Brain organoid in-vitro culture chip

A technology for in vitro culture and organoids, applied in tissue culture, tissue cell/virus culture devices, biochemical instruments, etc., can solve the problem of changing gene expression profiles, neurodevelopment, brain organoids with different sizes and shapes, and affecting the production of brain organoids. In order to achieve the effects of reducing pollution and damage, low preparation cost, and avoiding multiple transfers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

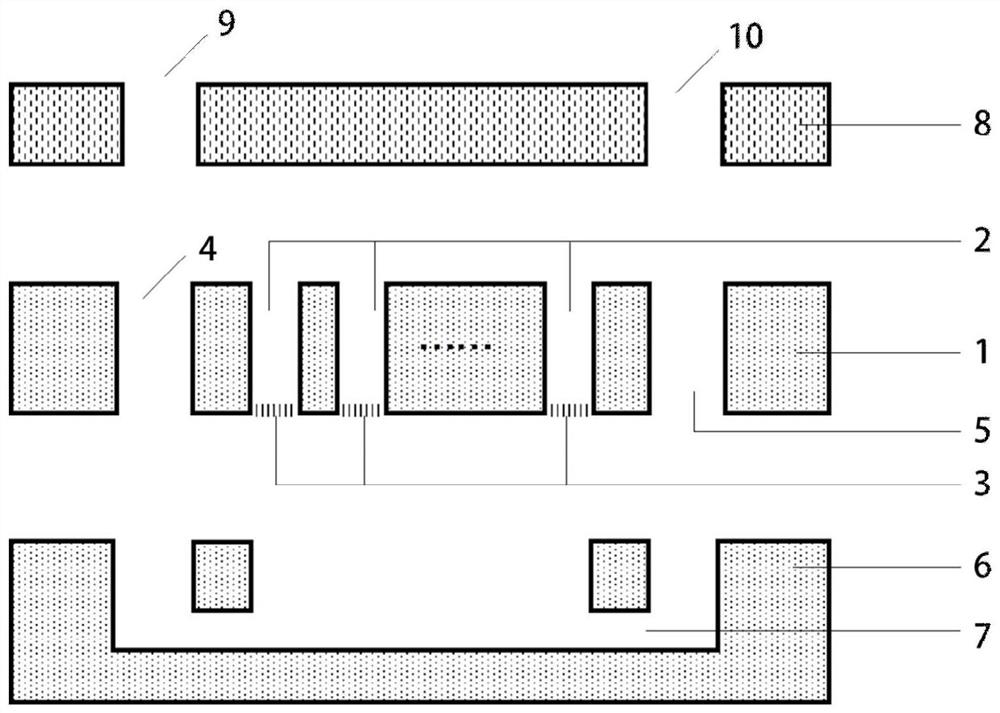

Embodiment 1

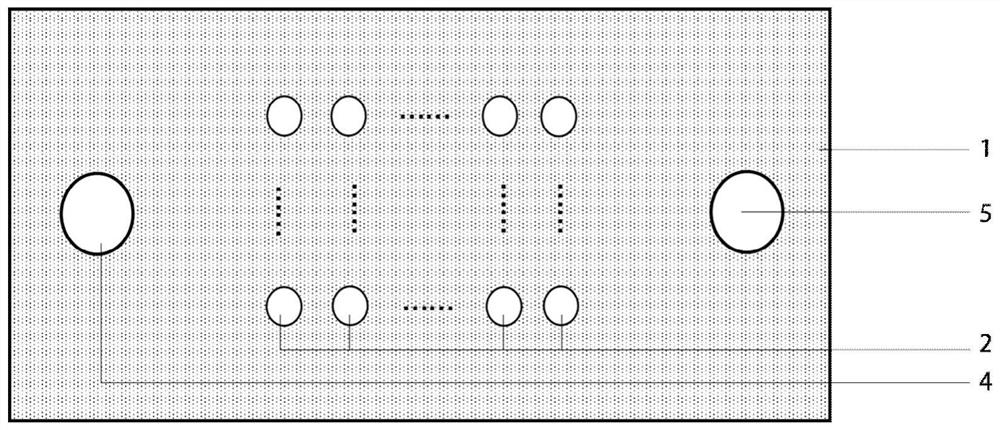

[0028] a. Preparation of the upper layer chip 1: use PDMS with a width of 3cm*length of 5cm, and cultivate a 4*4 hole array in the middle of the PDMS through mechanical drilling. The distance from the short edge is 18mm, the diameter of the entrance and exit is 4mm, the center of the circle is 8mm from the short edge, and 15mm from the long edge. Using a polymer microporous structure 3 with a diameter of 10 μm, the center of the microporous structure 3 is 25 mm away from the short edge and 15 mm away from the long edge, and the microporous structure 3 is connected to the culture hole by using a bonding process.

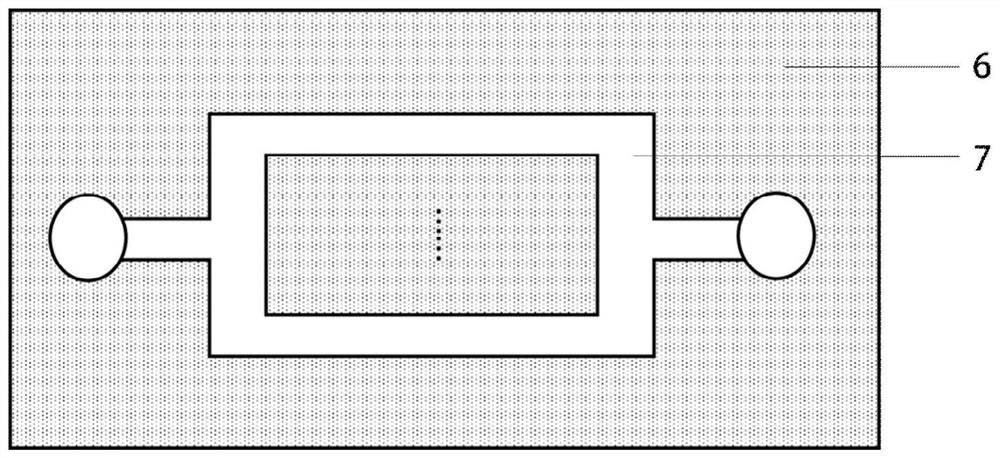

[0029] b. Preparation of the lower layer chip 6: use a quartz plate with a width of 3 cm * a length of 5 cm, cut a 4 mm circular hole in the quartz plate through laser micromachining, the center of the circle is 8 mm from the short edge, 15 mm from the long edge, and extend along the long direction A channel with a length of 5mm and a width of 2mm emerges, and after b...

Embodiment 2

[0036] a. Preparation of the upper layer chip 1: use PMMA with a width of 3cm*length of 5cm, and cultivate an 8*8 hole array in the middle of the PMMA by punching and drilling. , 17.5mm from the edge of the short side, 4mm in diameter of the entrance and exit, 8mm from the edge of the short side, and 15mm from the edge of the long side. Using a polymer microporous structure 3 with a diameter of 10 μm, the center of the microporous structure 3 is 25 mm away from the short edge and 15 mm away from the long edge, and the microporous structure 3 is connected to the culture hole by using a bonding process.

[0037] b. Preparation of the lower layer chip 6: use a quartz plate with a width of 3 cm * a length of 5 cm, cut a 4 mm circular hole in the quartz plate through laser micromachining, the center of the circle is 8 mm from the short edge, 15 mm from the long edge, and extend along the long direction Out of a channel with a length of 5mm and a width of 2mm, the back branch is 8 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com