A kind of distributed feedback laser and its preparation method

A distributed feedback, laser technology, applied in the field of lasers, can solve the problem of the difference of the conduction band energy level affecting the performance of the device, and achieve the effect of improving the performance of the device, reducing the resistance, and reducing the size of the parasitic resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

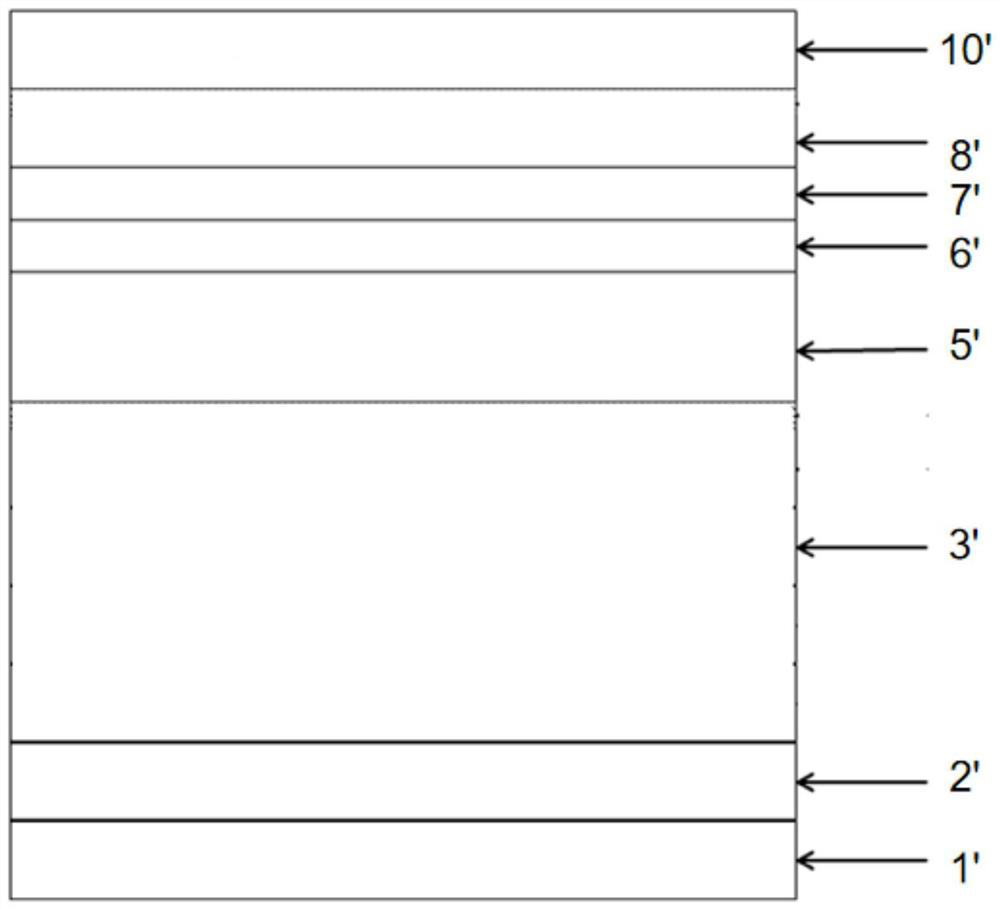

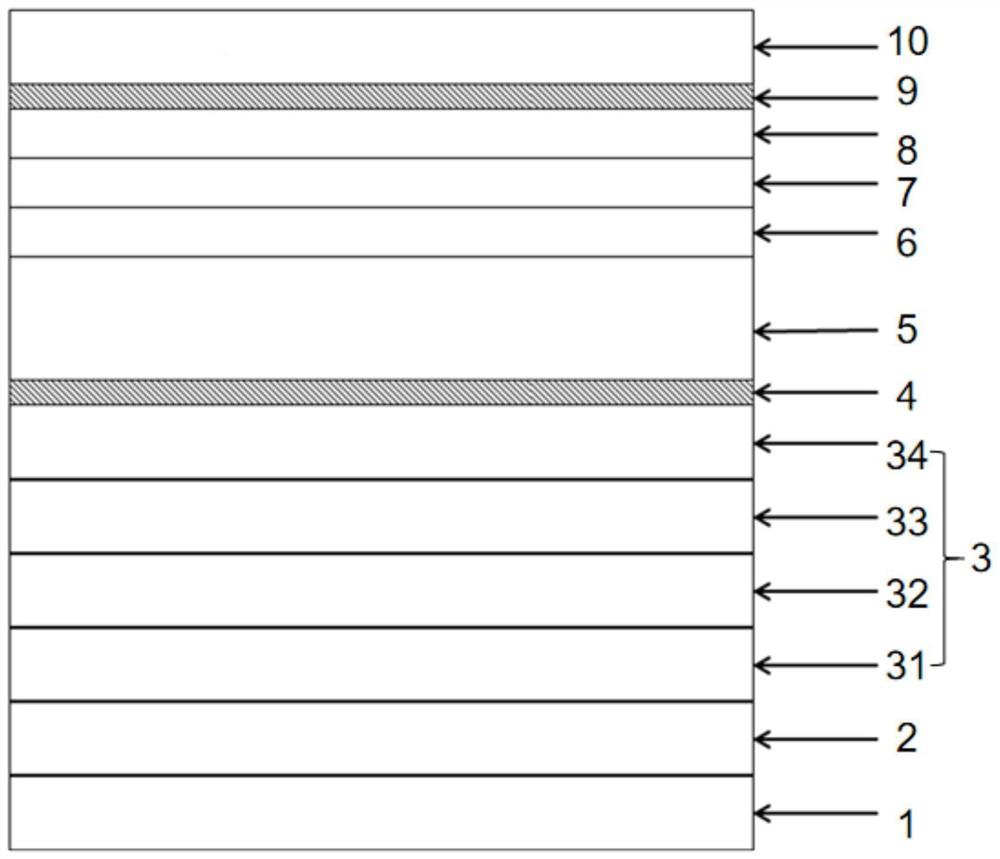

[0063] This embodiment provides a distributed feedback laser, refer to figure 2 , including a stacked second electrode (not shown in the figure), an InP substrate 1, an N-type InP buffer layer 2, an InGaAlAs semiconductor layer 3, a first P-type insertion layer 4, a P-type InP transition layer 5, and a grating layer 6. The grating cover layer 7, the P-type InP optical confinement layer 8, the P-type InGaAs ohmic contact layer 10 and the first electrode (not shown in the figure), wherein the first P-type insertion layer 4 is (InGaAlAs) 1-x (InP) x Material. The InGaAlAs semiconductor layer 3 includes a stacked N-type InGaAlAs confinement layer 31, an undoped InGaAlAs first waveguide layer 32, an undoped InGaAlAs active layer 33, and an undoped InGaAlAs second waveguide layer 34. The undoped InGaAlAs The doped InGaAlAs second waveguide layer 34 is disposed between the non-doped InGaAlAs active layer 33 and the first P-type insertion layer 4 .

