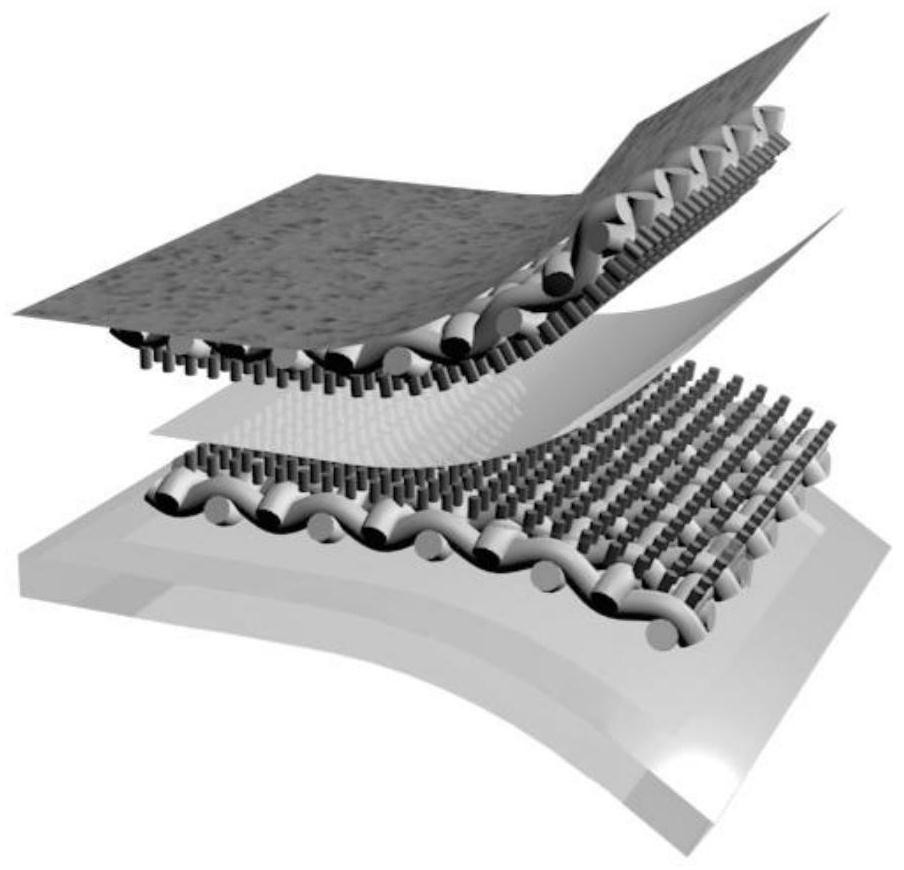

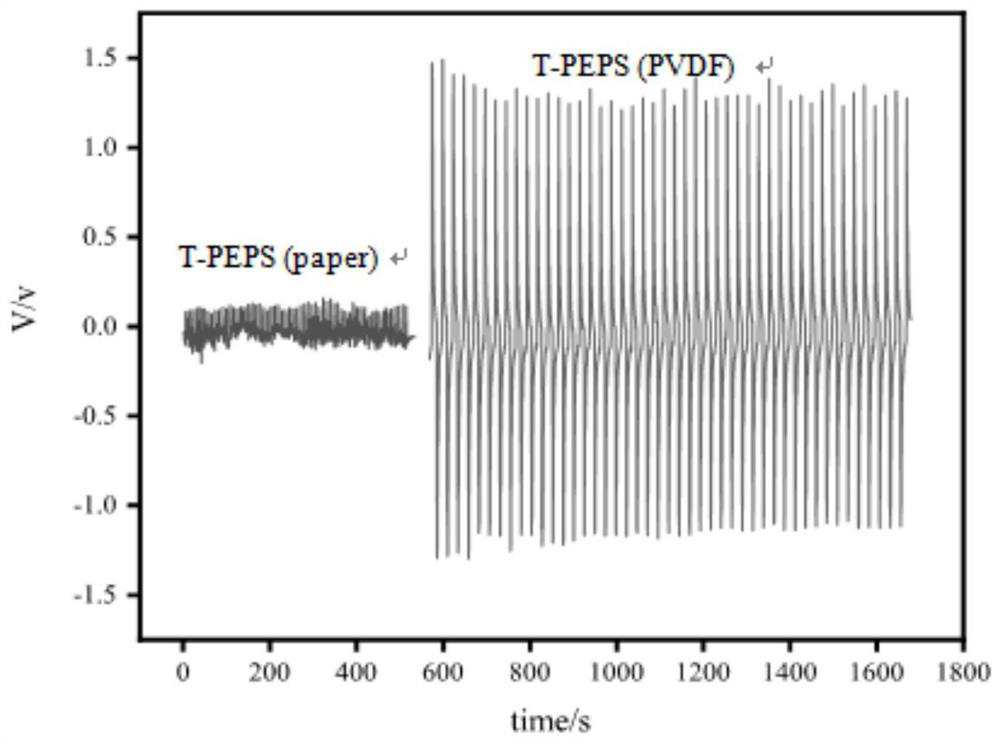

Fabric substrate piezoelectric sensor based on zinc oxide nanorod structures and preparation method of fabric substrate piezoelectric sensor

