Low-dielectric-constant ceramic dielectric material for low-temperature sintered MLCC and preparation method thereof

A technology of low dielectric constant and ceramic medium, which is applied in the field of low-permittivity ceramic dielectric material and its preparation for low-temperature sintered MLCC. Poor performance and other problems, to achieve the effect of low cost of raw materials and processes, stable dielectric properties, and low dielectric loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The present invention also provides a method for preparing the above-mentioned low-dielectric constant ceramic dielectric material for MLCC sintered at low temperature, comprising the following steps:

[0029] (1) According to the chemical composition aMgO-bCaO-cTiO 2 -dBaO-eB 2 o 3 -fSiO 2 -gLi 2O carry out batching to each starting raw material, mix raw material with deionized water as dispersion medium; Wherein, a, b, c, d, e, f, g represent molar percentage independently respectively, and satisfy following condition: 45% mol≤a≤55%mol, 2%mol≤b≤5%mol, 20%mol≤c≤30%mol, 5%mol≤d≤15%mol, 5%mol≤e≤15%mol, 5% mol≤f≤15%mol, 5%mol≤g≤15%mol, a+b+c+d+e+f+g=100mol%;

[0030] The starting raw materials for preparing the ceramic dielectric material are not limited to the oxides of each element, and can be replaced by carbonates, nitrates, organic metal salts, etc. of each constituent element, and the purity of each starting material is greater than 99%, but also No special re...

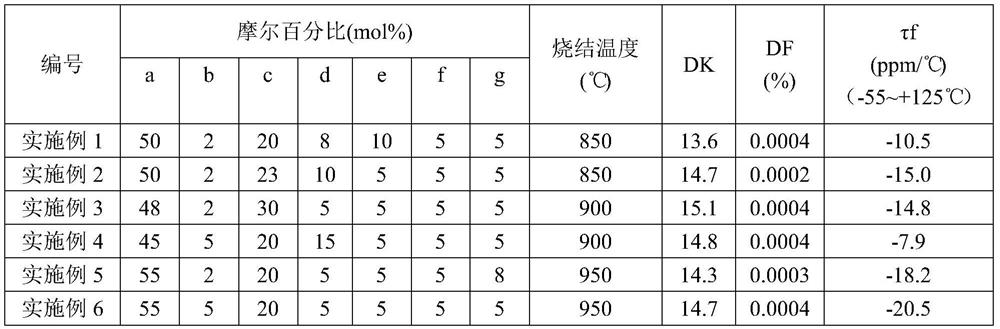

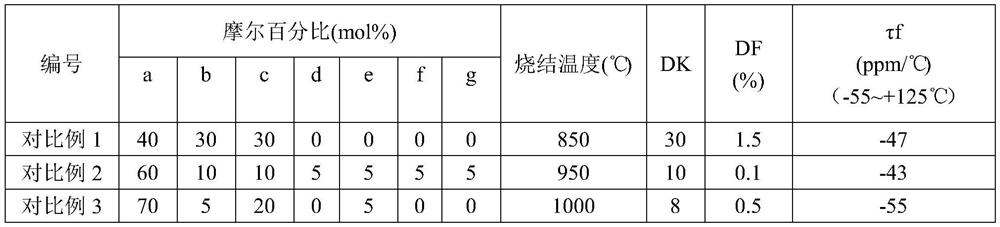

Embodiment 1-6

[0042] The preparation method of low dielectric constant ceramic dielectric material for MLCC sintered at low temperature comprises the following steps:

[0043] (1) According to the chemical composition aMgO-bCaO-cTiO 2 -dBaO-eB 2 o 3 -fSiO 2 -gLi 2 O to MgO, CaO, TiO 2 , BaO, B 2 o 3 , SiO 2 , Li 2 O is used for batching, and the raw materials are mixed with deionized water as the dispersion medium; wherein, a, b, c, d, e, f, and g respectively independently represent molar percentages, and the specific values are as shown in Table 1;

[0044] (2) Disperse and pulverize the mixed powder by ball milling process to make a slurry;

[0045] (3) After drying the slurry, calcining at 750°C for 5 hours to synthesize matrix powder;

[0046] (4) Disperse, pulverize and dry the above-mentioned matrix powder by ball milling process;

[0047] (5) Add polyvinyl alcohol solution to the base powder after step (4) and mix and then granulate, and press into a cylindrical ceramic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com