atmosphere, disassemble the LFP battery cell under 100% SOC state to obtain the positive pole piece, then soak the positive pole piece in DMC for 30 minutes to remove the electrolyte, after drying, scrape powder and grind it to obtain Cathode material powder;

[0032] S3. Under an inert atmosphere, put the positive electrode material powder into an alumina crucible, and conduct a TG test at a heating rate of 10k / min. The termination temperature of the test is 800°C, and obtain the exothermic temperature T of the reaction between the positive electrode material and the electrolyte. 1 = 218.60°C;

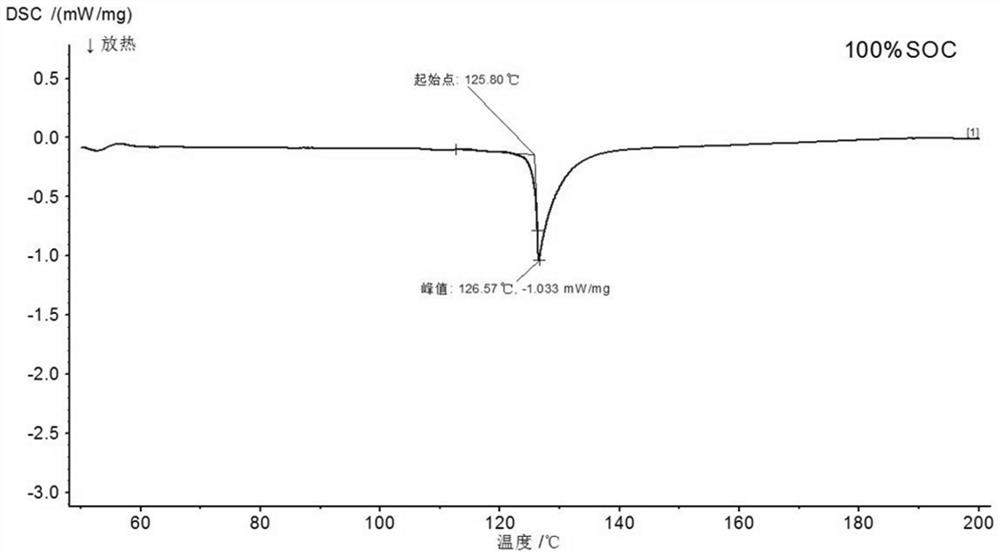

[0033] Under an inert atmosphere, put the positive electrode material powder into a high-pressure crucible, and conduct a DSC test at a heating rate of 10k / min. The termination temperature of the test is 200°C, and obtain the thermal decomposition temperature T of the positive electrode material. 2 =125.80°C;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com