Fuel cell cathode multi-metal doped multi-element nonmetal oxygen reduction catalyst and preparation method thereof

A fuel cell cathode and non-metallic technology, applied in fuel cells, solid electrolyte fuel cells, battery electrodes, etc., can solve the problems of increasing the cost of PEFC catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

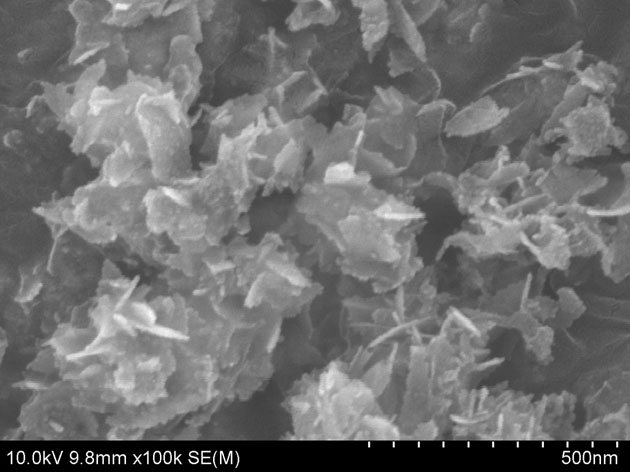

Image

Examples

Embodiment 1

[0043] A fuel cell cathode multi-metal-doped multi-element non-metallic oxygen reduction catalyst is prepared according to the following steps:

[0044] (1) Weigh 0.1g of palladium chloride and 20ml (0.4g / ml) of filtered graphene oxide in the same beaker, and stir at room temperature for 30min;

[0045] (2) Add 0.1 g of nickel chloride hexahydrate, ferric chloride, cobalt nitrate hexahydrate, 0.2 g of amine hydrofluoride and 40 ml of ethylene glycol into the beaker. carry out magnetic stirring;

[0046] (3) Suction filtration and separation of the above dispersion to obtain a solid, and drying the solid at 80° C. for 3 hours;

[0047] (4) The sample was heated in a tube furnace at 500°C for 2 h in a mixed atmosphere of hydrogen and argon. After heat treatment, a multi-metal doped multi-element non-metal oxygen reduction catalyst was obtained.

Embodiment 2

[0049] A fuel cell cathode multi-metal-doped multi-element non-metallic oxygen reduction catalyst, similar to Example 1, prepared according to the following steps:

[0050] (1) Weigh 0.5g of palladium chloride and 40ml (0.4g / ml) of filtered graphene oxide in the same beaker, and stir at room temperature for 30min;

[0051] (2) Add 0.5 g of nickel chloride hexahydrate, ferric chloride, cobalt nitrate hexahydrate, 0.3 g of amine hydrofluoride and 40 ml of ethylene glycol into the beaker. carry out magnetic stirring;

[0052] (3) After diluting and filtering the solution in deionized water, dry it at 80°C for 3 hours;

[0053] (4) Heat the sample in a tube furnace at 500°C for 2 h in a mixed atmosphere of hydrogen and argon to obtain the final sample.

Embodiment 3

[0055] A fuel cell cathode multi-metal-doped multi-element non-metallic oxygen reduction catalyst, similar to Example 1, prepared according to the following steps:

[0056](1) Weigh 0.3g of palladium chloride and 40ml (0.4g / ml) of filtered graphene oxide in the same beaker, and stir at room temperature for 30min;

[0057] (2) Add 0.3g of nickel chloride hexahydrate, ferric chloride, cobalt nitrate hexahydrate, 0.6g of amine hydrofluoride and 40ml of ethylene glycol into the beaker. carry out magnetic stirring;

[0058] (3) After diluting and filtering the solution in deionized water, dry it at 80°C for 3 hours;

[0059] (4) Heat the sample in a tube furnace at 500°C for 2 h in a mixed atmosphere of hydrogen and argon to obtain the final sample.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com