Composite membrane with middle layer for forward osmosis of organic solvent and preparation method and application of composite membrane

A technology of organic solvent and intermediate layer, which is applied in the field of composite membrane with intermediate layer for organic solvent forward osmosis and its preparation. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

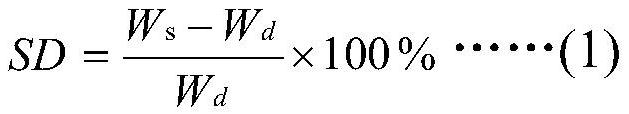

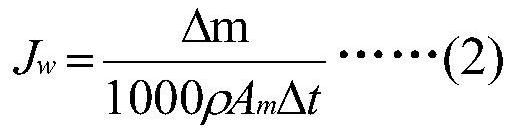

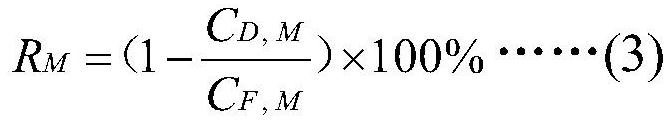

[0027] A composite membrane with an intermediate layer for organic solvent forward osmosis, which is composed of a support layer, an intermediate layer and a dense separation layer; the material of the support layer is polyimide, and the intermediate layer is composed of cyclodextrin supramolecular polymerization composition, the material of the separation layer is polyamide, the porosity of the support layer is 20-85%; Supramolecular polymer; the separation layer has a thickness of 0.1-5 μm, and its preparation method includes the following steps:

[0028] (1) Preparation of polyimide base film:

[0029] The polyimide, the solvent N-methylpyrrolidone and the polyethylene glycol are mixed so that the mass percent concentration of the polymer is 15-20%. Stir mechanically at 70°C to obtain the casting solution, and let it stand for 12 hours for defoaming. Then transfer the casting solution to a clean flat glass plate and scrape the film with a scraper. At a certain temperatur...

Embodiment 1

[0044] A composite membrane with an intermediate layer for organic solvent forward osmosis, which is composed of a support layer, an intermediate layer and a dense separation layer; the material of the support layer is polyimide, and the intermediate layer is composed of cyclodextrin supramolecular polymerization Composition, the material of described separating layer is polyamide, and its preparation method comprises the following steps:

[0045] (1) Dry 5g of polyimide in an oven at 80°C for 12 hours, mix polyimide, solvent N-methylpyrrolidone and polyethylene glycol according to the mass ratio of 18:16:66, and dry at 70°C Under mechanical stirring for 8 hours, a homogeneous polyimide casting solution was obtained. Let it stand for defoaming for 12 hours, then transfer the casting solution to a clean and flat glass plate, and scrape the film with a spatula. The scraped film was transferred to a deionized water coagulation bath to solidify at room temperature; then the obtai...

Embodiment 2

[0050] A composite membrane with an intermediate layer for organic solvent forward osmosis, which is composed of a support layer, an intermediate layer and a dense separation layer; the material of the support layer is polyimide, and the intermediate layer is composed of cyclodextrin supramolecular polymerization Composition, the material of described separating layer is polyamide, and its preparation method comprises the following steps:

[0051] (1) Dry 5g of polyimide in an oven at 80°C for 12 hours, mix polyimide, solvent N-methylpyrrolidone and polyethylene glycol according to the mass ratio of 18:16:66, and dry at 70°C Under mechanical stirring for 8 hours, a homogeneous polyimide casting solution was obtained. Let it stand for defoaming for 12 hours, then transfer the casting solution to a clean and flat glass plate, and scrape the film with a spatula. Immediately soak the scraped film at room temperature into a coagulation bath of deionized water, the solvent N-methyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com