System and process for strengthening toluene hydrogenation reaction

A technology of hydrogenation reaction and toluene, which is applied in the system field of strengthening toluene hydrogenation reaction, can solve the problem of high pressure, achieve low reaction pressure, improve utilization rate, and high reflection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

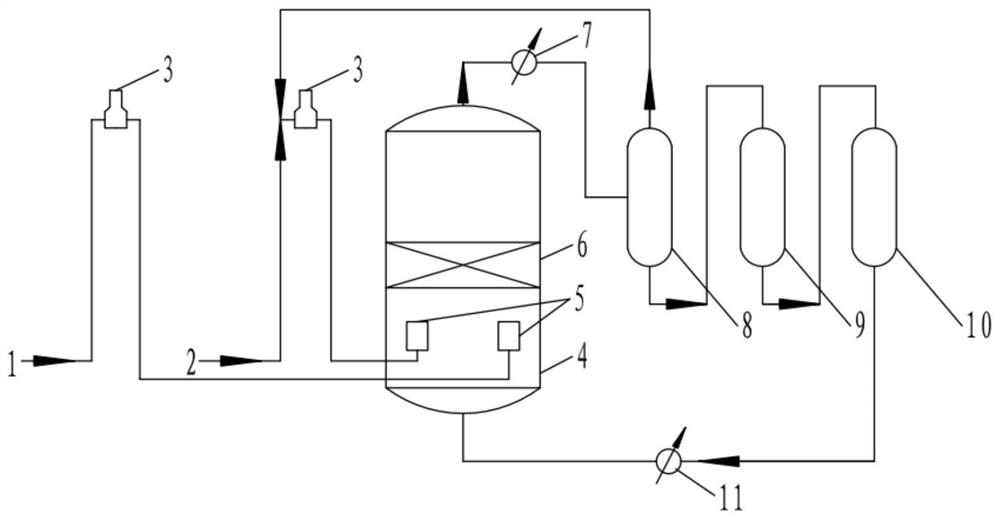

[0039] A micro-interface generator is installed at the reactor outlet of the feed oil pipeline and the hydrogen pipeline respectively, and its system structure is as follows figure 1 As shown, the operation period of the reactor is half a year, the reaction temperature is 500° C., the reaction pressure is 2 MPa, the yield of benzene is 97%-98.6%, and the purity of the produced benzene is more than 99.5%.

Embodiment 2

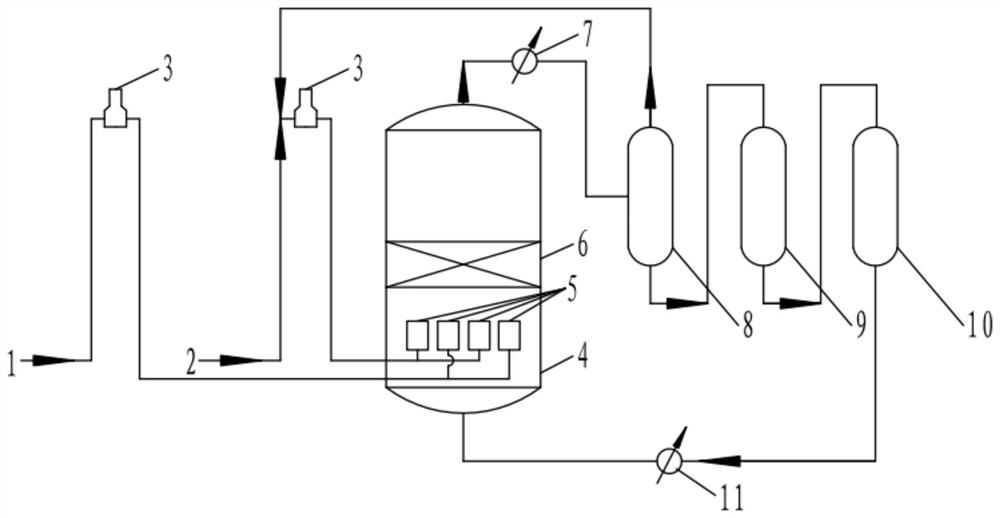

[0041] Two micro-interface generators are installed at the reactor outlets of the feed oil pipeline and the hydrogen pipeline respectively, and the system structure is as follows figure 2 As shown, the operation period of the reactor is half a year, the reaction temperature is 450° C., the reaction pressure is 1.4 MPa, the yield of benzene is 98%-99.5%, and the purity of the produced benzene is over 99.5%.

Embodiment 3

[0043]Three micro-interface generators are installed at the reactor outlets of the raw material oil pipeline and the hydrogen pipeline. The reactor operation period is half a year, the reaction temperature is 400°C, the reaction pressure is 1MPa, and the benzene yield is 97%-99.1%. , the purity of the prepared benzene is above 99.5%.

[0044] Compared with the traditional method of preparing benzene by catalytic dealkylation of alkylaromatics, the above-mentioned embodiment effectively reduces the reaction pressure and reaction temperature by installing a micro-interface generator, increases the reaction efficiency of hydrogen and raw oil, and reduces the amount of material and energy loss.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com