Sewage treatment process

A sewage treatment and process technology, applied in biological water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of unsatisfactory degradation effect of ammonia nitrogen impurities, high sewage treatment cost, and eutrophic water body. problems, such as strengthening the economic promotion value, improving the recovery rate, and speeding up the speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in further detail below in conjunction with the accompanying drawings.

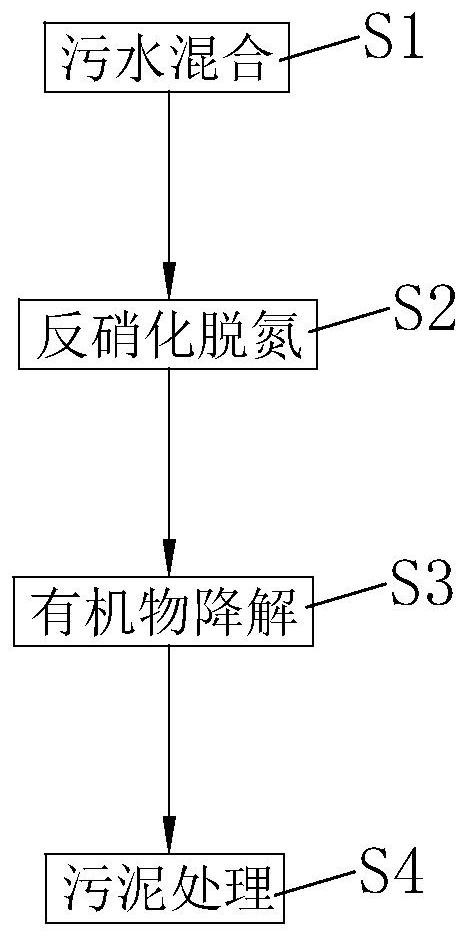

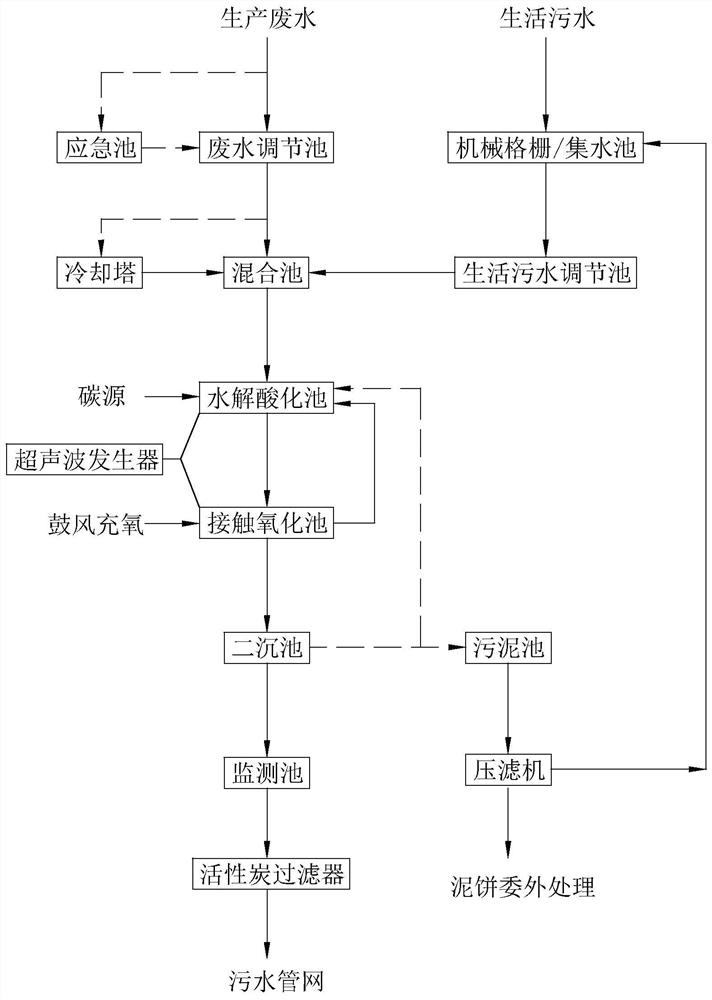

[0036] refer to figure 1 , is a kind of sewage treatment process disclosed by the present invention, comprises the following steps:

[0037] S1, sewage mixing. Firstly, the production wastewater from the workshop is pumped to the wastewater adjustment tank, and the water quality, water volume and pH value are adjusted at different periods before being passed into the mixing tank;

[0038] At the same time, the domestic sewage is filtered through the mechanical grille and flows into the sump by itself, and then pumped to the domestic sewage regulating tank, and is continuously and quantitatively transported to the mixing tank by the pump to mix with the production wastewater;

[0039] S2, denitrification and denitrification, the mixed sewage is passed into the hydrolytic acidification tank, and the hydrolytic acidification tank adopts the biofilm method, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com