Environment control and nitrogen production coupling system comprehensively utilizing aircraft cabin pressure and working method

A coupling system and working method technology, applied in aircraft parts, air handling equipment, transportation and packaging, etc., can solve problems such as safety hazards and waste of resources, and achieve high energy utilization, simple structure, high reliability and realizable sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the object, technical solution and effect of the present invention clearer and clearer, the following examples are given to further describe the present invention in detail. It should be pointed out that the specific implementations described here are only used to explain the present invention, not to limit the present invention.

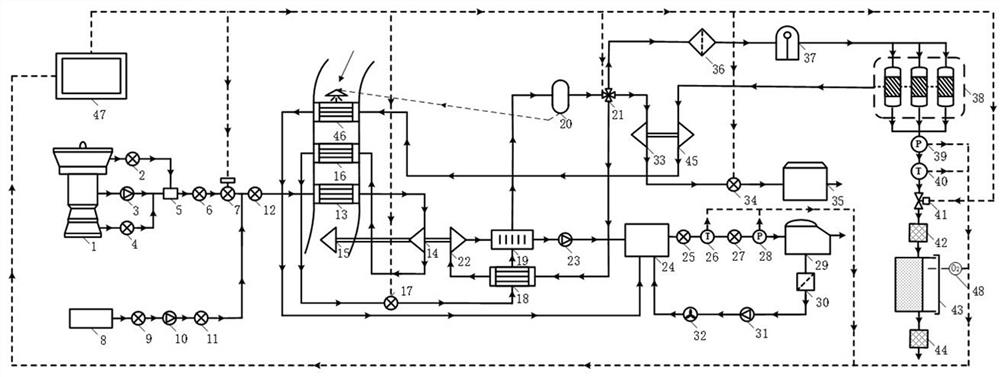

[0040] like figure 1 As shown, the present invention is a coupling system for environmental control and nitrogen control that comprehensively utilizes the pressure of the aircraft cabin, including an engine 1, a fan air conditioning valve 2, a first one-way valve 3, a high-pressure bleed air shut-off valve 4, and a precooler 5 , Shut-off valve 6, pressure regulator 7, auxiliary power unit 8, APU air supply shut-off valve 9, second one-way valve 10, isolation valve 11, flow control valve 12, first heat exchanger 13, first compressed air Machine 14, fan 15, second heat exchanger 16, first temperature control valve 17, regenera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com