[0064] In the above-mentioned ...

Embodiment 2

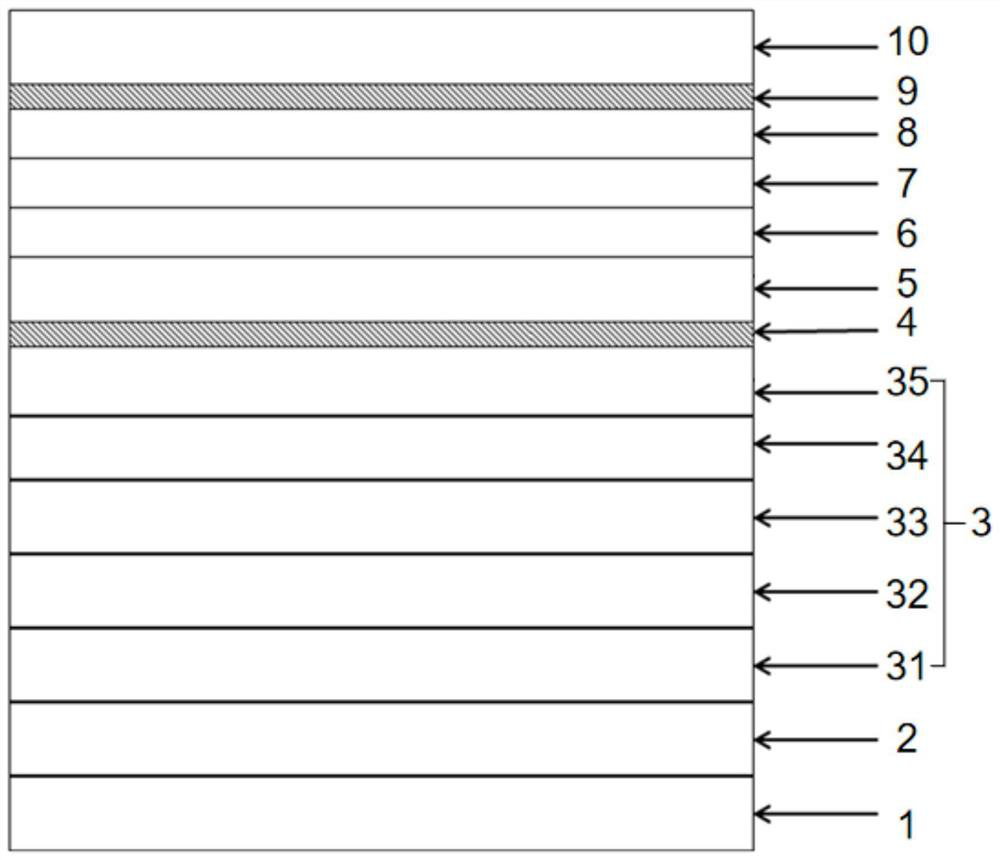

[0118] This embodiment provides a distributed feedback laser, refer to image 3 , including a stacked second electrode (not shown in the figure), an InP substrate 1, an N-type InP buffer layer 2, an InGaAlAs semiconductor layer 3, a first P-type insertion layer 4, a P-type InP transition layer 5, and a grating layer 6. A grating covering layer 7, a P-type InP optical confinement layer 8, a P-type InGaAs ohmic contact layer 10, and a first electrode (not shown in the figure), wherein the first P-type insertion layer 4 is (InGaAlAs) 1-x (InP) xMaterial. The InGaAlAs semiconductor layer 3 includes an N-type InGaAlAs confinement layer 31, a non-doped InGaAlAs first waveguide layer 32, a non-doped InGaAlAs active layer 33, a non-doped InGaAlAs second waveguide layer 34 and a P-type InGaAlAs confinement layer 31. layer 35, the P-type InGaAlAs confinement layer 35 is disposed between the non-doped InGaAlAs second waveguide layer 34 and the first P-type insertion layer 4, and the P-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com