Method for transferring graphene film on metal substrate

A graphene film and metal substrate technology, applied in the field of two-dimensional materials, can solve the problems of graphene wrinkles or breakage, damage the integrity of graphene, etc., and achieve the effects of reducing cracks, ensuring contact, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

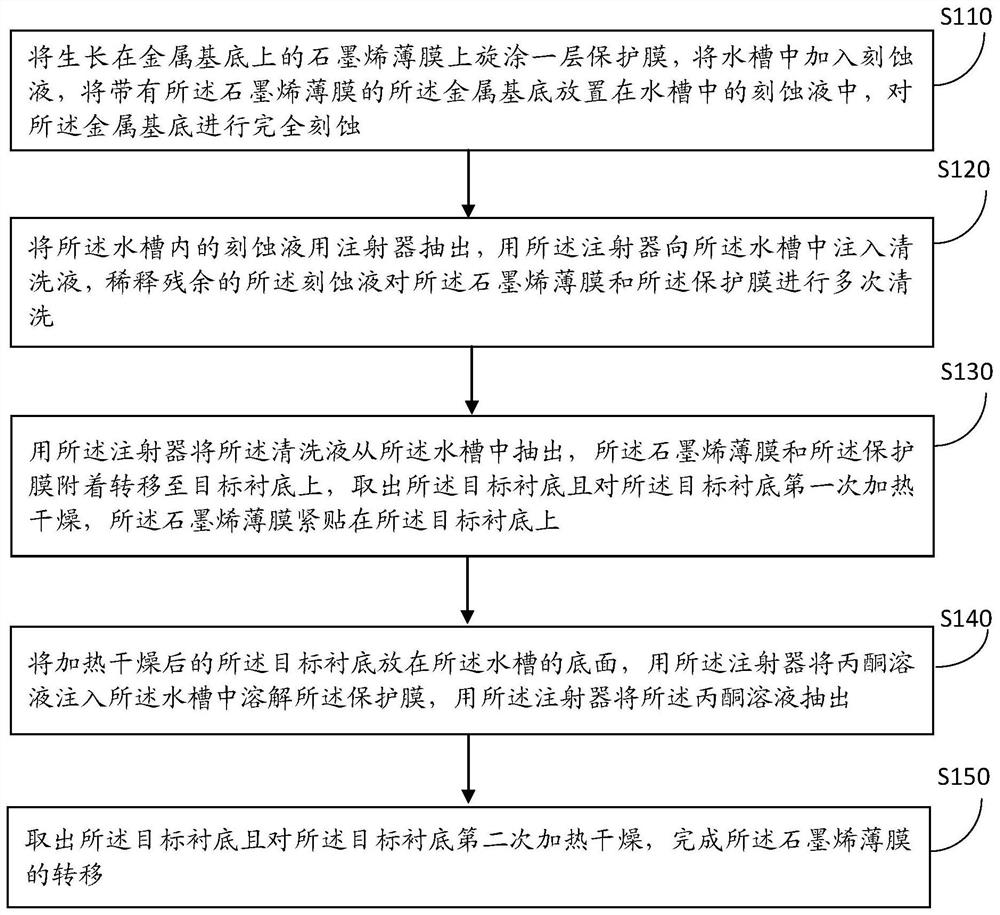

[0027] The embodiment of the present invention provides a method for transferring a graphene film on a metal substrate, please refer to figure 1 , image 3 , the method includes S110-S150:

[0028] S110: Spin-coat a protective film on the graphene film grown on the metal substrate, add an etching solution into the water tank, and place the metal substrate with the graphene film in the etching solution in the water tank , completely etching the metal base;

[0029] Further, the protective film is a PMMA protective film. Further, the etching solution is ammonium persulfate solution.

[0030] Specifically, a PMMA protective film will be spin-coated on the graphene film grown on the metal substrate. Add the etching solution ammonium persulfate solution to the water tank to the first scale of the water tank, such as 50 mL of the water tank. The metal base of the graphene thin film with a protective film is placed in the etching solution in the water tank, and the metal base is...

Embodiment 2

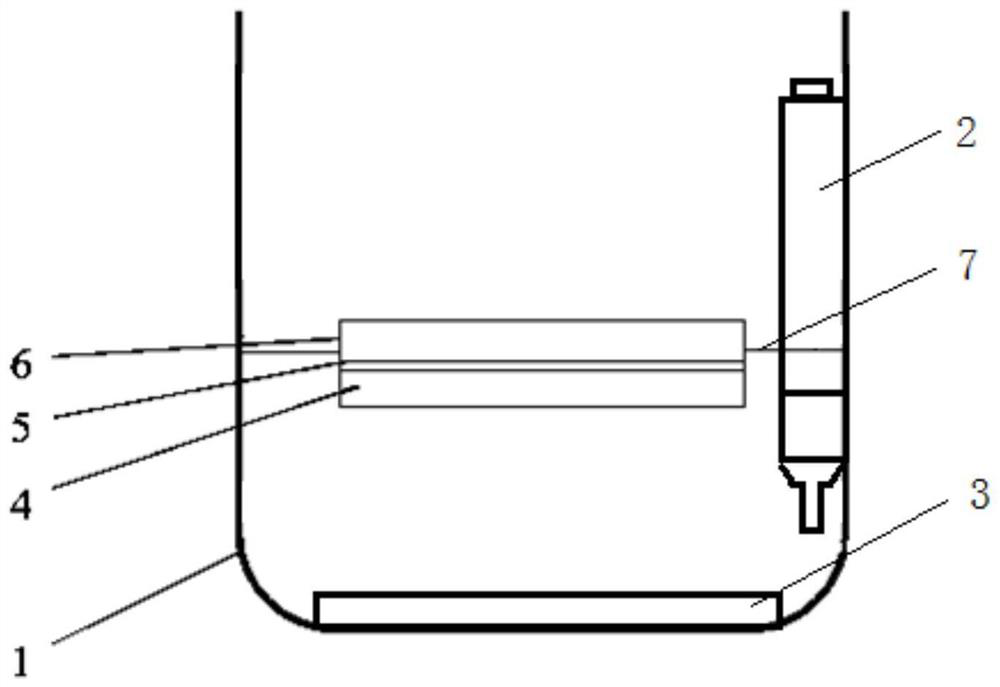

[0039] The embodiment of the present invention provides a device for transferring a graphene film on a metal substrate, please refer to figure 2 , the device includes:

[0040] Water tank 1; target substrate 3, the target substrate 3 is placed on the bottom surface of the water tank 1, and the area of the target substrate 3 is smaller than the bottom surface area of the water tank 1; etching solution 7, the etching The liquid 7 is filled in the water tank 1, and the etching liquid 7 has a first liquid level in the water tank 1;

[0041] Further, the volume of the water tank 1 ranges from 10ml to 1000mL. Further, the water tank 1 is made of polytetrafluoroethylene, ceramics, polycarbonate, glass or quartz.

[0042] Specifically, the embodiment of the present application provides a device for transferring a graphene film on a metal substrate, and the device includes: a water tank 1, a syringe 2, a target substrate 3, and the like. The volume of the water tank 1 in the em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com