Multi-type garbage pyrolysis system and multi-type garbage treatment method thereof

A multi-type, waste technology, used in energy input, special forms of dry distillation, coke ovens, etc., can solve the problem that the moisture content of the feed waste affects the stable operation of the pyrolysis gasification system, increases equipment investment and operating costs, and treats waste types. It can reduce the risk of dioxin, improve the utilization efficiency of heat and waste heat, and improve the efficiency of pyrolysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

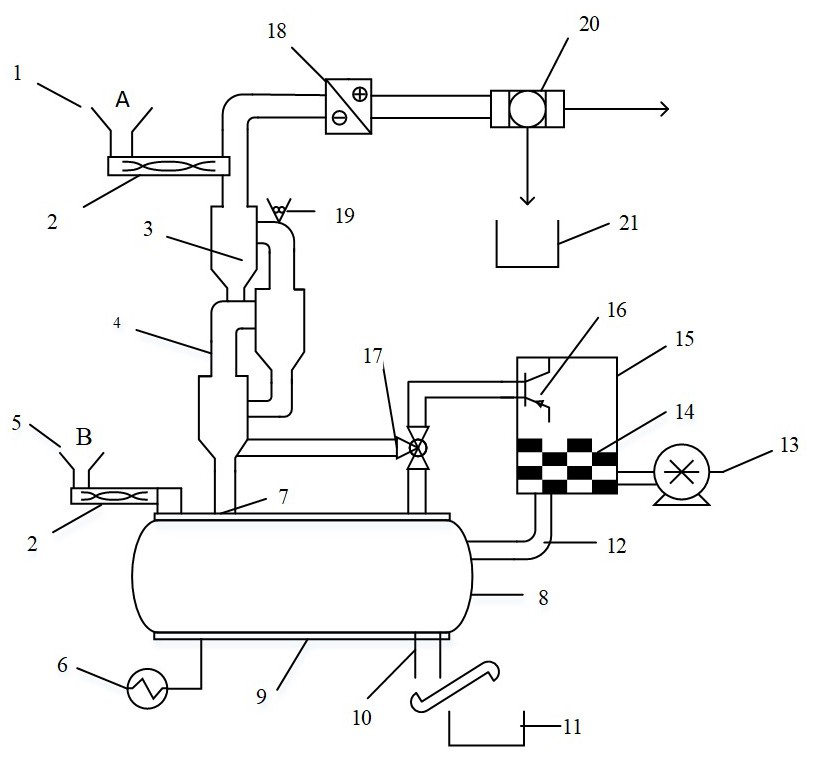

[0034] Embodiment 1: A multi-type garbage pyrolysis system and method, which is characterized in that it includes systems (1) garbage gradient preheating system, (2) pyrolysis system, (3) pyrolysis oil-gas combustion system, (4) Flue gas waste heat utilization system, (5) Pyrolysis reactor heating and temperature control system, (6) Tail gas treatment system.

[0035] (1) Garbage gradient preheating system: the system includes waste crushing hopper A with high moisture content and low calorific value, and multi-stage gradient preheaters connected vertically alternately. Carry out certain deacidification and denitrification synergistic pretreatment on flue gas;

[0036] (2) Pyrolysis system: the system includes waste crushing hopper B with low moisture content and high calorific value, pyrolysis reaction device, which includes gradient preheating waste feed inlet, heating temperature control device, flue gas insulation system, thermal Decomposition oil and gas outlet, pyrolysi...

Embodiment 2

[0043] Example 2: Use this system to carry out experiments on domestic waste collected and transported in different areas. Some of the domestic waste has a moisture content of about 65%, and some of the sieved domestic waste has a moisture content of about 30%. First, the domestic waste with a moisture content of 30% Put the garbage into the hopper B to crush the particle size to about 15mm, then use the heating and temperature control device to gradually increase the temperature of the pyrolysis reactor to 650°C, keep the pyrolysis temperature at 650°C for 2 hours, and remove the pyrolysis residue after the pyrolysis reaction Spiral to the hopper 11 through the outlet 10, the pyrolysis oil gas enters the combustion device 15 through the pyrolysis oil gas pipeline 12, and the pyrolysis oil gas burns in the porous medium through the igniter and air blowing, and the temperature is kept at about 850 ° C. After heating, it is porous The medium effectively preheats the air entering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com