Preparation method of stretchable hydrogel, stretchable hydrogel and application

A technology of hydrogel and bacterial cellulose, which is applied in the field of biomedical materials, can solve the problems of unsatisfactory coverage and fixation, and lack of antibacterial properties, and achieve good biocompatibility and biodegradability, good stretching and adhesion The effect of supplementary performance and great clinical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

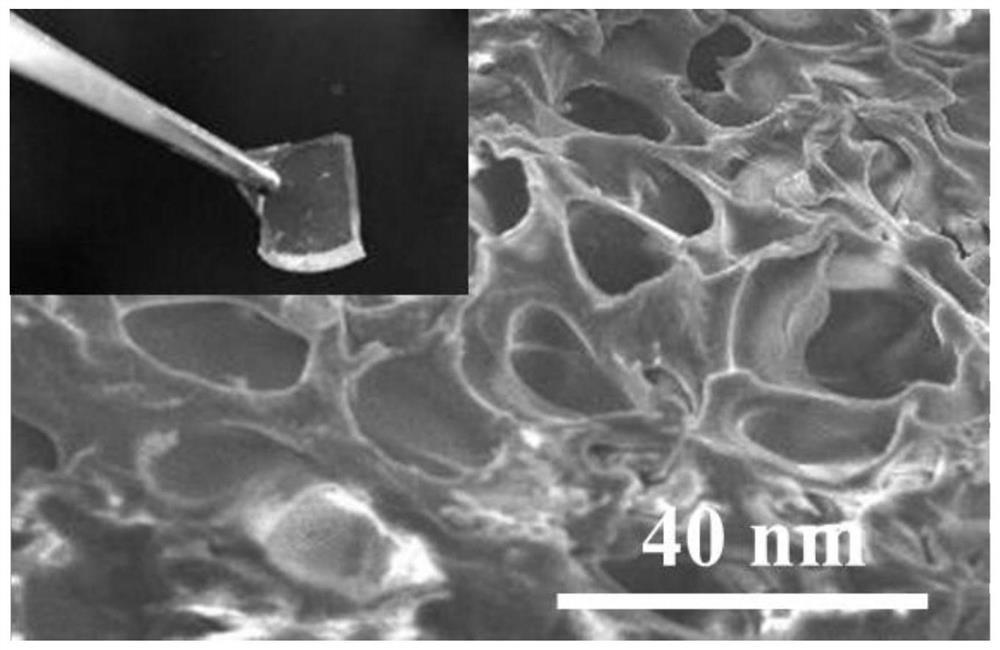

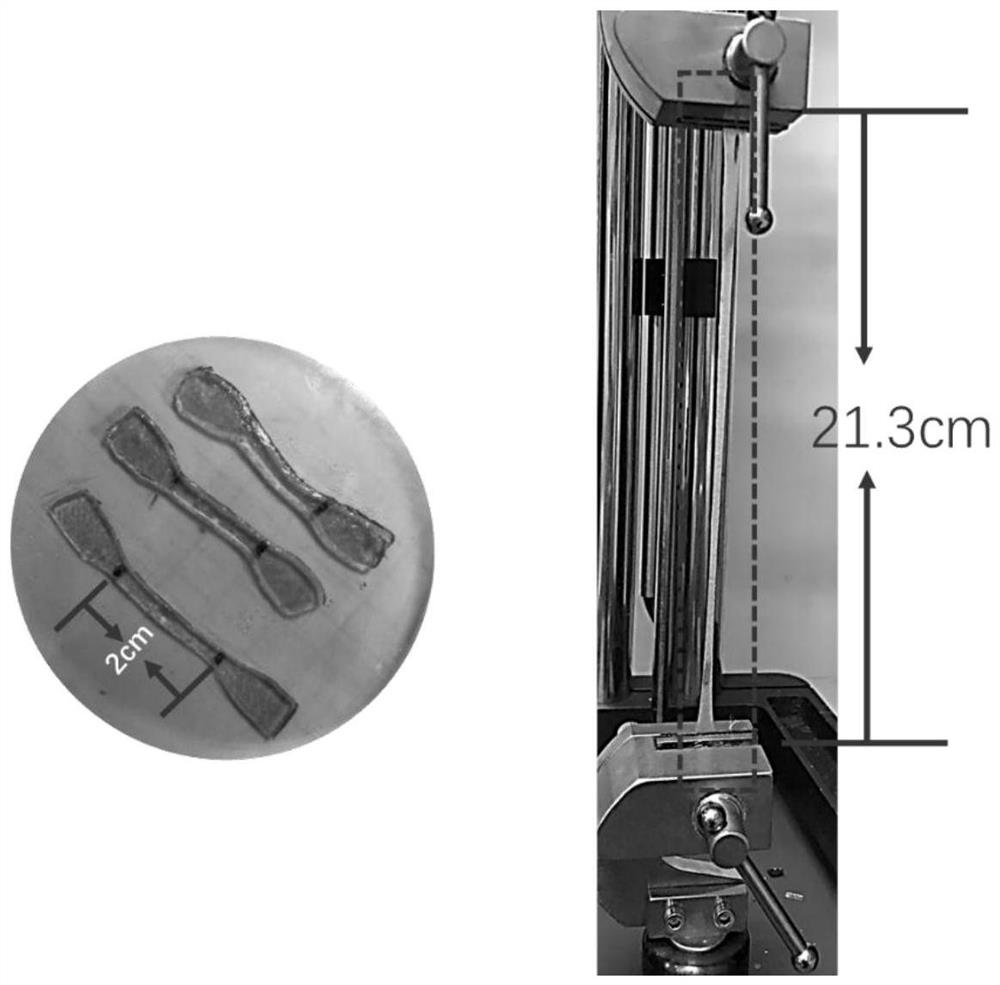

[0028] A kind of stretchable hydrogel, its preparation process is as follows:

