Method for preventing and treating blasting raise dust and blasting harmful gas

A technology of harmful gas and ammonia gas, applied in blasting and other directions, can solve the problems of high efficiency and environmental protection, consume a lot of water, and go against environmental protection policies. with the effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

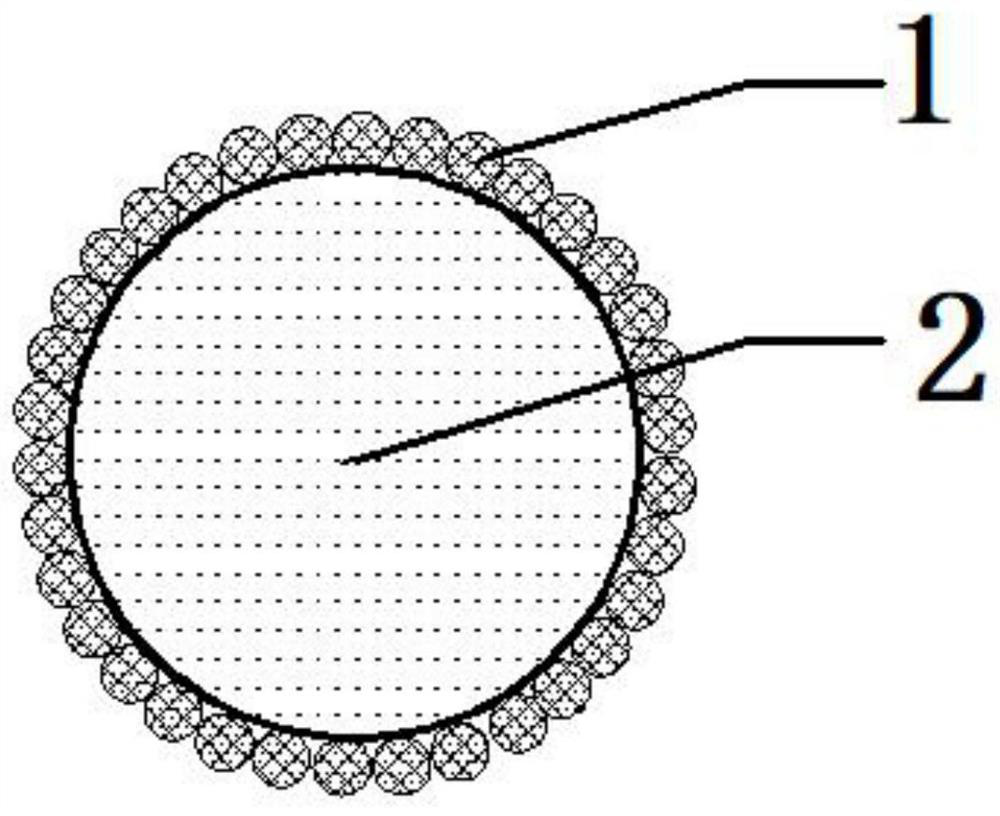

[0020] A method for preventing and controlling blasting dust and harmful gas: the hydrophobic nano-silicon carbide-water type "dry water" material mainly consists of the following components by weight: 5 parts of hydrophobic nano-silicon carbide and 95 parts of water.

[0021] The prevention and control method of the blasting dust and harmful gas produced by blasting, the specific steps are as follows:

[0022] St1: First weigh 95 parts of water, then weigh 5 parts of hydrophobic nano-silicon carbide and add it to the water to mix the two evenly;

[0023] St2: Add the mixture of water and hydrophobic nano-silicon carbide into a high-speed disperser, stir and disperse for 7 minutes at a speed of 4000rpm / min, and then form a "dry water" type material;

[0024] St3: After the charge is completed, the blast hole is blocked with water blasting mud and clay blasting mud, and then a large amount of "dry water" type materials in St2 are laid around the blast hole. Once the blasthole ...

Embodiment 2

[0026] A method for preventing and controlling blasting dust and harmful gas generated by blasting: the hydrophobic nano-silica-copper sulfate type "dry water" material is mainly composed of the following components by weight: 4 parts of hydrophobic nano-silica, mass fraction It is 96 parts of 5% copper sulfate solution.

[0027] The prevention and control method of the blasting dust and harmful gas produced by blasting, the specific steps are as follows:

[0028] St1: first weigh 96 parts of copper sulfate solution with a mass fraction of 5%, then weigh 5 parts of hydrophobic nano-silica and add it to the copper sulfate solution, so that the two are evenly mixed;

[0029] St2: Add the mixture of copper sulfate solution and hydrophobic nano-silica to a high-speed disperser, stir and disperse for 5 minutes at a speed of 6000rpm / min, and then form a "dry water" type material;

[0030] St3: After the charge is completed, the blast hole is blocked with water blasting mud and clay...

Embodiment 3

[0032] A method for preventing and controlling dust and harmful gas produced by blasting: the hydrophobic nano silicon dioxide-water "dry water" material is mainly composed of the following components by weight: 6 parts of hydrophobic nano silicon dioxide and 94 parts of water.

[0033] The prevention and control method of the blasting dust and harmful gas produced by blasting, the specific steps are as follows:

[0034] St1: First weigh 94 parts of water, then weigh 6 parts of hydrophobic nano-silica and add it to water to mix the two evenly;

[0035] St2: Add the mixture of water and hydrophobic nano-silica to a high-speed disperser, stir and disperse for 10 minutes at a speed of 5000rpm / min, and then form a "dry water" type material;

[0036] St3: After the charge is completed, the blast hole is blocked with water blasting mud and clay blasting mud, and then a large amount of "dry water" type materials in St2 are laid around the blast hole. Once the blasthole charge is det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com