Method for strengthening ferroalloy surface through laser melt injection

A technology of laser melting and ferroalloying, which is applied in the coating process of metal materials, coating, etc., can solve the problems of unclear process parameters and high technical difficulty, so as to ensure the strengthening effect, ensure the superheat of the molten pool, and good wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

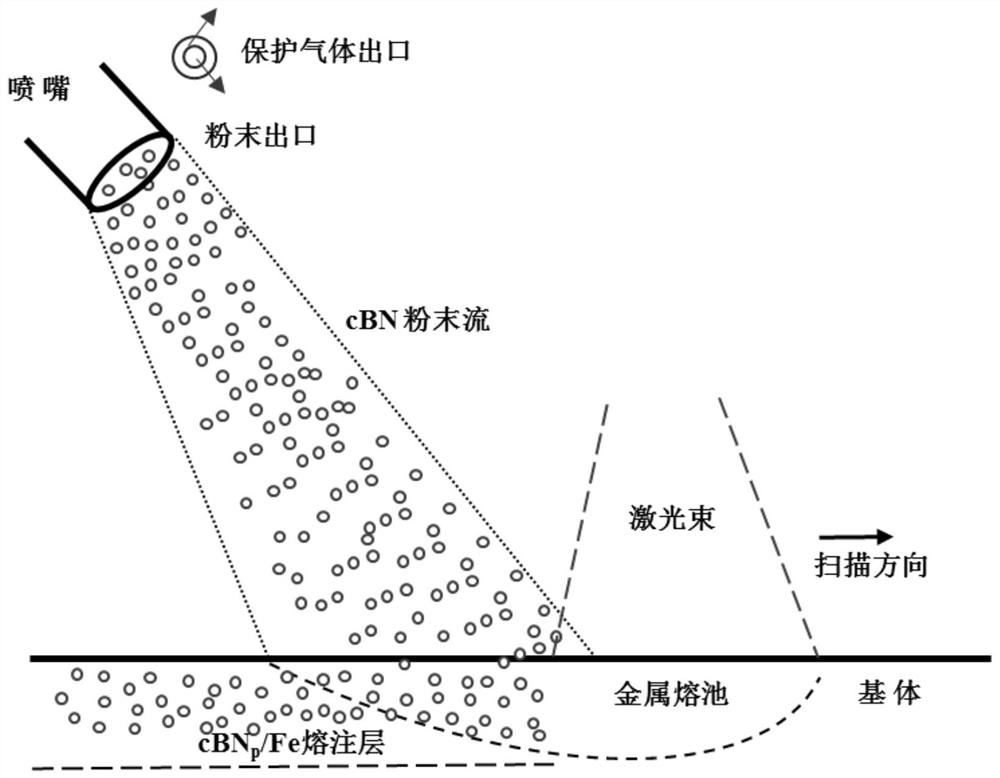

Method used

Image

Examples

Embodiment 1

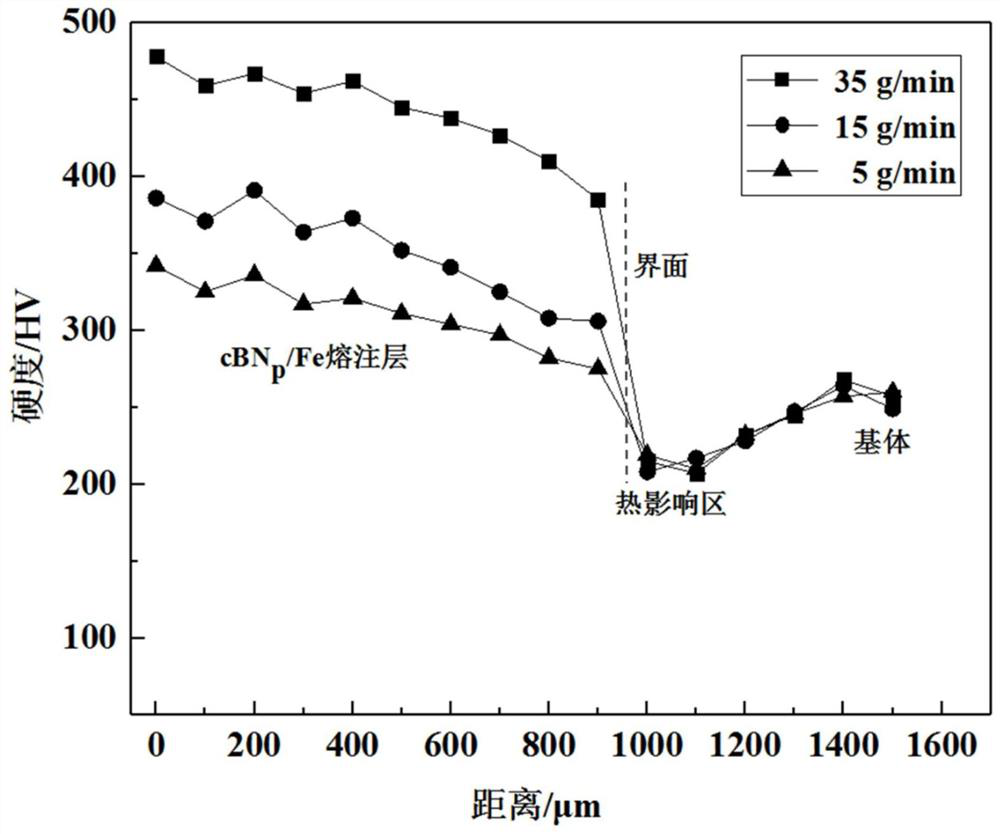

[0043] Select a forged 304 stainless steel plate and a sufficient amount of cBN ceramic particles to prepare the steel plate and ceramic particles before the experiment. By controlling the powder feeding speed, the volume fraction of the ceramic particles in the melting layer is adjusted, and the powder feeding rate is set at 35g / min. , to carry out synchronous paraxial powder feeding laser melting experiment.

[0044] S1 Place cBN ceramic particle powder material with a thickness of 45 μm to 150 μm in a drying oven, and dry it at 120° C. for 110 minutes to obtain dried cBN ceramic particles;

[0045] S2 Grind the surface of the 304 stainless steel plate to be strengthened with an angle grinder for 4 minutes, then perform ultrasonic cleaning at an ultrasonic frequency of 35 kHz for 8 minutes, and then dry the moisture on the surface of the 304 stainless steel plate with a drying oven , the drying time is 10min, and finally sandblasting is carried out to obtain the surface of t...

Embodiment 2

[0051] Select a forged 304 stainless steel plate and a sufficient amount of cBN ceramic particles to prepare the steel plate and ceramic particles before the experiment. By changing the powder feeding speed and changing the ceramic volume fraction of the melting layer, the powder feeding rate is set at 15g / min , to carry out synchronous paraxial powder feeding laser melting experiment.

