Glass coating with high adhesion and high light transmission and preparation method thereof

A technology with high adhesion and light transmission, applied in the field of coatings, can solve the problems of poor adhesion, water resistance and light transmission, difficulty in applying to glass surfaces, non-wear resistance, etc., achieve good adhesion and stability, improve Excellent light transmittance, water resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

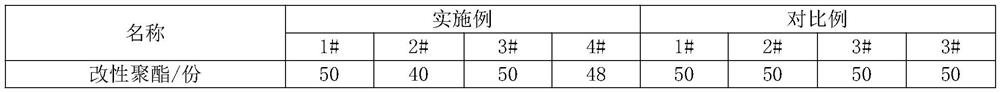

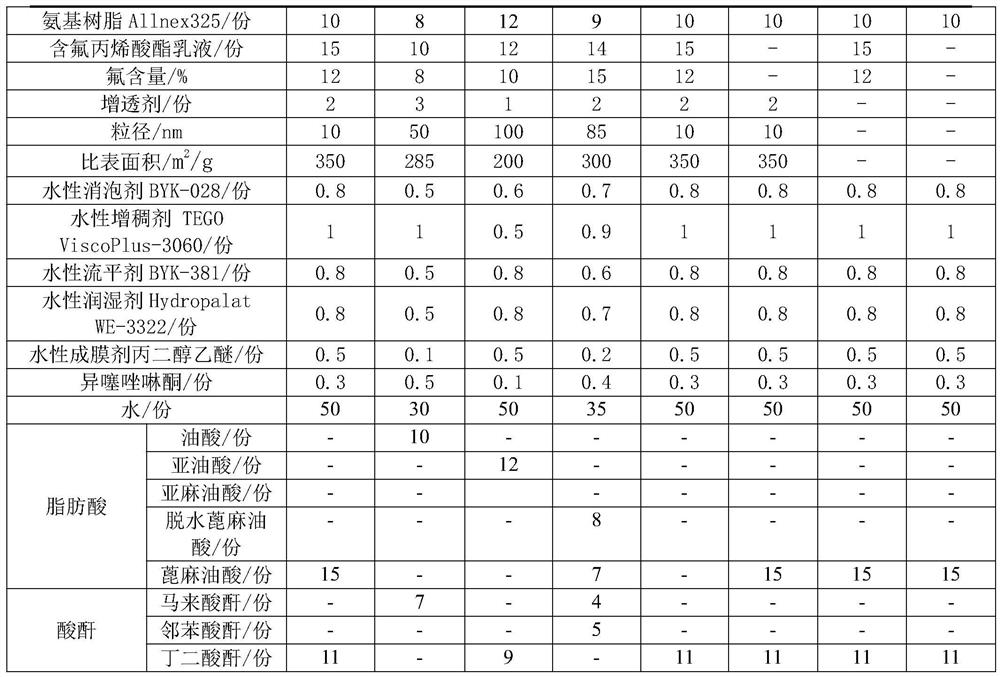

[0026] A high-adhesion and high-transparency coating for glass, prepared from the following raw materials by weight:

[0027] 50 parts of modified alkyd resin, 10 parts of amino resin Allnex32510, 15 parts of fluorine-containing acrylate emulsion with fluorine content of 12%, particle size of 10nm, specific surface area of 350m 2 / g anti-reflection agent 2 parts, defoamer BYK-0280.8 parts, thickener TEGOViscoPlus-30601 parts, leveling agent BYK-3810.8 parts, wetting agent Hydropalat WE-33220.8 parts, propylene glycol ether 0.5 parts, isothiazoline 0.3 parts of ketone, 50 parts of deionized water.

[0028] As a preference, the above-mentioned modified alkyd resin is prepared according to the following steps: (1) under the protection of nitrogen, add 15 parts of ricinoleic acid to the reaction kettle, heat up to 100 ° C under stirring, add 0.3 parts of zinc oxide, Continue to stir evenly; (2) 35 parts of isophthalic acid, 30 parts of trimethylolpropane, and 5 parts of ethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com