Mask blank and photomask

A technology of mask blanks and photomasks, applied in optics, originals for photomechanical processing, ion implantation plating, etc., can solve the problem of poor etching rate between the light-shielding layer and the anti-reflection layer, non-progressive etching of the anti-reflection layer, Problems such as low etch rate of anti-reflection layer etch rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

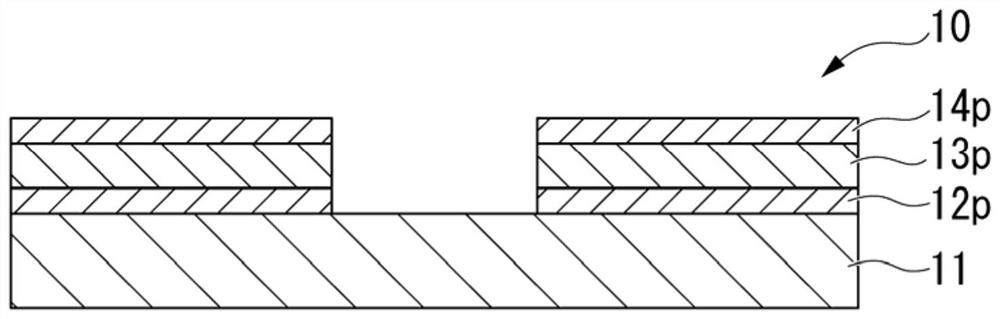

[0169] A film of a chromium compound as a three-layer mask layer was formed on a glass substrate using a sputtering method.

[0170] When forming the chromium compound film as the light-shielding layer, sputtering is performed with nitrogen gas.

[0171] Nitrogen gas was used to sputter when forming the chromium compound film as the upper and lower antireflection layers. In addition, as the oxidizing gas, choose CO 2 gas and NO gas, and change the partial pressure of each gas. Show its gas ratio in figure 1 .

[0172] [Table 1]

[0173]

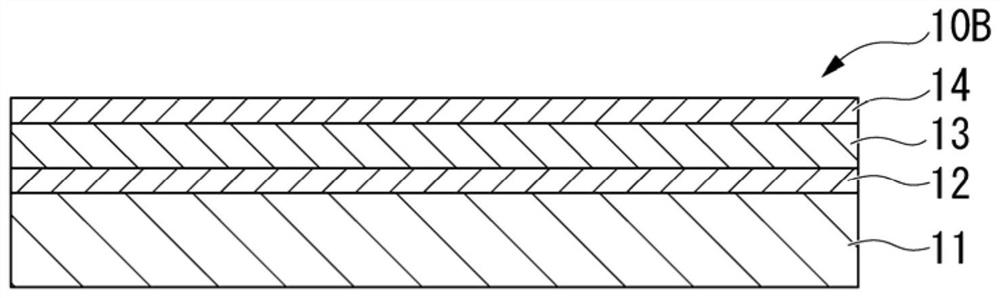

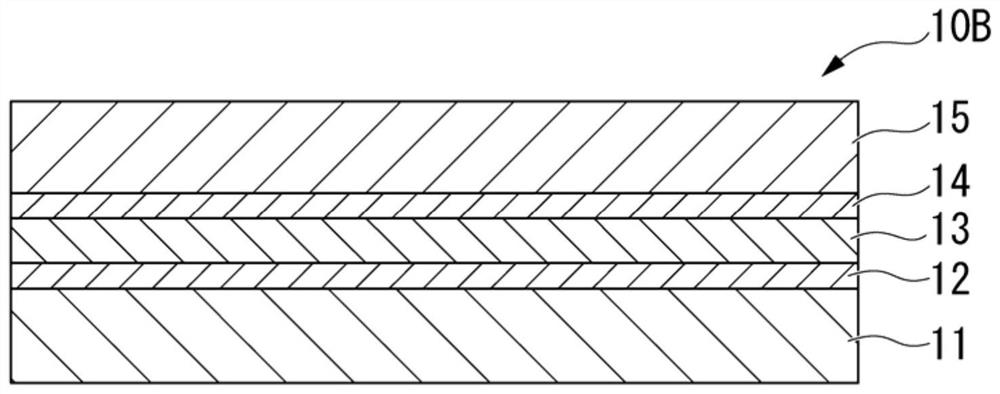

[0174] In addition, Table 2 shows the film thickness of the lower antireflection layer 12 , the film thickness of the light shielding layer 13 , the film thickness of the upper antireflection layer 14 , and the total film thickness of the mask layer.

[0175] [Table 2]

[0176]

[0177] Changes in the composition ratios of N, O, Cr, and C in each layer of Example 1 were determined by Auger electron spectroscopy. The results are s...

Embodiment 2

[0188] A film of a chromium compound as a three-layer mask layer was formed on a glass substrate using a sputtering method.

[0189] When forming the chromium compound film as the light-shielding layer, sputtering is performed with nitrogen gas.

[0190] Nitrogen gas was used to sputter when forming the chromium compound film as the upper and lower antireflection layers. In addition, as the oxidizing gas, choose CO 2 gas and NO gas, and change the partial pressure of each gas. The gas ratio is shown in Table 1.

[0191] In addition, Table 2 shows the film thickness of the lower antireflection layer 12 , the film thickness of the light shielding layer 13 , the film thickness of the upper antireflection layer 14 , and the total film thickness of the mask layer.

[0192] Changes in the composition ratios of N, O, Cr, and C in each layer of Example 2 were determined by Auger electron spectroscopy. The results are shown in Table 6.

[0193] [Table 6]

[0194]

[0195] In a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com