Method for producing electrolytic copper foil

A technology of electrolytic copper foil, manufacturing method, applied in electrolytic process, electroforming, electrode, etc., can solve problems such as coarse roughness, peeling of tin plating layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

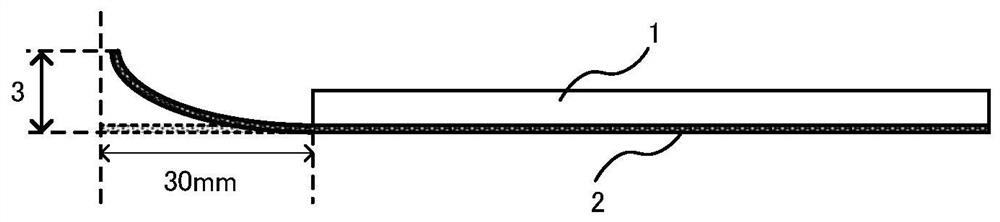

Image

Examples

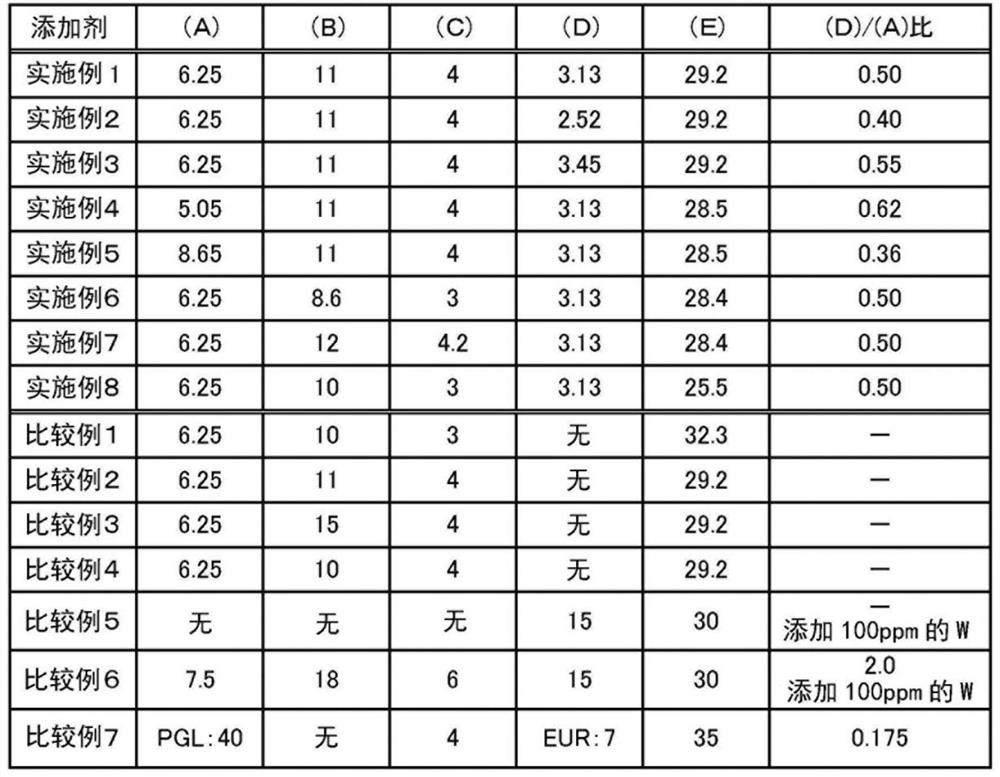

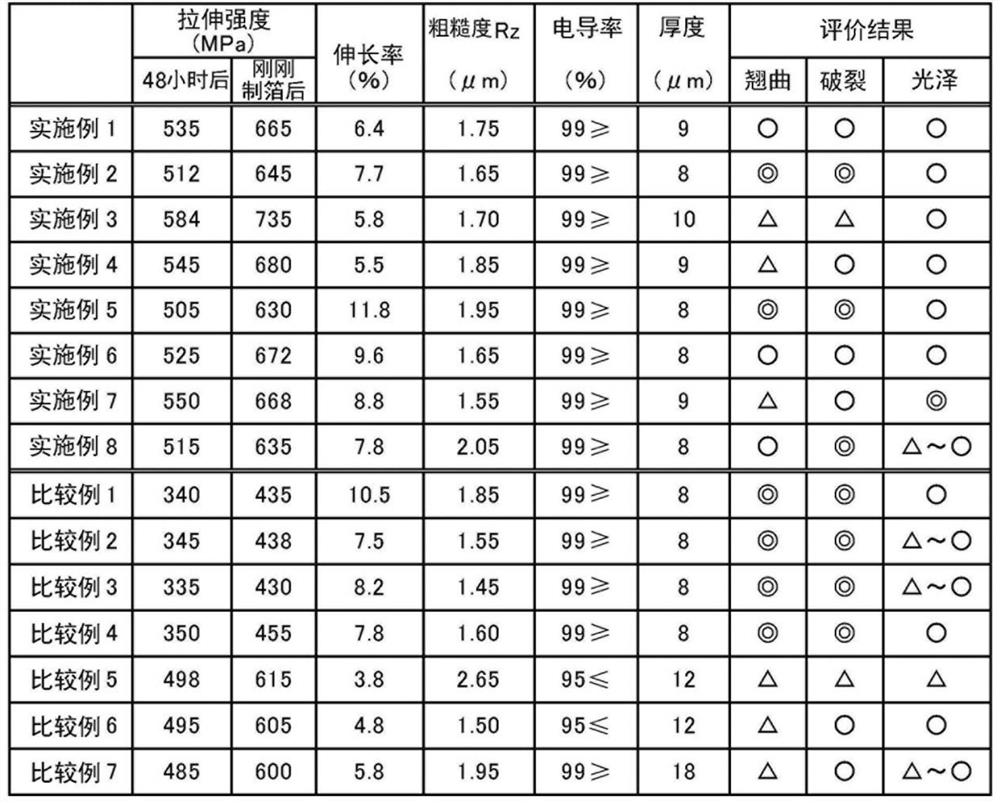

Embodiment 1~8、 comparative example 1~7

[0114] Preparation containing sulfuric acid (H 2 SO 4 ) 100g / L, and copper sulfate pentahydrate (CuSO 4 ·5H 2 (0) sulfuric acid-copper sulfate aqueous solution of 280g / L. Hereinafter, this electrolytic solution is referred to as "basic electrolytic solution".

[0115] As additives to be added to the above-mentioned basic electrolytic solution, the following components were respectively prepared.

[0116] Additives (A): hydroxyethyl cellulose with a molecular weight of 250,000, hydroxyethyl cellulose with a molecular weight of 500,000 (both manufactured by DAICEL FINECHEM Co., Ltd.), polyglycerin (manufactured by DAICEL CHEMICAL INDUSTRIES CO., abbreviated as PGL )

[0117] ・Additive (B): Collagen peptide with a molecular weight of 5000 (manufactured by Asahi Chemical Industry Co., Ltd.)

[0118] ・Additive (C): Sodium 3-mercapto-1-propanesulfonate (manufactured by Koei Chemicals Co., Ltd.)

[0119] ・Additive (D): Thiourea (manufactured by Nippon Chemical Industries), N,N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com