Luminous geopolymer mortar for building facades

A technology for building exterior walls and geopolymers, applied in cement production, etc., can solve the problems of luminescent materials not being able to play, luminescent materials emitting light, luminous cement mortar products luminous brightness and luminous afterglow time, etc., to reduce cracking Risk, good luminous effect, guaranteed fluidity and construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

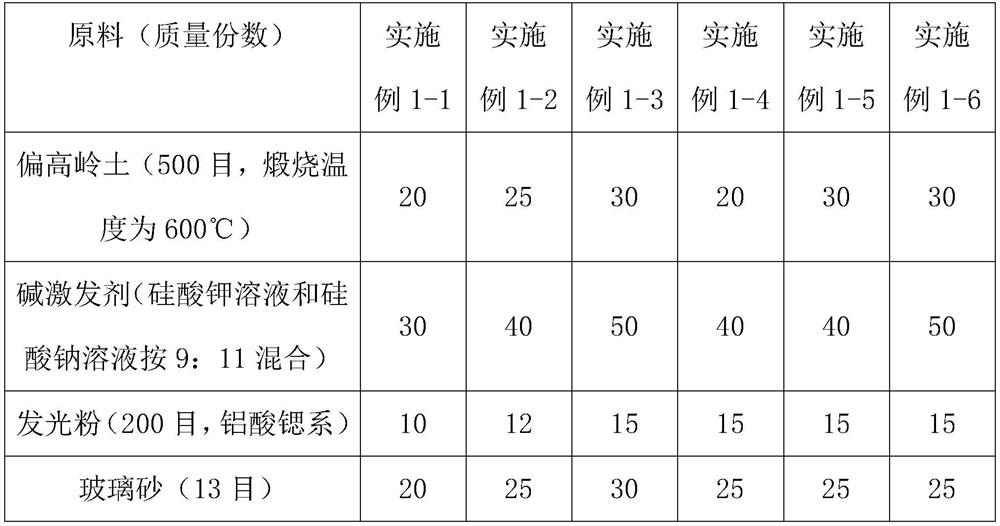

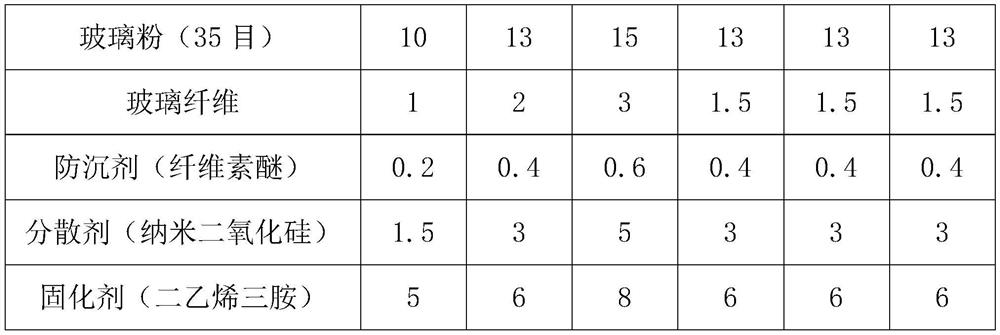

[0067] Comparative example group 1 - a preparation method of luminescent geopolymer mortar

[0068] The mortar raw materials were weighed according to the formula in Table 3 and stirred. During the stirring process, water was slowly added to mix the mortar raw materials and water evenly to obtain a luminous geopolymer mortar.

[0069] Table 3 Raw materials and proportions of different luminescent geopolymer mortars in comparative example group 1

[0070]

[0071]

[0072] Prepare luminous geopolymer mortar according to the above method, and carry out tensile strength test, afterglow time test and luminous intensity test on the obtained luminous geopolymer mortar, the results are shown in the following table:

[0073] Table 4 Performance test results of different luminescent geopolymer mortars in comparative example group 1

[0074] Performance Testing Tensile strength (MPa) Afterglow time(min) Luminous intensity (mcd / m 2 )

Comparative example 1-1...

Embodiment 3

[0097] Example 3 - A preparation method of luminescent geopolymer mortar for building exterior walls

[0098] Weigh 30 parts of 500-mesh metakaolin (calcination temperature is 700°C), 40 parts of alkali activator (mixture of potassium silicate solution and sodium silicate solution at 9:11), 15 parts of 200-mesh luminescent powder (strontium aluminate series) , 25 parts of 13-mesh glass sand, 13 parts of 35-mesh glass powder, 1.5 parts of glass fiber, 0.4 part of anti-sedimentation agent (cellulose ether), 3 parts of dispersant (nano silicon dioxide) and curing agent (diethylenetriamine) 6 parts were stirred, and during the stirring process, water was slowly added to mix the mortar raw materials and water evenly to obtain a luminescent geopolymer mortar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com