Denitrification combustion method used for production of cement kiln

A combustion method and cement kiln technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of low energy utilization rate, slow energy release, poor burnout rate of pulverized coal, etc. The effect of low heat consumption and high solid-gas ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

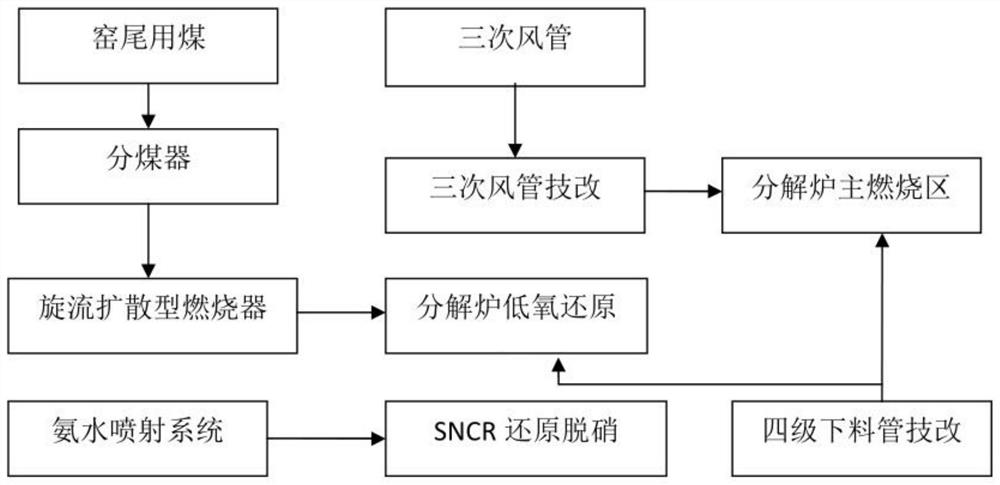

[0011] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0012] combined with figure 1 A denitrification combustion method for cement kiln production, comprising a smoke chamber, a calciner and a tertiary air duct, one end of the smoke chamber is connected to the calciner through a pipe, the other end of the smoke chamber is connected to the cement kiln, the The tertiary air pipe is connected with the calciner, and the top of the smoke chamber is equipped with a coal feeding device and a fourth-stage feeding pipe.

[0013] The coal feeding device is a swirl diffusion burner, and a coal injection nozzle is arranged on the swirl diffusion type burner. The coal injection nozzle is inclined downward and extends into the smoke chamber. The inclination angle of the coal injection nozzle is 5°-20°, and the length of the coal injection nozzle deep into the smoke chamber is 5cm-20cm.

[0014] The working principle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com