Zn-SAPO-17/SAPO-44 composite molecular sieve as well as preparation method and application thereof

A technology of SAPO-44 and SAPO-17, applied in the field of composite molecular sieve and its preparation, to achieve the effect of good catalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

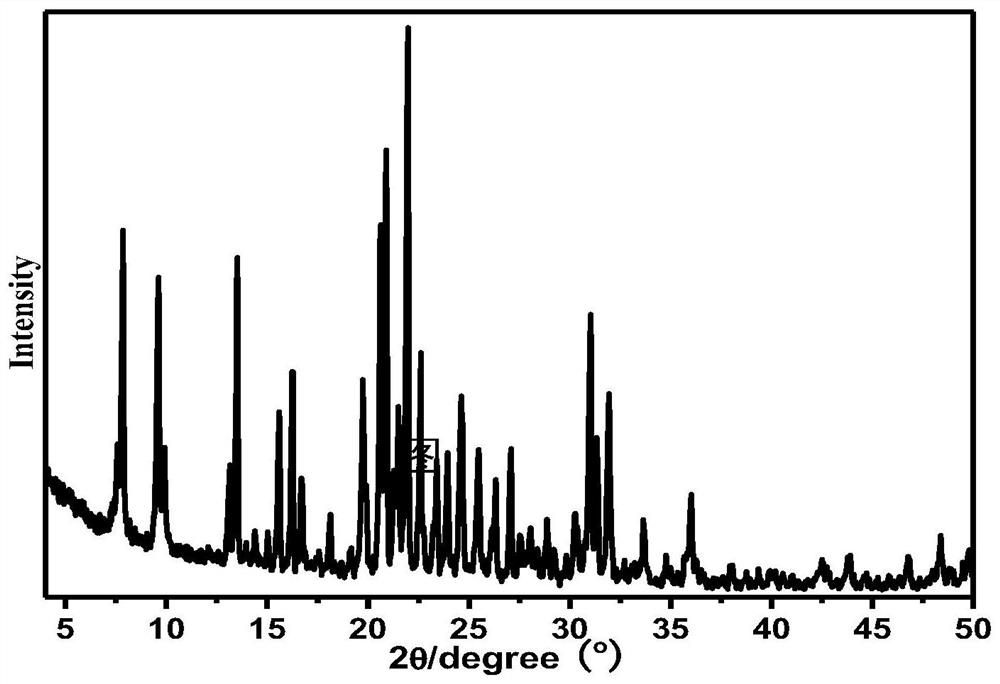

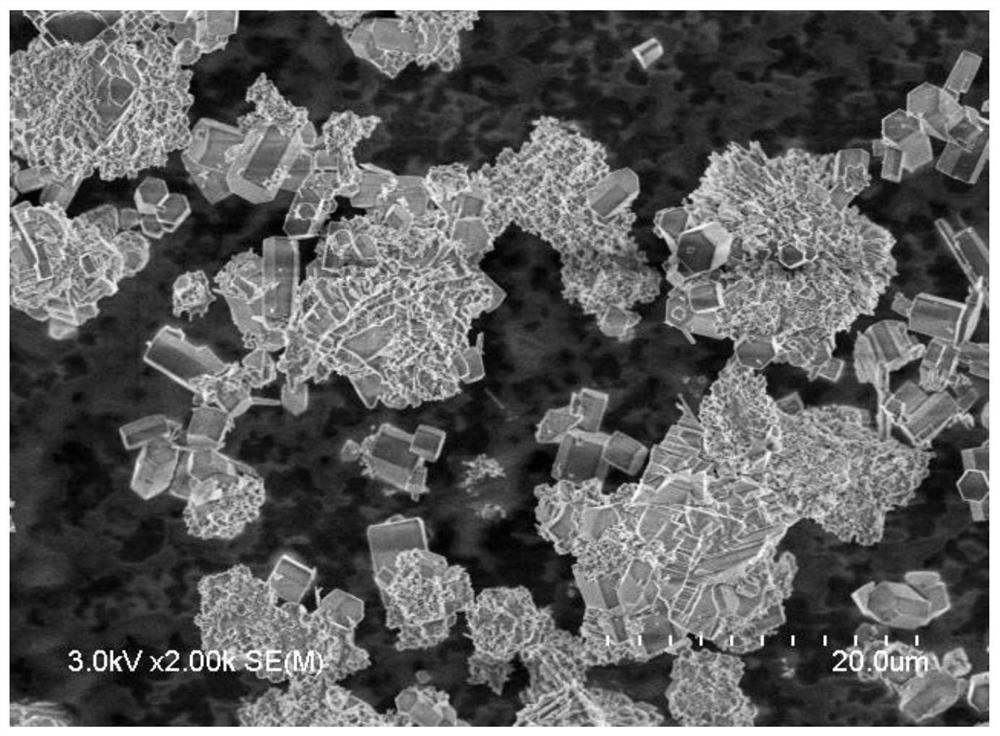

[0047] Synthesis of Zn-SAPO-17 / SAPO-44 Composite Molecular Sieves

[0048] Take by weighing 102.98g of aluminum nitrate [Al(NO 3 ) 3 9H 2 O, purity ≥ 98wt.%, 0.27mol] and 26.36g of zinc acetate [Zn(OAc) 2 2H 2 O, 0.12mol] was dissolved in 562.95mL of deionized water, stirred evenly to form solution C 0 , after which 25.53g of phosphoric acid [H 3 PO 4 , purity ≥ 85wt.%, 0.14mol], 858.46g of tetraethylammonium hydroxide [TEAOH, 25wt.% aqueous solution, 1.46mol] into C 0 solution, after fully stirring for 0.5h, solution C was obtained 1 , after which 3.24g of acidic silica sol [SiO 2 , 40wt.%, 0.13mol] and 721.45g of cyclohexylamine [HCHA, 99wt.%, 7.28mol] into C 1 In the solution, fully stirred for 0.5h and placed at 60°C for 12h to obtain a crystallized mixture, then placed at 170°C for 3.5d, the product was filtered and washed, then dried at 80°C for 12h, then heated to 450°C, and roasted at a constant temperature The product was obtained after 12h, which was design...

