Irradiation sterilization method for frozen products

A technology for irradiating and sterilizing frozen products, which is applied in food preservation, food science, and applications. It can solve the problems of poor long-term fresh-keeping effect of meat quality, and achieve good long-term fresh-keeping effect, enhanced effect, and good fresh-keeping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

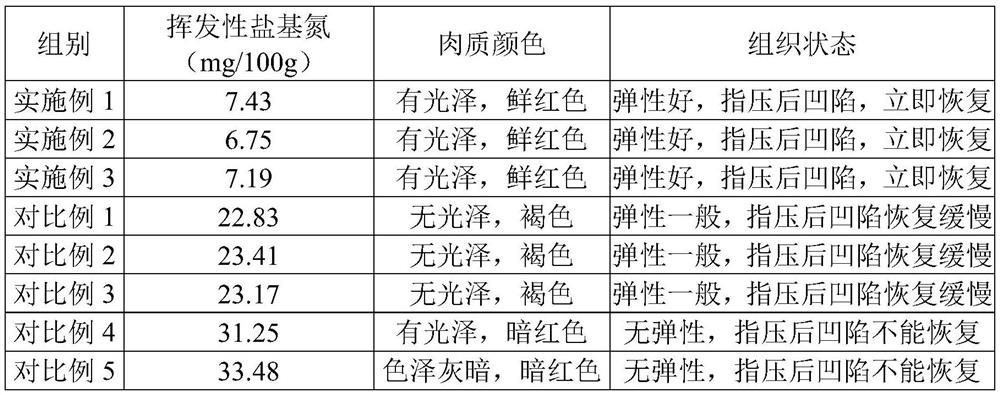

Examples

Embodiment 1

[0030] Embodiment 1 A kind of irradiation sterilization method of frozen product

[0031] The irradiation sterilization method of described frozen product, comprises the steps:

[0032] S1. Clean the beef products at 0°C, cut them into meat pieces with a thickness of 6cm, soak them in the preservative for 20 minutes, then drain them, absorb the water, and set aside;

[0033] S2. After the meat pieces obtained in step S1 are subjected to 10 min of high-voltage pulse electric field treatment, they are respectively packed into aseptic packaging bags to obtain prepackaged meat products; the high-voltage pulse electric field strength is 20 kV / cm, and the pulse width is 1 μs , the pulse frequency is 300Hz;

[0034] S3. Place the pre-packaged meat products obtained in step S2 at room temperature, turn on the electron beam accelerator for double-sided irradiation treatment, and the irradiation dose is 6 kGy; the time for the electron beam irradiation treatment is 5 minutes, and the b...

Embodiment 2

[0039] Embodiment 2 A kind of irradiation sterilization method of frozen product

[0040] The irradiation sterilization method of described frozen product, comprises the steps:

[0041] S1. Wash the beef products at 5°C, cut into meat pieces with a thickness of 12cm, and soak them in the preservative for 25min, then drain, absorb the water, and set aside;

[0042] S2. After the meat pieces obtained in step S1 are subjected to 20 min of high-voltage pulse electric field treatment, they are respectively packed into aseptic packaging bags to obtain prepackaged meat products; the high-voltage pulse electric field intensity is 30 kV / cm, and the pulse width is 2.5 μs, the pulse frequency is 500Hz;

[0043] S3. Place the pre-packaged meat products obtained in step S2 at room temperature, turn on the electron beam accelerator for double-sided irradiation treatment, and the irradiation dose is 8kGy; the time for the electron beam irradiation treatment is 12min, and the beam intensity 1...

Embodiment 3

[0048] Embodiment 3 A kind of radiation sterilization method of frozen product

[0049] The irradiation sterilization method of described frozen product, comprises the steps:

[0050] S1. Wash the beef products at 10°C, cut them into meat pieces with a thickness of 20cm, soak them in the preservative for 30min, then drain them, absorb the water, and set aside;

[0051] S2. After the meat pieces obtained in step S1 are subjected to 30 minutes of high-voltage pulse electric field treatment, they are respectively packed into aseptic packaging bags to obtain prepackaged meat products; the high-voltage pulse electric field strength is 40kV / cm, and the pulse width is 5μs , the pulse frequency is 680Hz;

[0052] S3. Place the pre-packaged meat products obtained in step S2 at room temperature, turn on the electron beam accelerator for double-sided irradiation treatment, and the irradiation dose is 10 kGy; the time for the electron beam irradiation treatment is 15 minutes, and the bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com