Preparation method of quantum dot material

A quantum dot material and quantum dot technology, which are applied in the field of flat panel display, can solve the problem of low input and output, and achieve the effects of cost saving, reduction of surface lattice defects, and good optoelectronic performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

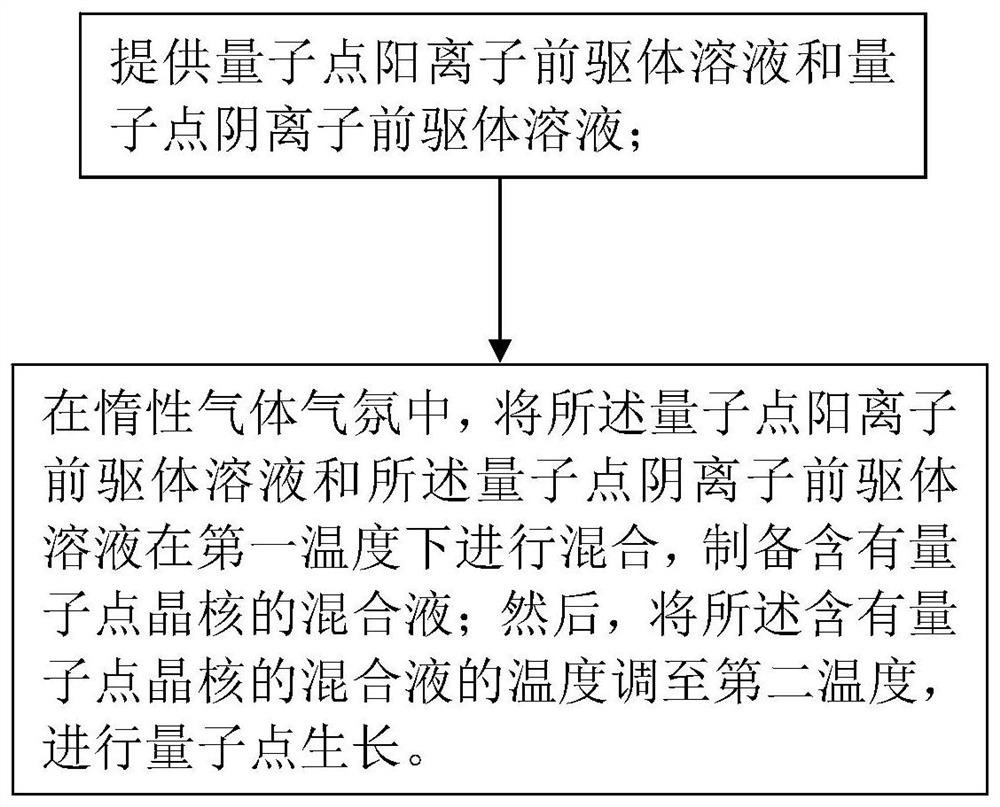

[0018] A preparation method of quantum dot material, such as figure 1 shown, including the following steps:

[0019] S01, providing quantum dot cation precursor solution and quantum dot anion precursor solution;

[0020] S02. In an inert gas atmosphere, mix the quantum dot cation precursor solution and the quantum dot anion precursor solution at a first temperature to prepare a mixed solution containing quantum dot crystal nuclei; then, mix the quantum dot anion precursor solution containing The temperature of the mixed solution of quantum dot crystal nuclei is adjusted to the second temperature to carry out quantum dot growth;

[0021] Wherein, in the step of mixing the quantum dot cation precursor solution and the quantum dot anion precursor solution at a first temperature, add a mixture of primary amine and secondary phosphine and the quantum dot cation precursor solution and / or Or the quantum dot anion precursor solution is mixed;

[0022] The secondary phosphine has th...

