Microbial fuel cell constructed by Fe-MOF-GO film anode

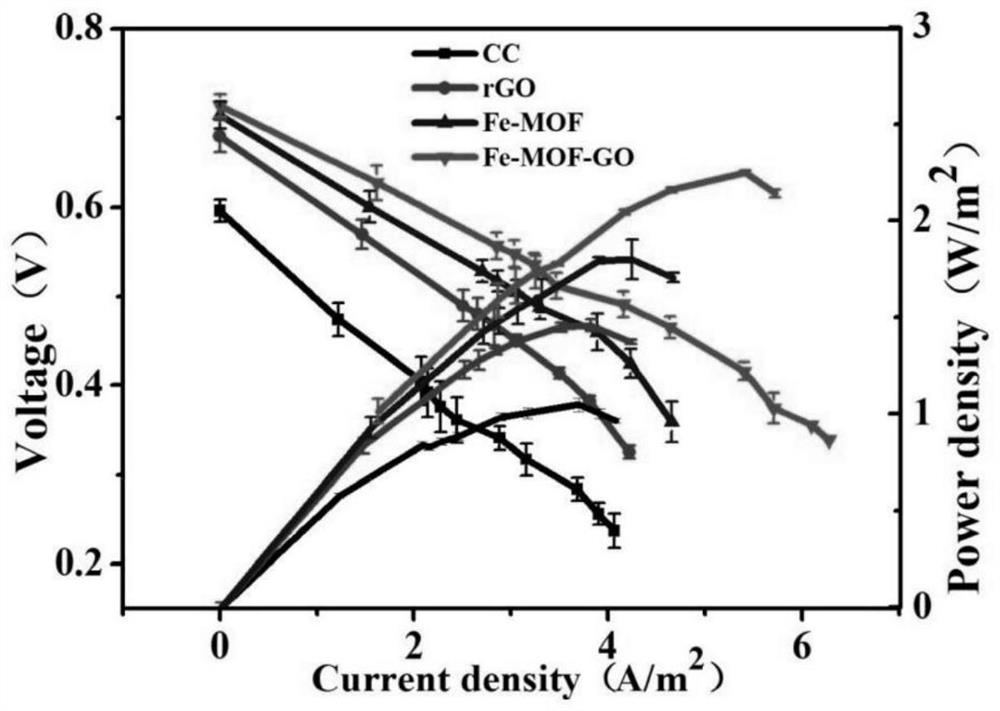

A fuel cell and microorganism technology, applied in biochemical fuel cells, battery electrodes, biological water/sewage treatment, etc., can solve the problems of high potential, short cycle and low power of microbial fuel cells, achieve good biocompatibility, promote The effect of connection and enrichment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the Fe-MOF-GO film that is used for microbial fuel cell in the present embodiment is carried out according to the following steps:

[0033] Step 1, the preparation of Fe-MOF nanoparticle: in the beaker of 50mL, add the water of 20ml, add 0.35g iron trichloride (FeCl 3 ) and 5.05g diaminoterephthalic acid (C 8 h 7 NO 4 ), transfer the mixed solution into a reaction kettle, react at 100-260° C. for 15 hours, centrifuge at a speed of 10,000 r / min, and pour off the supernatant. The precipitate was washed three times by centrifugation with distilled water, once by ethanol, and dried in vacuum at 60°C for 12 hours to obtain yellow Fe-MOF nanoparticles;

