A resin-based carbon fiber composite reinforced laminate and its preparation method

A composite material and carbon fiber technology, applied in the direction of synthetic resin layered products, chemical instruments and methods, lamination, etc., can solve the problems of delamination failure, reduce the bond strength of laminates, etc., to improve the tensile capacity and enhance the interlayer performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

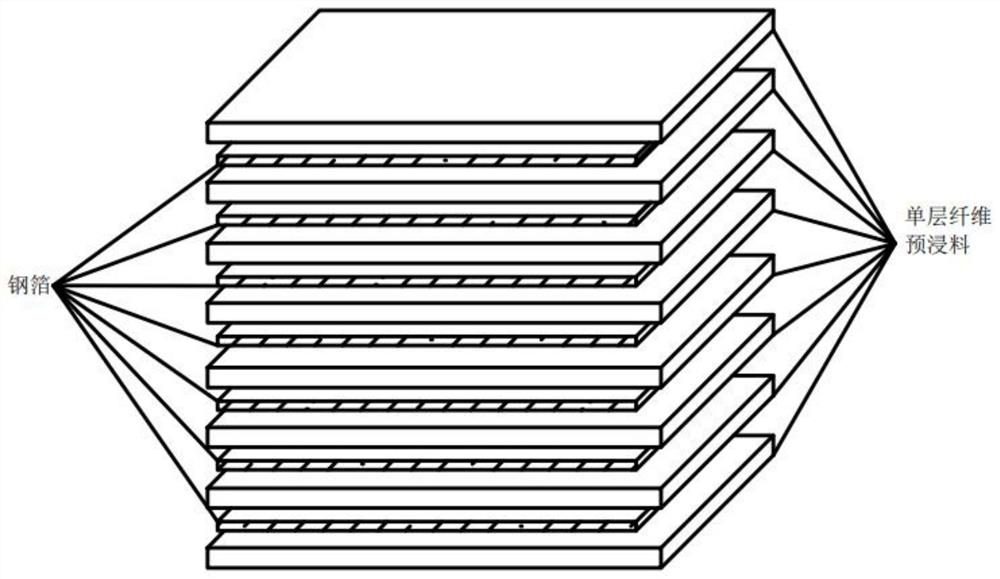

[0031] This embodiment provides a resin-based carbon fiber composite material reinforced laminate, wherein the resin-based carbon fiber composite material is a thermosetting composite material with epoxy resin as the matrix, and the raw material for the layup is carbon fiber / epoxy resin prepreg tape with a thickness of 0.1 mm, it cuts out prepreg tapes with different layup directions according to requirements. The steel foil is made of 304 stainless steel foil with a thickness of 0.02mm.

[0032] The specific process includes the following steps:

[0033] 1. Steel foil modification treatment: use acetone to wipe the surface of the steel foil, decontaminate and degrease, then put the cleaned steel foil into 100g / L sodium hydroxide solution for alkali washing for 30 minutes, clean and dry it and put it in Wash for 30 minutes twice in a solution prepared with 20mL ammonia water, 20mL hydrogen peroxide and 200mL water. Throughout the washing process, the temperature of the washi...

Embodiment 2

[0037] This embodiment provides a resin-based carbon fiber composite material reinforced laminate, wherein the resin-based carbon fiber composite material is a thermosetting composite material with epoxy resin as the matrix, and the raw material for the layup is carbon fiber / epoxy resin prepreg tape with a thickness of 0.1 mm, it cuts out prepreg tapes with different layup directions according to requirements. The steel foil is made of 304 stainless steel foil with a thickness of 0.01mm.

[0038] The specific process includes the following steps:

[0039] 1. Steel foil modification treatment: use acetone to wipe the surface of the steel foil, decontaminate and degrease, then put the cleaned steel foil into 90g / L sodium hydroxide solution for alkali washing for 35min, clean and dry it and put it in Carry out secondary washing for 25 minutes in a solution prepared by 20mL ammonia water, 20mL hydrogen peroxide and 180mL water. Throughout the washing process, the temperature of ...

Embodiment 3

[0043] This embodiment provides a resin-based carbon fiber composite material reinforced laminate, wherein the resin-based carbon fiber composite material is a thermosetting composite material with epoxy resin as the matrix, and the raw material for the layup is carbon fiber / epoxy resin prepreg tape with a thickness of 0.1 mm, it cuts out prepreg tapes with different layup directions according to requirements. The steel foil is made of 304 stainless steel foil with a thickness of 0.01mm.

[0044] The specific process includes the following steps:

[0045] 1. Steel foil modification treatment: use acetone to wipe the surface of the steel foil, decontaminate and degrease, then put the cleaned steel foil into 110g / L sodium hydroxide solution for alkali washing for 25 minutes, clean and dry it and put it in Carry out secondary washing for 25 minutes in a solution prepared by 20mL ammonia water, 20mL hydrogen peroxide and 200mL water. Throughout the washing process, the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com