Battery negative plate, preparation method thereof and lithium ion battery

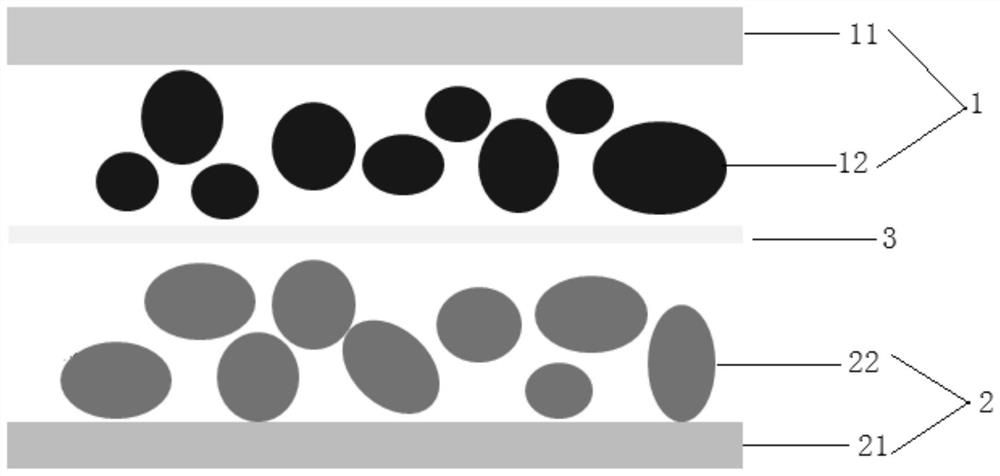

A lithium-ion battery and battery negative electrode technology, which is applied in the direction of electrode manufacturing, battery electrodes, electrode collector coating, etc., can solve the problems of reducing battery energy density, achieve improved power and safety, stable electrochemical performance, and internal small resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

