Preparation method of co-mof-go thin film for microbial fuel cell and its constructed MFCs

A fuel cell, microbial technology, applied in MFCs. It can solve problems such as reducing electrical conductivity, achieve good biocompatibility, promote contact, and improve MFC power yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the Co-MOF-GO film that is used for microbial fuel cell in the present embodiment is carried out according to the following steps:

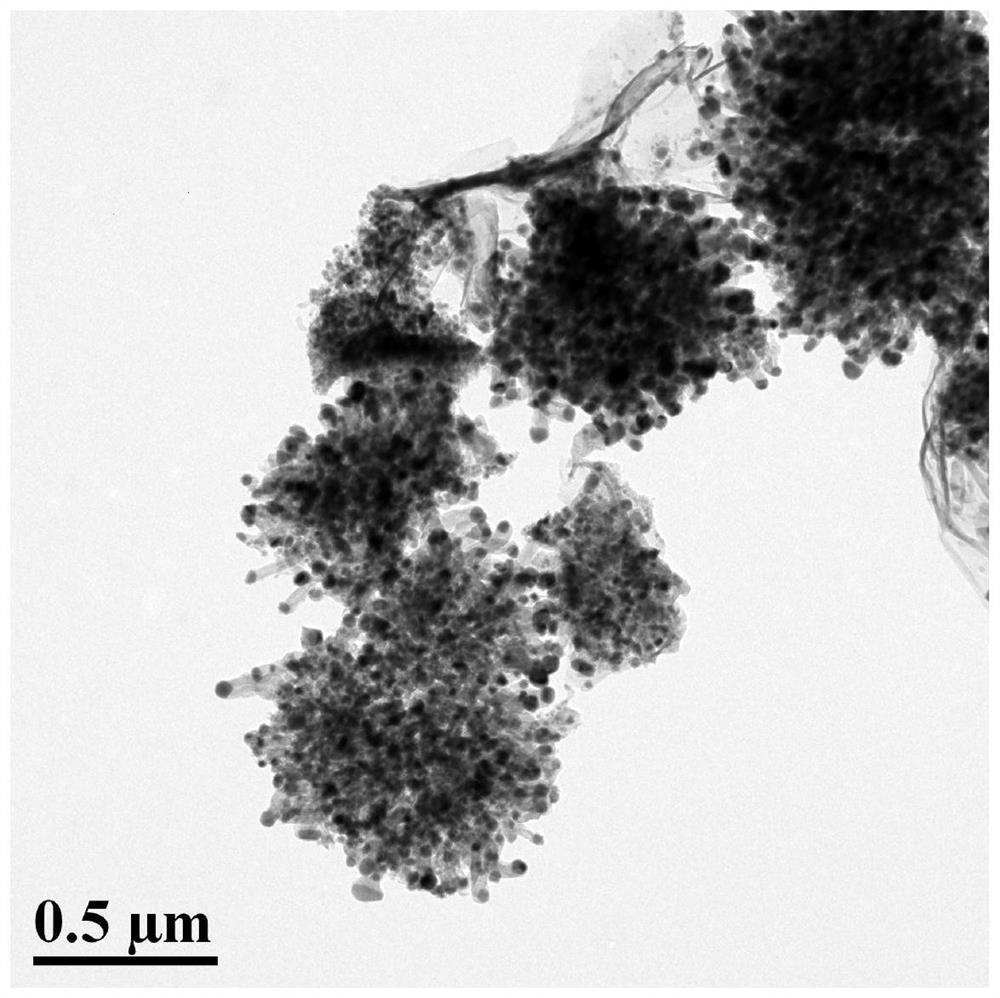

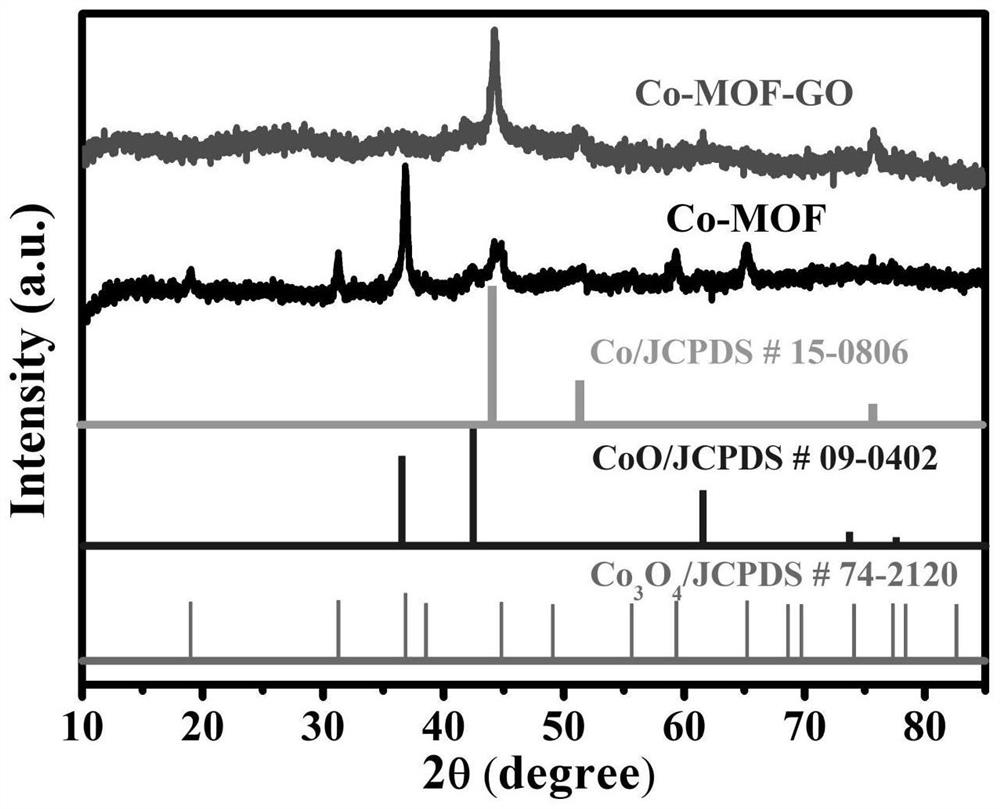

[0035] Step 1. Preparation of Co-MOF-GO nanoparticles: In a 50mL beaker, add 20ml of 2mg / ml GO aqueous solution, and add 0.35g of cobalt nitrate hexahydrate (Co(NO 3 )2 ·6H 2 O) and 5.05g dimethylimidazole (C4H6N2), under the condition of 300-600r / min speed magnetic stirring reaction for 3 hours, obtain the purple black solution, carry out centrifugation with 10000r / min speed, solid water centrifugation cleaning three times, then ethanol Centrifugal cleaning once, vacuum drying to obtain purple-black Co-MOF-GO nanoparticles;

[0036] Step 2. After vacuuming, nitrogen gas is introduced, and the temperature is raised from 20°C to 550°C at a rate of 5°C / min. The temperature is maintained at 550°C for 6 hours, and the temperature is lowered to room temperature at a rate of 5°C / min. Co- MOF-GO composite;