[0052] S1: Place cBN ceramic particle powder material with a thickness of 45 μm to 150 μm in a drying oven, and dry at 100° C. for 120 minutes to obtain cBN ceramic particles after drying treatment.

[0053] S2: Grind the surface of the 304 stainless steel plate to be strengthened with an angle grinder for 10 minutes, then perform ultrasonic cleaning at an ultrasonic frequency of 35 kHz for 15 minutes, and then dry the surface of the 304 stainless steel plate with a drying oven Moisture, the drying time is 5min, and finally sandblasting is carried out to obtain the surface of the 304 stainless...

Embodiment 3

[0058] Select a forged 304 stainless steel plate and a sufficient amount of cBN ceramic particles to prepare the steel plate and ceramic particles before the experiment. By changing the powder feeding speed and changing the ceramic volume fraction of the melting layer, the powder feeding rate is set at 5g / min , to carry out synchronous paraxial powder feeding laser melting experiment.

[0059] S1: put cBN ceramic particle powder material with a thickness of 45 μm to 150 μm in a drying oven, and dry it at 150° C. for 90 minutes to obtain cBN ceramic particles after drying treatment;

[0060] S2: Grind the surface of the 304 stainless steel plate to be strengthened with an angle grinder for 1 minute, then perform ultrasonic cleaning at an ultrasonic frequency of 35 kHz for 5 minutes, and then dry the surface of the 304 stainless steel plate with a drying oven Moisture, the drying time is 15 minutes, and finally sandblasting is carried out to obtain the surface of the 304 stainle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spot diameter | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

| Microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com