Silicon micro-pillar array three-electrode ionization microsystem haze sensor and preparation method

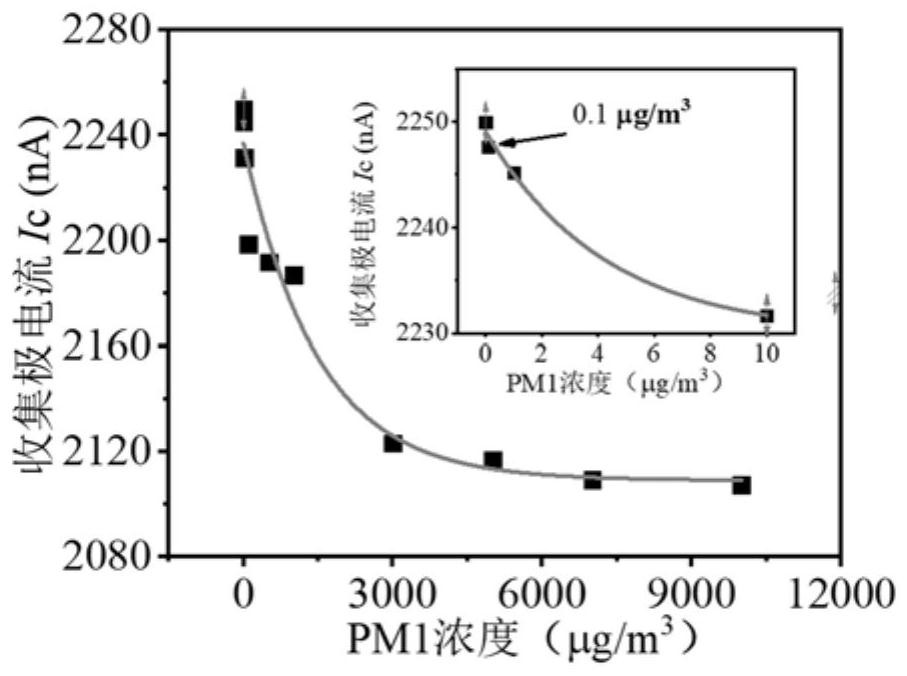

A micro-column and sensor technology, which is applied in the fields of instruments, scientific instruments, suspensions and porous materials analysis, etc., can solve the problems of not seeing the sensor, etc., and achieve the effect of large collector current, high resolution and small work function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The preparation method of the three-electrode ionization microsystem haze sensor of silicon micro-pillar array comprises the following steps:

[0048] 1) Pretreatment before deep silicon etching: Three electrode silicon wafers etched with small through holes, lead-out holes and deep grooves are selected as the substrate, and pretreatment of deep silicon etching is carried out before cleaning, gluing, and exposure;

[0049] 2) Silicon micro-pillar array etching: The sensor silicon micro-pillar array is prepared by the deep reactive ion etching DRIE method based on the alternating reciprocating Bosch process; in the Bosch process, the two steps of etching and passivation will be alternated until Reach the etching depth requirement.

[0050] In continuous access to SF 6 protective gas, C 4 F 8 Under the condition of etching gas for 2 to 15s, set the pressure to 6Pa, the radio frequency power to 20 to 70W, the source power to 220 to 450W, C 4 F 8 with SF 6 The gas flo...

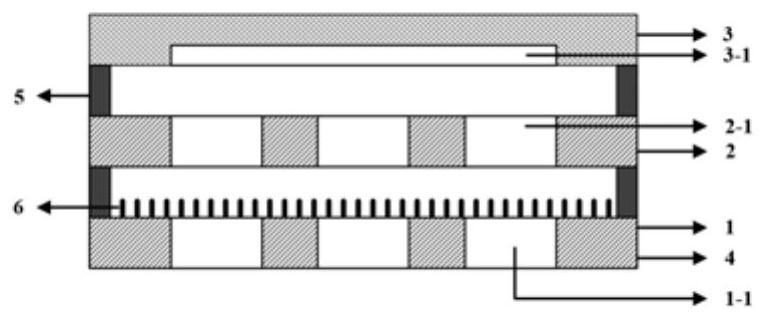

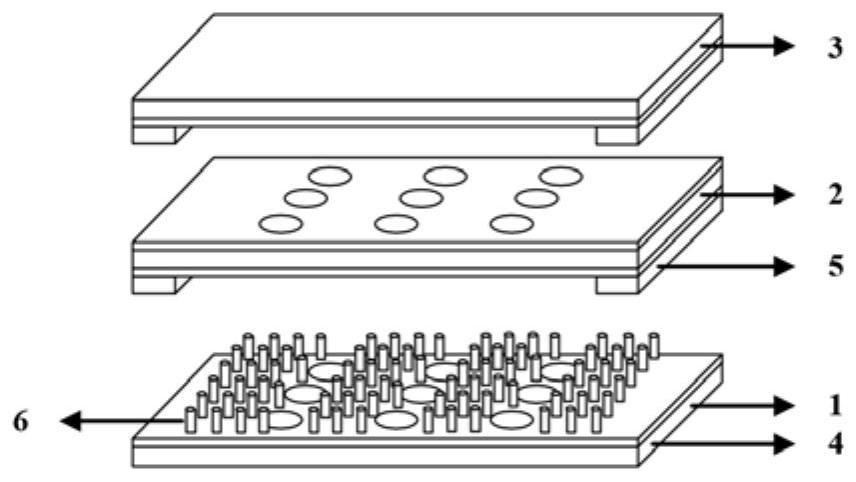

Embodiment 1

[0057] There are 2 small through holes 1-1 on the electrode of the first electrode, the hole diameter is set at 3mm, and the ratio of the distance between the first electrode and the second electrode to the small through hole is 3 / 32; 9 small lead-out holes, the diameter of the small lead-out hole is 1.2mm, and the ratio between the pole spacing between the first electrode and the second electrode, between the second electrode and the third electrode and the diameter of the small lead-out hole is 1 / 16; There is a deep groove on the electrode, the side length of the deep groove is 6×8 mm, the depth is 200 μm, and the ratio of the electrode spacing between the second electrode and the third electrode to the hole depth of the collector deep groove is 15 / 40. The inner surface of the first electrode is prepared with a silicon micro-pillar array structure with an interval of 10 μm, a diameter of 8 μm and a height of 40 μm.

[0058] The preparation steps of the silicon micro-pillar a...

Embodiment 2

[0070] The basic structure of this embodiment is the same as that of Embodiment 1, the difference is that there are 16 small through holes on the electrode of the first electrode, the diameter of which is set at 3.6mm, the distance between the first electrode and the second electrode and the small through holes The ratio of the aperture is 1 / 60; the second electrode has 16 small extraction holes from the center, the aperture of the small extraction hole is 5.0mm, and the ratio of the electrode spacing between the first electrode and the second electrode to the aperture of the small extraction hole is 3 / 250; the ratio of the electrode spacing between the second electrode and the third electrode to the diameter of the small lead-out hole is 9 / 1000; the third electrode is provided with 12 deep grooves, the side length of the deep groove is 1.0×1.0mm, and the depth is 100μm, The ratio between the electrode spacing between the second electrode and the third electrode and the groove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com