Ashless diesel oil cleaning synergist and preparation method thereof

A synergist, diesel technology, applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of unfavorable physical and chemical properties of diesel and large amount of addition, and achieve the goal of reducing energy consumption, strong power, and improving diesel quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

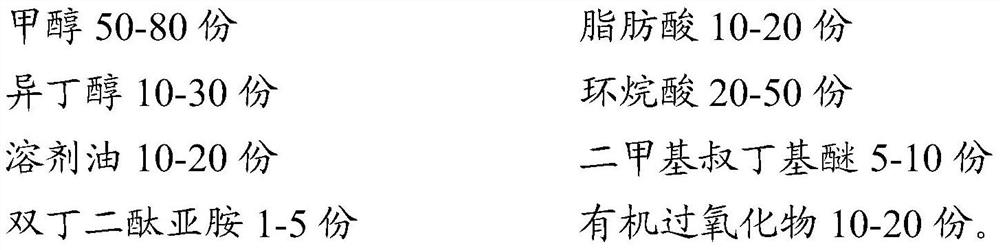

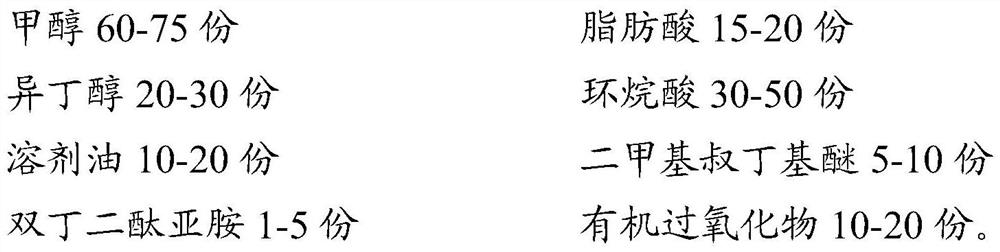

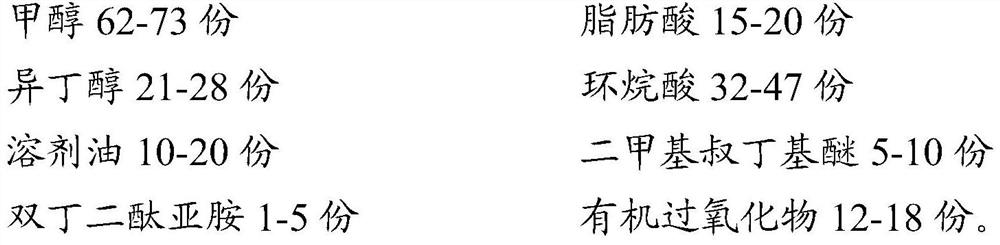

Method used

Image

Examples

Embodiment 1

[0030] A kind of preparation method of ashless diesel oil detergent synergist is as follows:

[0031] First weigh raw materials according to the following proportions: 68 parts by weight of methanol, 17 parts by weight of oleic acid, 25 parts by weight of isobutanol, 40 parts by weight of naphthenic acid, 16 parts by weight of No. 120 solvent naphtha, 9 parts by weight of dimethyl tert-butyl ether Parts by weight, 3 parts by weight of bisbutylimide, 15 parts by weight of peroxycarbonate;

[0032] Then methanol and oleic acid were mixed at room temperature and stirred for 30 minutes;

[0033] Add isobutanol, naphthenic acid and No. 120 solvent oil again, and carry out mixing treatment at room temperature;

[0034] Finally, dimethyl tert-butyl ether, bisbutylimide and peroxycarbonate were added, and mixed thoroughly at room temperature to obtain an ashless diesel detergent synergist. The test results are shown in Table 1.

[0035] Table 1 Technical Requirements and Test Method...

Embodiment 2

[0040] A kind of preparation method of ashless diesel oil detergent synergist is as follows:

[0041] First weigh the raw materials according to the following ratio:

[0042] 70 parts by weight of methanol, 20 parts by weight of palmitic acid, 23 parts by weight of isobutanol, 45 parts by weight of naphthenic acid, 20 parts by weight of No. 180 mineral spirits, 10 parts by weight of dimethyl tert-butyl ether, bisbutylimide 1 part by weight, 13 parts by weight of peroxycarbonate.

[0043] Then methanol and palmitic acid were mixed at room temperature and stirred for 30 minutes;

[0044] Add isobutanol, naphthenic acid and No. 180 solvent oil again, and carry out mixing treatment at room temperature;

[0045] Finally, dimethyl tert-butyl ether, bisbutylimide and peroxycarbonate were added, and mixed thoroughly at room temperature to obtain an ashless diesel detergent synergist. The test results are shown in Table 2.

[0046] Table 2 Technical Requirements and Test Methods of ...

Embodiment 3

[0051] A kind of preparation method of ashless diesel oil detergent synergist is as follows:

[0052] First weigh the raw materials according to the following ratio:

[0053] 66 parts by weight of methanol, 20 parts by weight of linoleic acid, 28 parts by weight of isobutanol, 45 parts by weight of naphthenic acid, 15 parts by weight of No. 190 mineral spirits, 10 parts by weight of dimethyl tert-butyl ether, 5 parts by weight of amine, and 18 parts by weight of peroxycarbonate.

[0054] Then methanol and linoleic acid were mixed at room temperature and stirred for 20 minutes;

[0055] Add isobutanol, naphthenic acid and No. 190 solvent oil again, and carry out mixing treatment at room temperature;

[0056] Finally, dimethyl tert-butyl ether, bisbutylimide and peroxycarbonate were added, and mixed thoroughly at room temperature to obtain an ashless diesel detergent synergist. The test results are shown in Table 3.

[0057] Table 3 Technical Requirements and Test Methods of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com