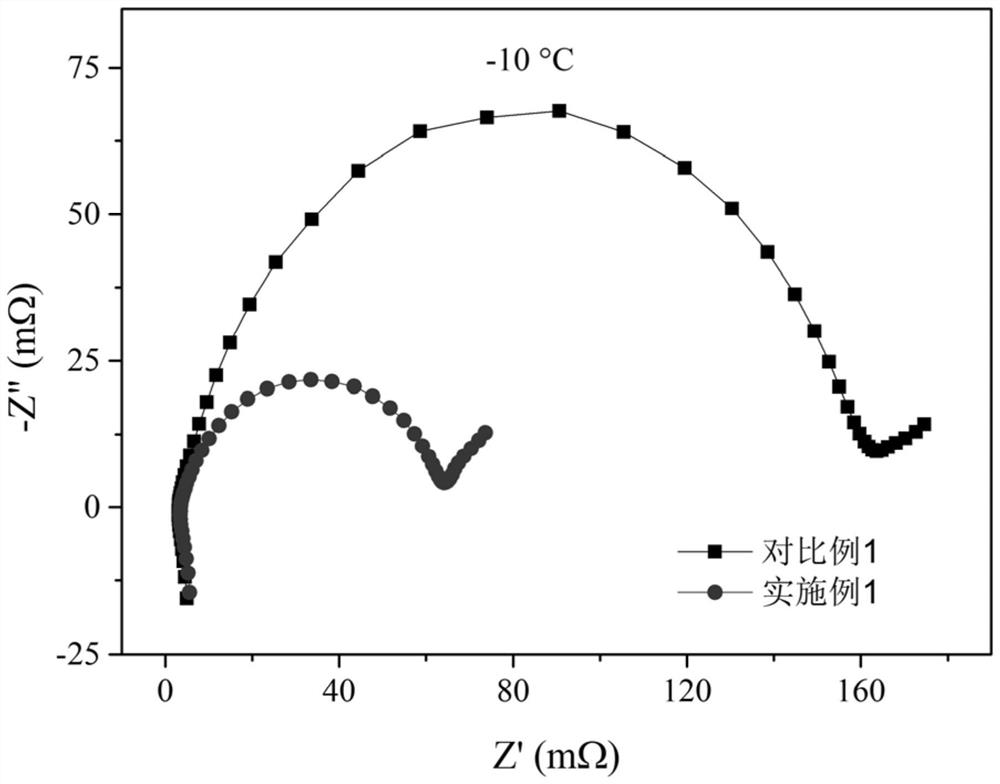

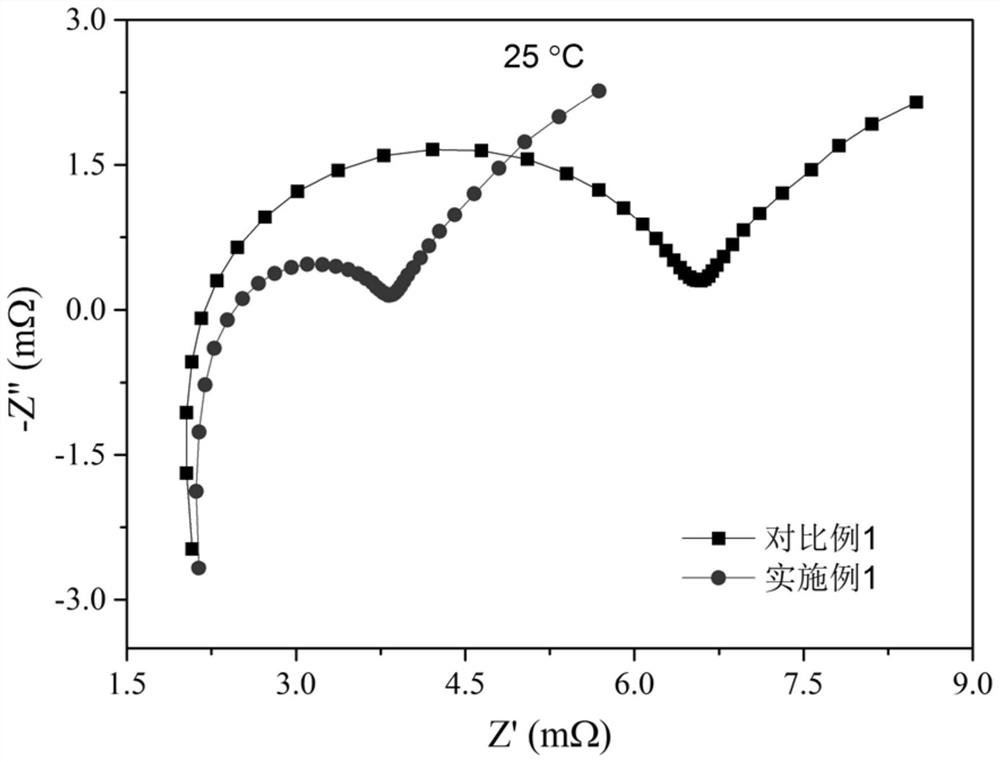

Embodiment 1

[0065] This example is prepared a battery negative electrode sheet.

[0066] The first active material is a artificial graphite, and the first conductive agent is a conductive carbon black (SP) and graphene, the first binder is CMC and SBR, dissolved in water to form an adhesive solution, with a first active material, first The conductive agent, as well as the mass ratio of the first binder is 92: 5: 3 is placed in a dual planetary pulper, and the self-rotating speed of the double planetary beating machine is 45-50 rpm, the non-rotation speed of 1500-1600 rpm is made of stirring The first slurry.

[0067] Press the first slurry to 59-65 g / m 2 The surface density is coated on one surface of the copper foil, drying such that the aqueous content is less than 1000 ppm to form a first active material layer.

[0068] The second active material is hard carbon, the second conductive agent is SP, and the second adhesive is PVDF, dissolved in such as N-methylpyrrolidone forming a second b...

Embodiment 2

[0071] This example is prepared a battery negative electrode sheet.

[0072] The first active material is natural graphite, the first conductive agent is a conductive carbon black (SP) and graphene, the first binder is CMC and SBR, dissolved in water to form a binder solution, with a first active material, first The conductive agent, as well as the mass ratio of the first binder is 92: 5: 3 is placed in a dual planetary pulper, and the self-rotating speed of the double planetary beating machine is 45-50 rpm, the non-rotation speed of 1500-1600 rpm is made of stirring The first slurry.

[0073] Press the first slurry to 59-65 g / m 2 The surface density is coated on one surface of the copper foil, drying such that the aqueous content is less than 1000 ppm to form a first active material layer.

[0074] The second active substance is activated carbon, the second conductive agent is carbon fiber, and the second binder is PVDF, dissolved in such as N-methylpyrrolidone forming a second...

Embodiment 3

[0077] This example is prepared a battery negative electrode sheet.

[0078] The first active substance is Si and artificial graphite, the first conductive agent is a conductive carbon black (SP) and graphene, the first binder is CMC and SBR, dissolved in water to form a binder solution, with Si and artificial graphite, The mass ratio of the first conductive agent, and the first binder is 10: 82: 5: 3 placed in a dual planetary beating machine, and the self-rotating speed of the double planetary beater is 45-50 rpm, the non-unversion speed is 1500-1600 rpm. The first slurry is made at the speed.

[0079] Press the first slurry to 59-65 g / m 2 The surface density is coated on one surface of the copper foil, drying such that the aqueous content is less than 1000 ppm to form a first active material layer.

[0080] The second active material is a hard carbon. The second conductive agent is carbon fiber, and the second binder is PVDF, dissolved in such as N-methylpyrrolidone forming a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com