Embodiment 2

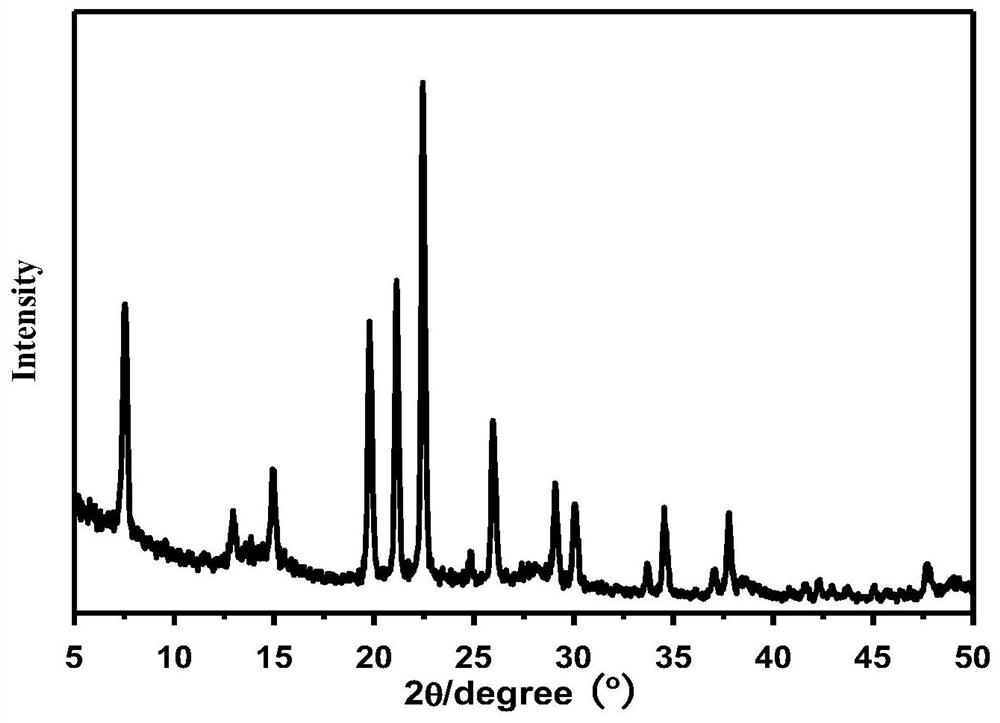

[0051] Synthesis of Zn-SAPO-17 / SAPO-44 Composite Molecular Sieves

[0052] Weigh 22220.34g of aluminum isopropoxide [Al(iPr) 3 , purity ≥99wt.%, 108.79mol] and 13180.86g of zinc nitrate [Zn(NO 3 ) 2 ·6H 2 O, 44.31mol] was dissolved in 177077.94mL of deionized water, stirred evenly to form solution C 0 , after which 9532.56g of phosphoric acid [H 3 PO 4 , purity ≥ 85wt.%, 82.68mol] and 428566.40g of tetraethylammonium hydroxide [TEAOH, 50wt.% aqueous solution, 1454.74mol] into the C solution, continue to stir for 5h to obtain solution C 1 , after which 326.22g of white carbon black [SiO 2 , 99wt.%, 5.44mol], 396860.31g of cyclohexylamine [HCHA, 4008.69mol into C 1 In the solution, stirred for 5 hours and placed at 120°C for 1 hour to obtain a crystallized mixture, then placed at 180°C for 2.5 days of crystallization, the product was filtered and washed, then dried at 120°C for 6 hours, then heated to 600°C, and roasted at a constant temperature for 4 hours. The product ...

Embodiment 3

[0054] Synthesis of Zn-SAPO-17 / SAPO-44 Composite Molecular Sieves

[0055] Weigh 1092.92g of aluminum sulfate [Al 2 (SO 4 )3 18H 2 O, purity ≥98wt.%, 1.64mol] and 188.63g of zinc sulfate [ZnSO 4 ·7H 2 O, 0.66mol] was dissolved in 5371.02mL of deionized water, stirred evenly to form solution C 0 , after which 187.19g of phosphoric acid [H 3 PO 4 , 85%wt., 1.62mol], 14770.04g of tetraethylammonium bromide [TEABr, 70.28mol] were put into solution C, and stirring was continued for 1.5h to obtain solution C 1 , after which 5.82g of silica [SiO 2 , 99wt.%, 0.10mol], 3968.19g of cyclohexylamine [HCHA, 40.01mol] into C 1 In the solution, stirred for 2.5h and placed at 100°C for 3h to obtain a crystallized mixture, then placed at 175°C for 3d, the product was filtered and washed, then dried at 110°C for 8h, then heated to 500°C, and roasted at a constant temperature for 8h to obtain The product is denoted as ZSS-3, and the reactant stoichiometric ratio (molar ratio) of this sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com