Method for high-temperature melting treatment of chemical waste salt

A high-temperature melting and molten salt technology, which is applied in the purification of alkali metal chlorides, alkali metal halides, crucible furnaces, etc., can solve the problems of incomplete treatment of organic matter and the inability to obtain industrial salt that meets the national standard, and achieves enhanced removal and accelerated reaction. Reasonable effect of speed and process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1 A kind of method of high-temperature fusion oxidation process chemical industry waste salt

[0040]A method for treating chemical waste salt by high-temperature fusion oxidation method of the present invention comprises the following steps:

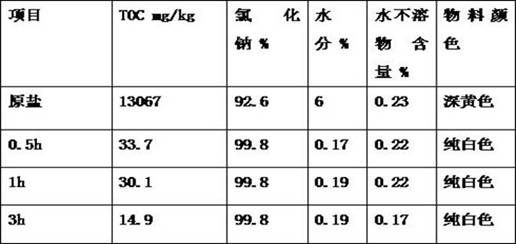

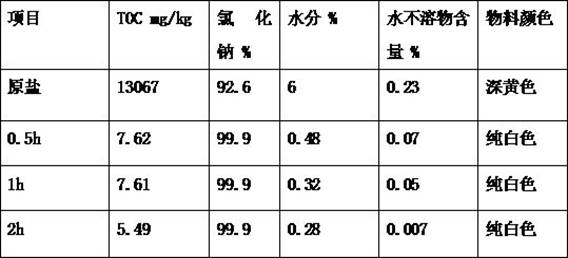

[0041] (1) The basic parameters of pesticide waste salt are: TOC content 13067mg / kg, moisture content 6%, water insoluble content 0.23%, the main pollutants are pesticides, containing tar substances.

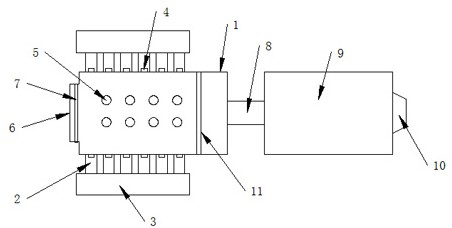

[0042] 2) Take 709g of chemical waste salt and add it to the high-temperature melting oxidation furnace. The high-temperature melting oxidation furnace in this embodiment takes a horizontal flame furnace as an example, as figure 1 As shown, it includes a melting tank cavity 1, and burners for heating the inner cavity are installed on both sides of the melting tank cavity 1 alternately, and a regenerator 3 is also connected to the burner. The melting tank cavity 1 is provided with a discharge channel 8 whose height is eq...

Embodiment 2

[0048] Embodiment 2 A kind of method of high-temperature melting oxidation process chemical industry waste salt

[0049] A method for treating chemical waste salt by high-temperature fusion oxidation method of the present invention comprises the following steps:

[0050] (1) The basic parameters of pesticide waste salt are: TOC content 13067mg / kg, moisture content 6%, water insoluble content 0.23%, the main pollutants are pesticides, containing tar substances.

[0051] 2) Take 763g of chemical waste salt and 3.7g of sodium chlorosulfonate and mix them evenly, then put them into a high-temperature melting oxidation furnace, and control the temperature of the system at 900°C. When the system temperature reached 900°C, the timer was started, and the experiments verified the data of staying for 0.5h, 1h, and 3h respectively. After reaching the set dwell time, a sample is taken for analysis.

[0052] Described high-temperature melting and oxidizing furnace takes horizontal flame ...

Embodiment 3

[0057] Example 3 A method for treating waste chemical industry salt by high temperature fusion oxidation

[0058] A method for treating chemical waste salt by high-temperature fusion oxidation method of the present invention comprises the following steps:

[0059] (1) The basic parameters of pesticide waste salt are: TOC content 13067mg / kg, moisture content 6%, water insoluble content 0.23%, the main pollutants are pesticides, containing tar substances.

[0060] 2) Take 693g of chemical waste salt and 4.2g of sodium bicarbonate and mix them evenly, then put them into the high-temperature melting oxidation furnace, and control the temperature of the system at 900°C. When the system temperature reached 900°C, the timer was started, and the experiments verified the data of staying for 0.5h, 1h, and 3h respectively. After reaching the set dwell time, a sample is taken for analysis.

[0061] Described high-temperature melting and oxidizing furnace takes horizontal flame kiln as e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com