A technology of zinc oxide nanorods and piezoelectric sensors, applied in chemical instruments and methods, sensors, nanotechnology for sensing, etc., can solve the problems of low sensitivity, complicated preparation process, and low recognition, and achieve high sensitivity , excellent gas permeability, low monitoring limit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

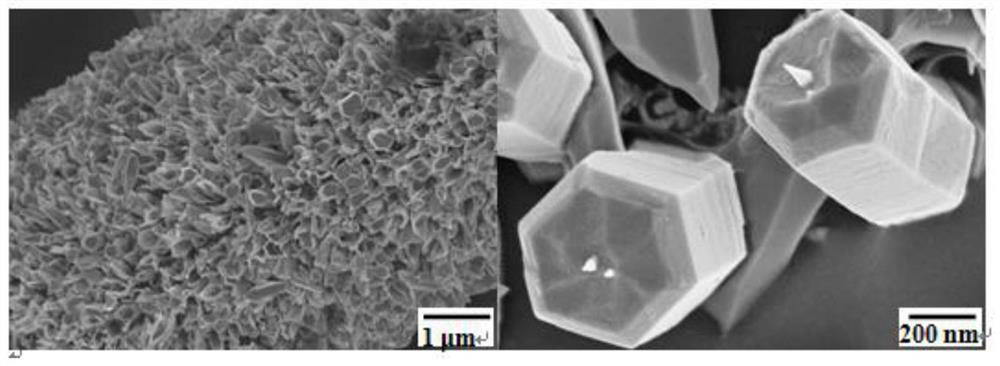

Embodiment 1

[0028] 1. Preparation of highly conductive textile electrodes

[0029]Perform plasma treatment on the surface of the polyester fabric, the treatment atmosphere is oxygen, the treatment power is 400w, and the treatment time is 120s, then take 100mL deionized water, add 0.5g stannous chloride and 0.1mL hydrochloric acid with a mass concentration of 30%, respectively, A mixed solution containing stannous chloride and hydrochloric acid was prepared, and the treated polyester fabric was immersed in the mixed solution for 2 hours at a temperature of 80°C; then 0.3g of graphene oxide powder was ultrasonically treated and dispersed in 100mL of Prepare a 3 mg / mL graphene oxide solution in deionized water for 30 minutes, rinse with deionized water to remove impurities, and continue to immerse the polyester fabric in the graphene oxide solution at a temperature of 25°C for 0.25 hours. After repeated immersion for 3 times drying; finally, the dried polyester fabric was reduced with 5 g / L ...

Embodiment 2

[0037] 1. Preparation of highly conductive textile electrodes

[0038] Perform plasma treatment on the surface of polyester fabric, the treatment atmosphere is oxygen, the treatment power is 400w, and the treatment time is 120s, then take 100mL deionized water, add 1g stannous chloride and 0.2mL hydrochloric acid with a mass concentration of 32% respectively, and prepare A mixed solution containing stannous chloride and hydrochloric acid was obtained, and the treated polyester fabric was immersed in the mixed solution for 1h at a temperature of 70°C; then 0.2g of graphene oxide powder was ultrasonically treated and dispersed in 100mL of Prepare a 2 mg / mL graphene oxide solution in deionized water for 30 minutes, rinse with deionized water to remove impurities, continue to immerse the polyester fabric in the graphene oxide solution, immerse at a temperature of 20 °C for 0.35 h, repeat the immersion 5 times, and then bake Drying; finally, the dried polyester fabric was reduced w...

Embodiment 3

[0046] 1. Preparation of highly conductive textile electrodes

[0047] Perform plasma treatment on the surface of the polyester fabric, the treatment atmosphere is oxygen, the treatment power is 400w, and the treatment time is 120s, then take 100mL deionized water, add 1.5g stannous chloride and 0.3mL hydrochloric acid with a mass concentration of 36%, respectively, A mixed solution containing stannous chloride and hydrochloric acid was prepared, and the treated polyester fabric was immersed in the mixed solution for 3 hours at a temperature of 90°C; then 0.5g of graphene oxide powder was ultrasonically treated and dispersed in 100mL of Prepare a 5 mg / mL graphene oxide solution in deionized water for 30 minutes, rinse with deionized water to remove impurities, and continue to immerse the polyester fabric in the graphene oxide solution at a temperature of 30°C for 0.4 hours, and repeat the immersion 3 times drying; finally, the dried polyester fabric was reduced with 10 g / L L-a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com