Process for synthesizing methyl p-hydroxyphenylpropionate

A technology for methyl hydroxyphenylpropionate and methyl phenylpropionate is applied in the field of synthesizing methyl parahydroxyphenylpropionate, can solve problems such as low reaction yield, waste water generation, environmental pollution, etc., and achieves simple production process and easy operation. Convenience and the effect of less catalyst consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

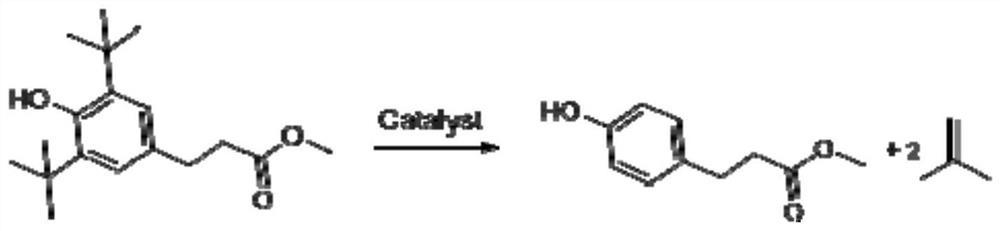

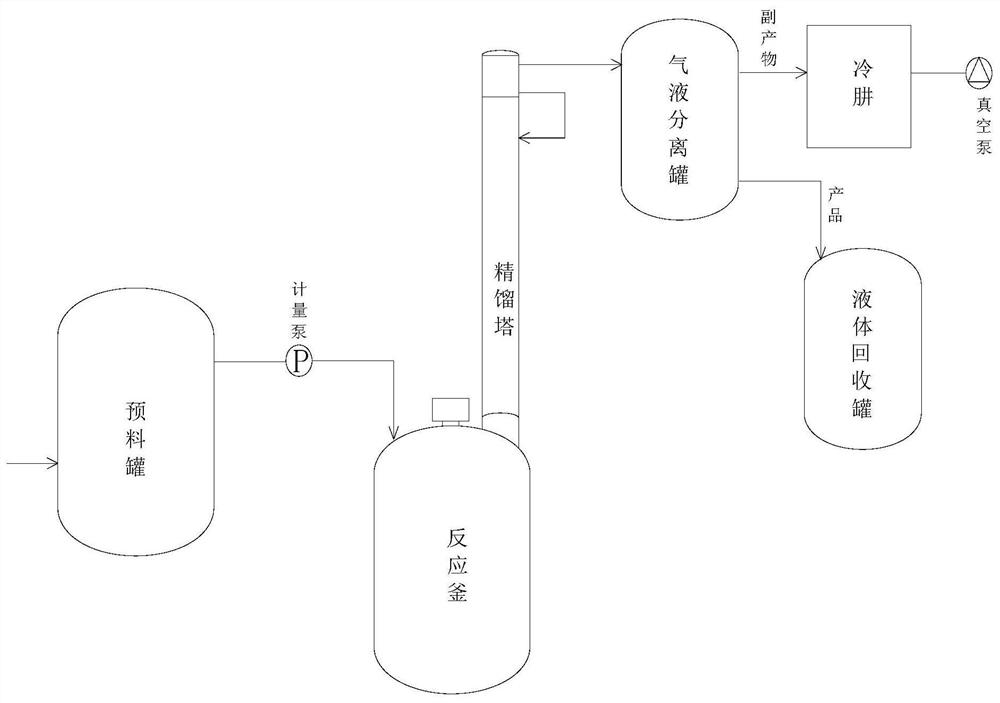

Embodiment 1

[0028] Preparation of methyl p-hydroxyphenylpropionate: 500g of liquid 3-(3,5-di-tert-butyl-4-hydroxy)methyl phenylpropionate at a temperature of 100°C was continuously Add dropwise to the reaction kettle containing 1.0g of phosphotungstic acid catalyst and carry out stirring reaction at a temperature of 115°C (the chemical reaction formula is as follows figure 1 Shown), generate product methyl p-hydroxyphenylpropionate and by-product isobutylene, and the material in the reactor is distilled by rectifying tower, the temperature of rectifying tower tower top is 105 ℃, and the pressure of reactor and rectifying tower is- 1kpa, after the reaction is stable, the material in the reactor is about 100g, the reflux ratio at the top of the rectification tower is controlled to be 1:1, the material in the reactor is continuously extracted through the top of the rectification tower, part of methyl p-hydroxyphenylpropionate and isobutyl Extracted from the top of the rectifying tower, the r...

Embodiment 2

[0031] Preparation of methyl p-hydroxyphenylpropionate: 500g of liquid 3-(3,5-di-tert-butyl-4-hydroxy)methyl phenylpropionate at a temperature of 100°C is continuously Add it dropwise to a reaction kettle containing 1.0g of phosphotungstic acid catalyst and carry out a stirring reaction at a temperature of 125°C to generate the product methyl p-hydroxyphenylpropionate and by-product isobutylene, and the materials in the reaction kettle are distilled through a rectification tower. The temperature at the top of the rectifying tower is 111°C, the pressure of the reactor and the rectifying tower is -1kpa, the weight of the material in the reactor is about 100g after the reaction is stable, and the reflux ratio at the top of the rectifying tower is controlled to be 1.5:1. The materials in the reactor are continuously extracted through the top of the rectification tower; after complete reaction, the reflux ratio of the top of the rectification tower is maintained, and the materials i...

Embodiment 3

[0034] Preparation of methyl p-hydroxyphenylpropionate: 500g of liquid methyl 3-(3,5-di-tert-butyl-4-hydroxy)phenylpropionate at a temperature of 100°C is continuously passed through a flow pump with a flow rate of 6ml / min Add it dropwise into a reaction kettle containing 1.0g of phosphotungstic acid catalyst and carry out a stirring reaction at a temperature of 135°C to generate the product methyl p-hydroxyphenylpropionate and by-product isobutylene, and the materials in the reaction kettle are distilled through a rectification tower. The temperature at the top of the rectification tower is 115°C, the pressure of the reactor and the rectification tower is -1kpa, the weight of the material in the reactor after the reaction is stable is about 100g, and the reflux ratio at the top of the rectification tower is controlled to be 2:1. The materials in the reactor are continuously extracted through the top of the rectification tower; after complete reaction, the reflux ratio of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com