A method for selective hot corrosion assisted brazing of fiber-reinforced composites and metals

A composite material, fiber reinforced technology, used in metal processing equipment, welding equipment, welding/welding/cutting items, etc., can solve the problems of poor connection interface structure, large residual stress, and small ceramic application range, and improve the connection. Interfacial area, reducing residual stress, changing the effect of fracture path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

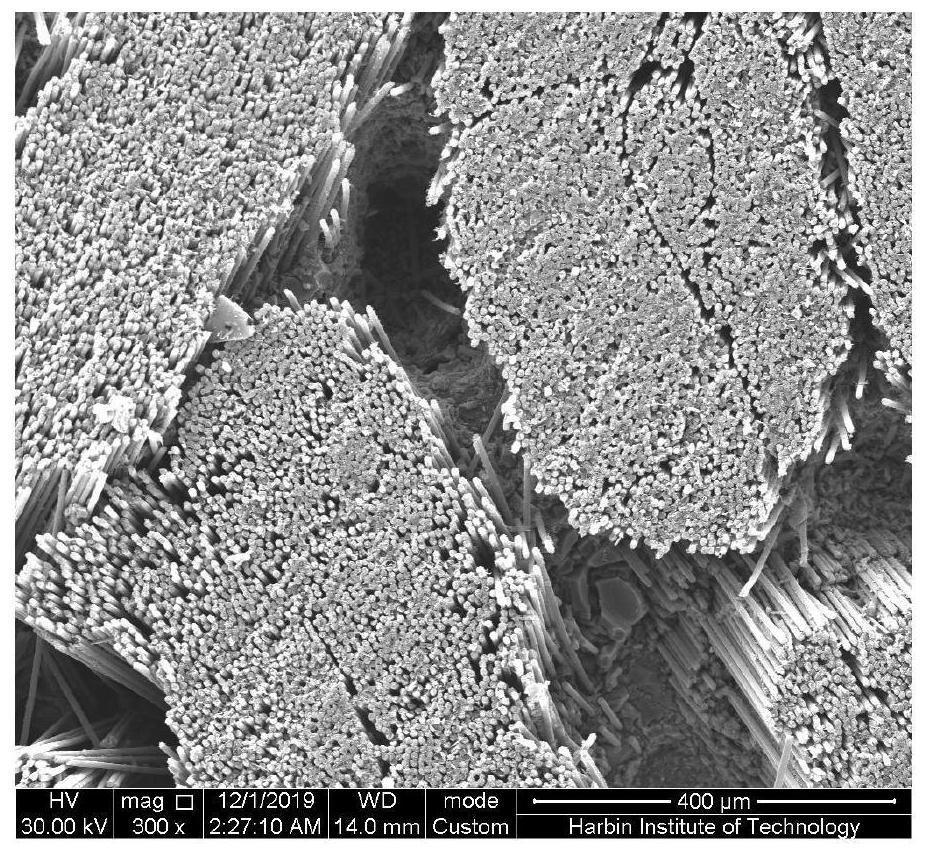

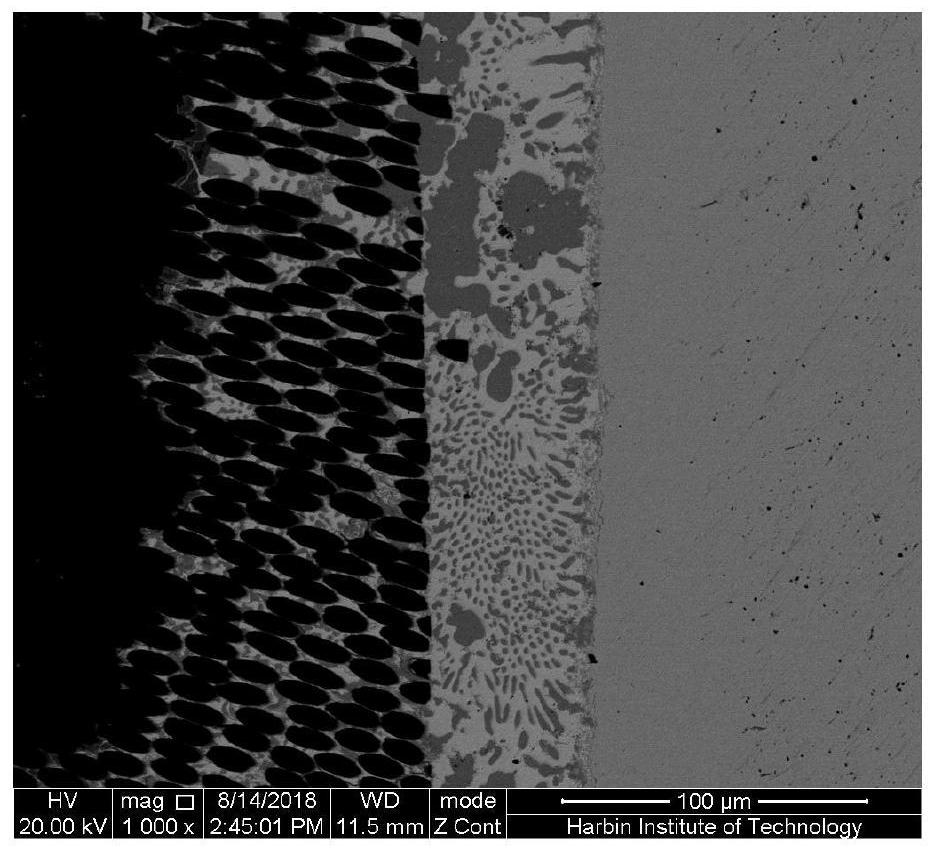

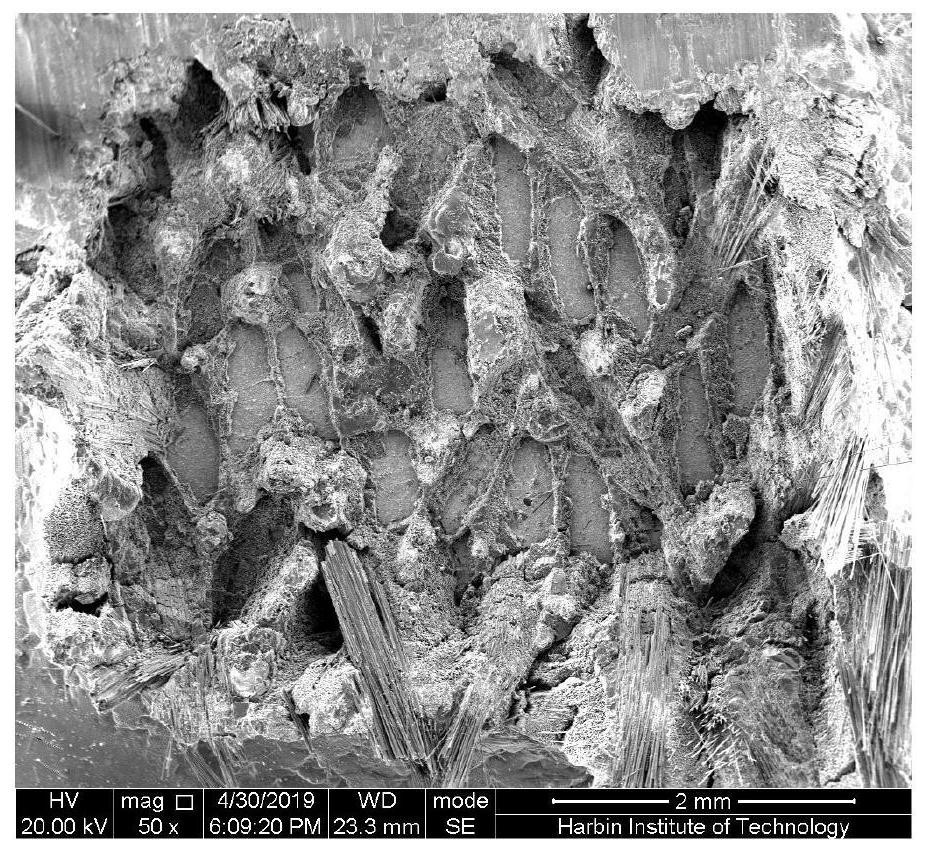

[0028] Specific Embodiment 1: In this embodiment, a method for selective thermal corrosion assisted brazing of fiber-reinforced composite materials and metals is carried out according to the following steps:

[0029] 1. Preparation of hot corrosion molten salt:

[0030] Mix the alkaline oxidant, corrosion inhibitor and carbon powder to obtain a mixed powder, and then grind the mixed powder evenly to obtain a hot corrosion molten salt;

[0031] The mass percentage of the corrosion inhibitor in the hot corrosion molten salt is 5% to 30%; the mass percentage of the carbon powder in the hot corrosion molten salt is 1% to 5%;

[0032] 2. Preparation of thermal corrosion protection layer:

[0033] Cut the fiber-reinforced composite material and grind and polish each surface, use PVD process to plate Ni-Cr layer on the non-welding surface of the fiber-reinforced composite material, and then keep it warm for 10min under the condition of annealing temperature of 300℃~500℃ ~60min, aft...

specific Embodiment approach 2

[0043] Embodiment 2: This embodiment differs from Embodiment 1 in that the diameter of the carbon powder described in step 1 is 1 μm˜10 μm. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0044] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the purity of the alkaline oxidizing agent described in step 1 is 99.9%. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com