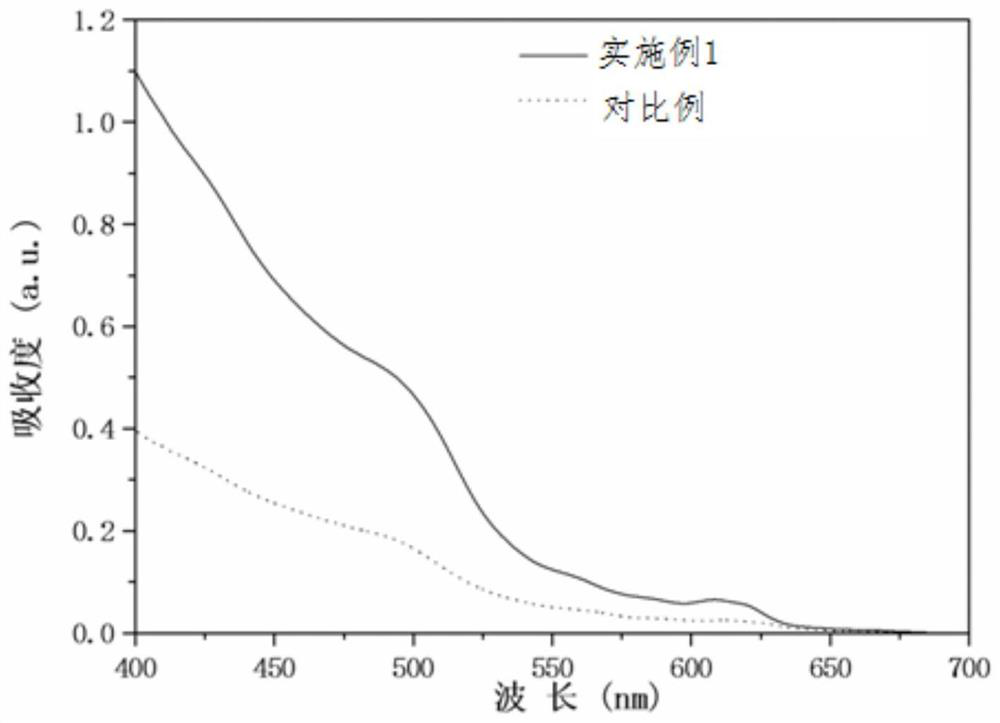

Embodiment 1

[0046] This embodiment prepares a kind of preparation method of quantum dot material CdZnSe, specifically comprises the following steps:

[0047] S11. Weigh 0.2mmol of CdO, 5mmol of ZnO, 5mL of oleic acid and 15mL of octadecene, add them to a 50mL three-necked bottle for mixing, and heat to 240°C to obtain a clear quantum dot cation precursor solution; then , adding 0.5mL di-tert-butylphosphine to the quantum dot cation precursor solution for mixing, and vacuuming for 30min to remove water vapor and air in the solution to obtain a quantum dot cation precursor solution containing di-tert-butylphosphine;

[0048] S12, weighing the selenium element and TBP, dissolving the selenium element in the TBP, and preparing a quantum dot anion precursor solution with a concentration of 1M;

[0049] S13. Under a nitrogen atmosphere, raise the temperature of the quantum dot cation precursor solution containing di-tert-butylphosphine prepared in step S11 to 310°C, quickly inject 3mL of the qu...

Embodiment 2

[0052] In this embodiment, a quantum dot material CdSe is prepared, which specifically includes the following steps:

[0053] S21. Weigh 0.5mmol of CdO, 1mL of oleic acid and 9mL of octadecene, add them into a 25mL three-necked bottle for mixing, and heat to 240°C to obtain a clear quantum dot cation precursor solution; then, in the quantum dot Add 1mL n-octylamine to the cationic precursor solution for mixing, vacuumize for 20min to remove water vapor and air in the solution, and obtain a quantum dot cationic precursor solution containing n-octylamine;

[0054] S22, weighing the selenium element and TOP, dissolving the selenium element in the TOP, and preparing a quantum dot anion precursor solution with a concentration of 1M;

[0055] S23. Under a nitrogen atmosphere, raise the temperature of the n-octylamine-containing quantum dot cation precursor solution prepared in step S21 to 280° C., quickly inject the quantum dot anion precursor solution prepared in step S22, and then...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Half width | aaaaa | aaaaa |

| Emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com