Coarse cereal milk and preparation method thereof

A technology of miscellaneous grains and miscellaneous grain powder, which is applied in the field of miscellaneous grain milk and its preparation, can solve the problems of increasing energy consumption, manpower and other costs, prolonging ingredients, production time, and inability to realize one-time feeding, so as to save gelatinization time, shorten The effect of reducing production time and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

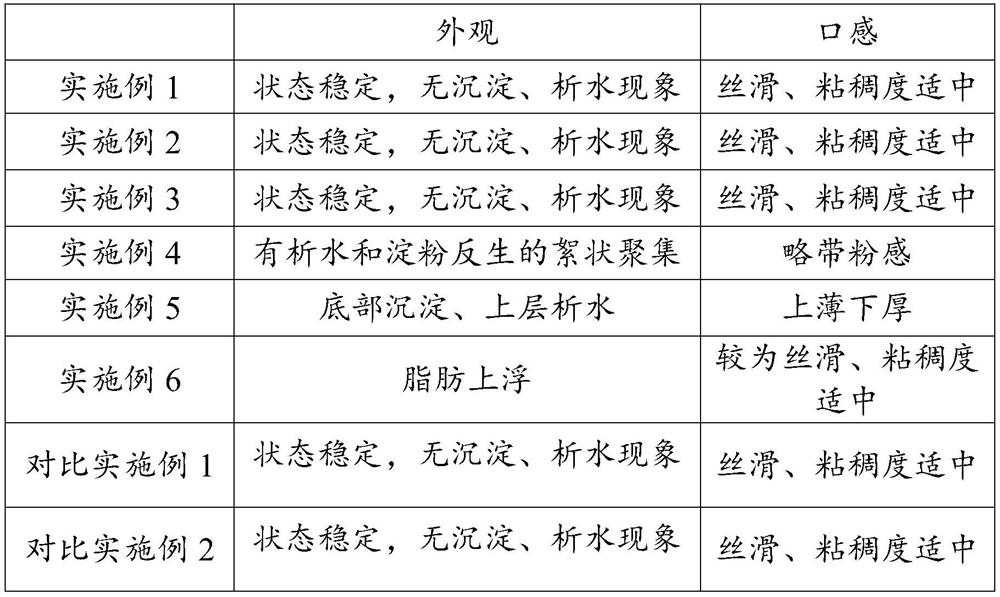

Examples

Embodiment 1

[0041] A method for preparing multigrain milk, comprising the following steps:

[0042] (1) Mix the ingredients, preheat the batching tank to 70°C, put miscellaneous grain powder, gellan gum, carrageenan, mono- and diglycerin fatty acid esters, sucrose fatty acid esters, white granulated sugar and water into the batching tank and mix to obtain Miscellaneous grain liquid, wherein water: miscellaneous grain powder = 12:1;

[0043] (2) Gelatinization, when the tube-and-tube heat exchanger is preheated to 75°C, inject the miscellaneous grain liquid obtained in step (1) into the tube-and-tube heat exchanger for heating, and the miscellaneous grain liquid flows through the tube-and-tube heat exchanger The time of the machine is 15min, and the miscellaneous grain slurry is obtained, wherein the diameter of the shell and tube heat exchanger is 20mm;

[0044] (3) once homogeneous, the multigrain slurry obtained in step (2) is homogenized through a colloid mill;

[0045] (4) cooling, ...

Embodiment 2

[0052] A preparation method of brown rice milk, comprising the following steps:

[0053] (1) Mixing, the preheating batching tank is 70 ℃, brown rice flour, carrageenan, mono- and diglyceride fatty acid esters, white granulated sugar and water are put into the batching tank and mixed to obtain brown rice liquid, wherein water: brown rice flour= 8:1;

[0054] (2) Gelatinization, when the coil heat exchanger is preheated to 75°C, inject the brown rice liquid obtained in step (1) into the coil heat exchanger for heating, and the brown rice liquid flows through the coil heat exchanger The time of the device is 15min to obtain brown rice slurry, wherein the diameter of the coil heat exchanger is 10mm;

[0055] (3) once homogeneous, the brown rice pulp gained in step (2) is homogenized through a colloid mill;

[0056] (4) cooling, the brown rice milk obtained in step (3) is cooled at 4° C. to obtain brown rice milk;

[0057] (5) constant volume, the brown rice milk obtained in st...

Embodiment 3

[0062] A method for preparing multigrain milk, comprising the following steps:

[0063] (1) Mix the ingredients, preheat the batching tank to 70°C, put brown rice powder, red bean powder, black sesame powder, gellan gum, mono- and diglycerin fatty acid esters, sucrose fatty acid esters, white sugar and water into the batching tank Internally mixed to obtain miscellaneous grains liquid, wherein water: miscellaneous grains powder (brown rice flour, red bean powder, black sesame powder)=10:1;

[0064] (2) Gelatinization, when the tube-and-tube heat exchanger is preheated to 75°C, inject the miscellaneous grain liquid obtained in step (1) into the tube-and-tube heat exchanger for heating, and the miscellaneous grain liquid flows through the tube-and-tube heat exchanger The time of the device is 15min, and the miscellaneous grain slurry is obtained, wherein the diameter of the shell and tube heat exchanger is 20mm;

[0065] (3) once homogeneous, the multigrain slurry obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com