[0037] St...

Embodiment 2

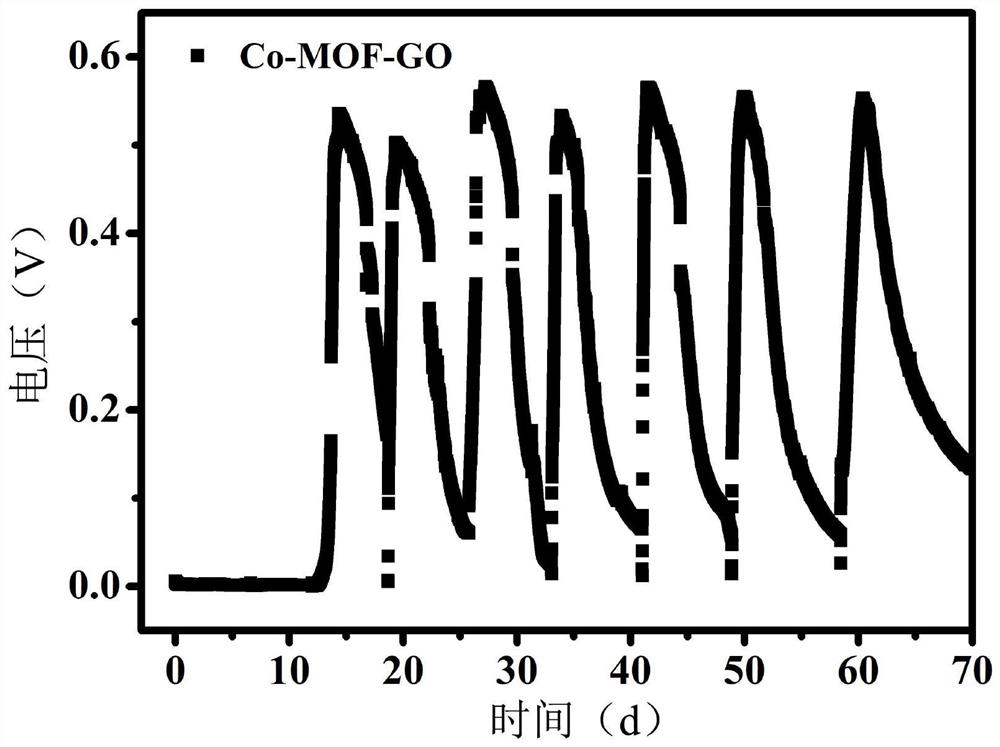

[0039] Embodiment 2: The microbial fuel cell (MFCs) that adopts the Co-MOF-GO thin film construction that the preparation method described in Example 1 makes:

[0040] 1. Pretreatment of required materials:

[0041] Carbon brush pretreatment method: Put 10 carbon brushes with the carbon cloth fiber side down into a 0.5L beaker, then add 0.45L acetone, soak for 30min, take it out, put it directly into a large tube furnace, and then Sinter at 350°C for 30 minutes, cool down to room temperature naturally, take it out and put it in a 0.5L beaker, seal it with a parafilm, and set it aside.

[0042] Pretreatment method of Nafion membrane: 10×10cm 2 Divide the Nafion membrane into 9 parts on average, put the cut Nafion membrane into a 100mL beaker, add 100mL3% H 2 o 2 , placed in an oven, treated at 80°C for 30 minutes to remove organic impurities; put 100mL of 3% H 2 o 2 Pour it out, add 100mL of distilled water, put it in an oven, and treat it at 80°C for 30min; then pour out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com