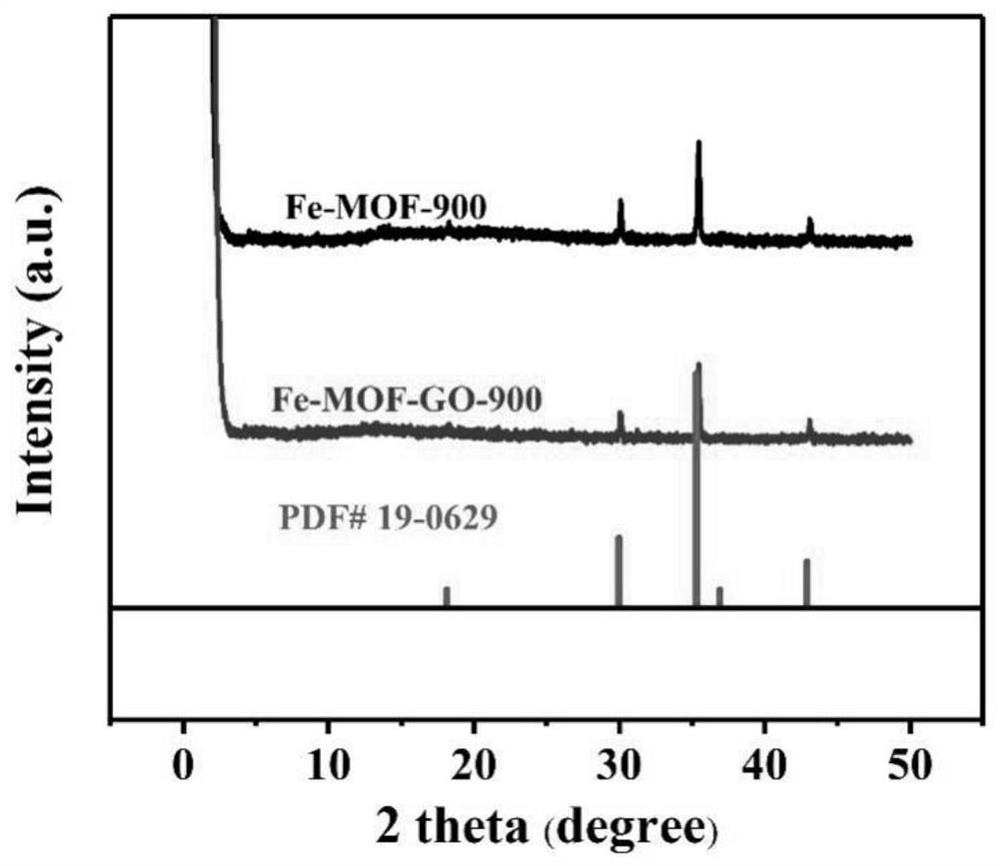

[0034]Step 2. Put the yellow Fe-MOF nanoparticles into the tube furnace to evacuate and then pass in nitrogen gas, raise the temperature from 20°C to 900°C at a rate of 5°C / min, keep the temperature at 900°C for 6 hours, / min rate to cool down to room temperature to obtain Fe-MOF;

[0035] Step ...

Embodiment 2

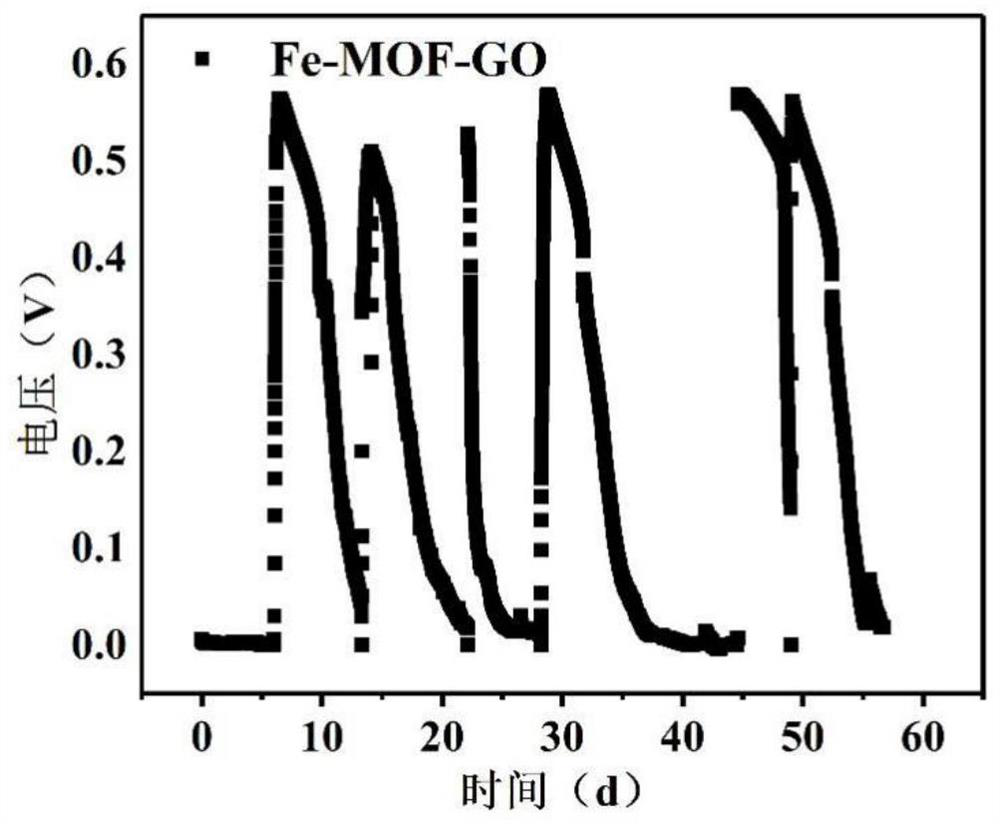

[0038] Implementation 2: Microbial fuel cells (MFCs) constructed using the Fe-MOF-GO thin film prepared by the preparation method described in Example 1:

[0039] 1. Pretreatment of required materials:

[0040] Pretreatment of carbon brushes: Put 10 carbon brushes with the carbon cloth fiber side down into a 500mL beaker, then add 450mL of acetone, soak for 30min, take it out, put it directly into a tube furnace, and burn it at 350°C After 30 minutes, cool down to room temperature naturally, take it out and put it in a 500mL beaker, seal it with parafilm, and set it aside.

[0041] Pretreatment method of Nafion membrane: 10×10cm 2 The Nafion membrane is divided into 9 parts on average, and the cut Nafion membrane is put into a 100mL beaker. In order to remove organic impurities, add 100mL3% H to the beaker 2 o 2 , placed in an oven, treated at 80°C for 30 minutes; put 100mL of 3% H 2 o 2 Pour it out, add 100mL of distilled water, put it in an oven, and treat it at 80°C fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com