[0029] S1. Take 4ml of 0.55-0.65%wt bacterial cellulose dispersion, add it to a centrifuge tube, and then dilute to 10ml with deionized water;

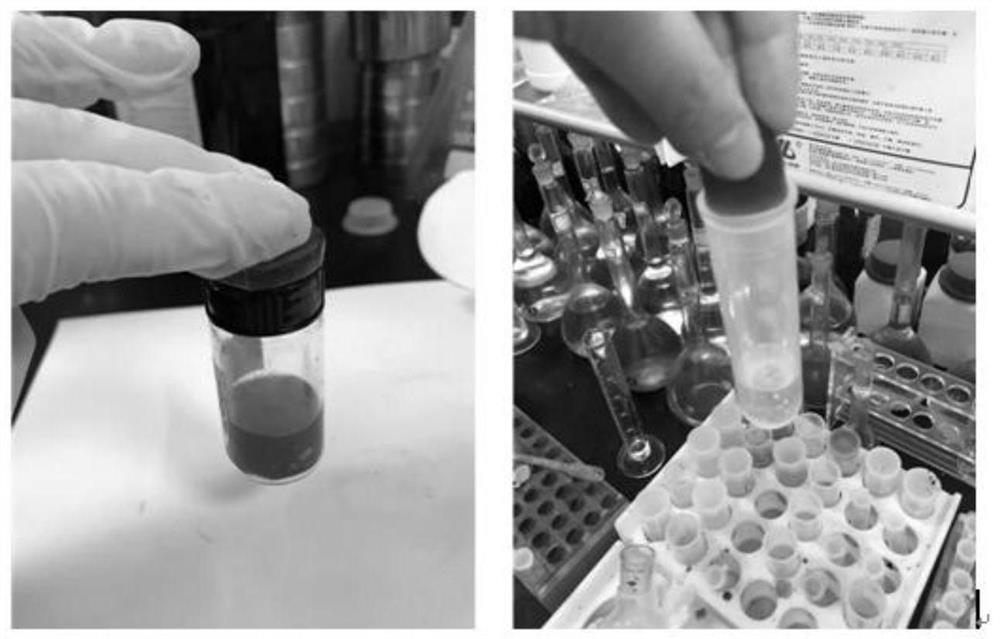

[0030] S2. Add 0.2 g of ammonium persulfate and 0.015 g of dopamine to the diluted bacterial cellulose dispersion obtained in step S1, stir at room temperature for about 30 min, and the mixture turns from white to brown;

[0031] S3. Add 2.5 g of acrylamide, 0.015 g of N,N-methylenebisacrylamide, and 20 μl of tetramethylethylenediamine to the system in step S2 under ice bath conditions, and stir for 10 min. After returning to room temperature, the mixture is The brown color becomes brownish red, and then the mixture is poured into a petri dish, and placed in a 60°C incubator for 2-3 hours, or placed at room temperature for 48 hours, to obtain a stretchable hydrogel.

Embodiment 2

[0033] A kind of stretchable hydrogel, its preparation process is as follows:

[0034] S1. Take 4ml of 0.55-0.65%wt bacterial cellulose dispersion, add it to a centrifuge tube, and then dilute to 10ml with deionized water;

[0035] S2. Add 0.2 g of ammonium persulfate and 0.01 g of dopamine to the diluted bacterial cellulose dispersion obtained in step S1, stir at room temperature for about 30 min, and the mixture turns from white to brown;

[0036] S3. Add 2 g of acrylamide, 0.015 g of N,N-methylenebisacrylamide, and 10 μl of tetramethylethylenediamine to the system in step S2 under ice bath conditions, and stir for 10 min. After returning to room temperature, the mixture turns from brown to It turns brownish red, and then the mixture is poured into a petri dish, and placed in a 60°C incubator for 2-3 hours, or placed at room temperature for 48 hours, to obtain a stretchable hydrogel.

Embodiment 3

[0038] A kind of stretchable hydrogel, its preparation process is as follows:

[0039] S1. Take 4ml of 0.55-0.65%wt bacterial cellulose dispersion, add it to a centrifuge tube, and then dilute to 10ml with deionized water;

[0040] S2. Add 0.2 g of ammonium persulfate and 0.02 g of dopamine to the diluted bacterial cellulose dispersion obtained in step S1, stir at room temperature for about 30 min, and the mixture turns from white to brown;

[0041]S3. Continue to add 3g of acrylamide, 0.015g of N,N-methylenebisacrylamide, and 30μl of tetramethylethylenediamine to the system in step S2 under ice bath conditions, and stir for 10min. After returning to room temperature, the mixture turns from brown to It turns brownish red, and then the mixture is poured into a petri dish, and placed in a 60°C incubator for 2-3 hours, or placed at room temperature for 48 hours, to obtain a stretchable hydrogel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com