Combined denitration system and method for preheating section and tail flue of steel rolling heating furnace

A heating furnace and preheating section technology, applied in the field of flue gas denitrification, can solve the problems of increased production cost of steel rolling production enterprises, difficulty in accurately controlling the injection amount of ammonia gas, large fluctuation of steel rolling production, etc., and achieves good load adaptability and saving. The effect of external denitration space, reducing investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

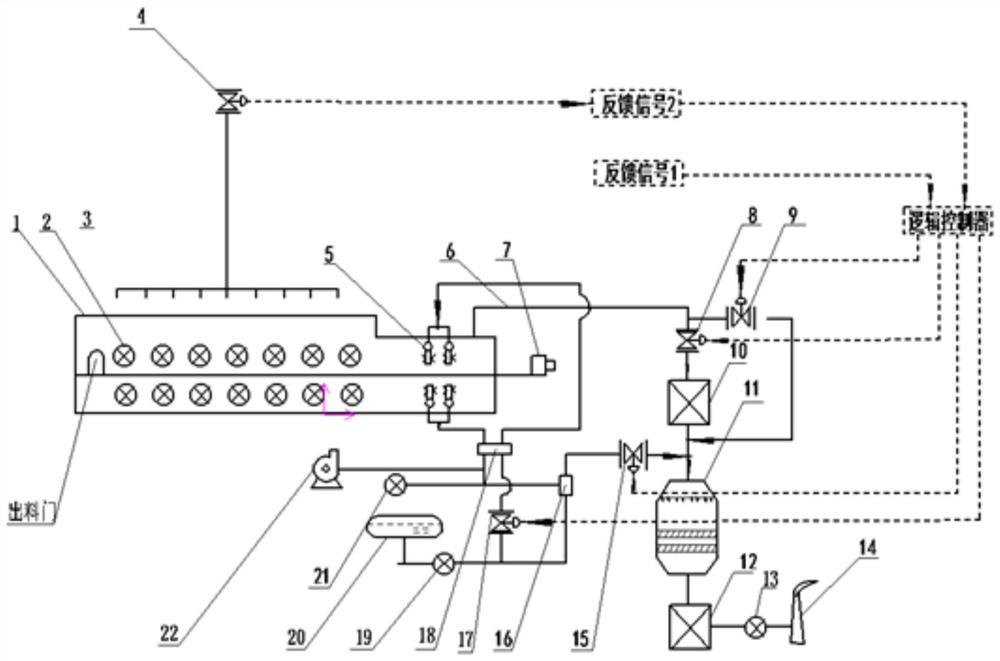

[0045] Such as figure 1 As shown, the joint denitrification system of the preheating section of the steel rolling heating furnace and the tail flue of the present invention includes a heating furnace, a steel pusher, an injection device, a high temperature air preheater, an SCR reactor, a low temperature air preheater, an SCR mixer, SNCR mixer, exhaust hood, air compressor, dilution fan, reducing agent storage device; the steel pusher is connected to the feeding end of the heating furnace for pushing the billet into the hearth of the heating furnace, and the injection device is set in the heating furnace The tail of the preheating section; the furnace roof at the feed end of the heating furnace is connected to the high-temperature air preheater, SCR reactor, low-temperature air preheater and exhaust hood in sequence through the flue gas pipeline to discharge the flue gas to the outside; reduction The reductant storage device is connected to the injection device through the SNCR ...

Embodiment 2

[0054] On the basis of Example 1, taking a steel rolling heating furnace in a steel plant as an example, the hourly flue gas volume is 90000Nm 3 / h, NO in the flue gas before installing the denitrification device x Concentration 350-420mg / Nm 3 .

[0055] After the above-mentioned heating furnace is equipped with the denitration system of the present invention, the SNCR system is installed in the preheating section of the heating furnace. Before the flue gas enters the SCR, it first passes through the two-stage high-temperature air preheater to cool down. In the flue, the flue gas passes through the SCR reactor and then passes through the first-stage low-temperature air preheater to cool down to below 150°C, and is discharged into the atmosphere through the induced draft fan.

[0056] When the two-stage denitrification process of SNCR and SCR is adopted, the total denitrification efficiency is over 95%, of which the SNCR denitrification efficiency is 40%, the SNCR denitrifica...

Embodiment 3

[0059] On the basis of embodiment 1, the denitrification method utilizing the combined denitrification system of the steel rolling heating furnace preheating section and tail flue of the present invention comprises the following steps:

[0060] (1) The reducing agent solution in the reducing agent storage device passes through the SNCR regulating valve according to the NO x The concentration of the reducing agent is adjusted, and it will be completely vaporized under the action of the air compressor and high temperature, so that the ammonia is converted into NH 3 After the gas is removed, it is sent to the SNCR mixer through the first reducing agent pipeline for mixing and standby;

[0061] (2) The steel pusher transports the steel billet to the furnace of the heating furnace, burns fuel in the burner to heat the steel billet, and generates high-temperature flue gas in the heating furnace. Spray the NH in step (1) 3 Gas reducing agent, so that it can be fully mixed with flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com