Turbulator welding robot system

A technology for welding robots and turbulators, applied in welding equipment, welding equipment, welding accessories, etc., can solve problems such as the inability to realize large-scale automatic welding of turbulators, the inability to use a laser visual positioning device, and the narrow space between blades. To achieve the effect of realizing automatic flow operation, improving welding efficiency and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

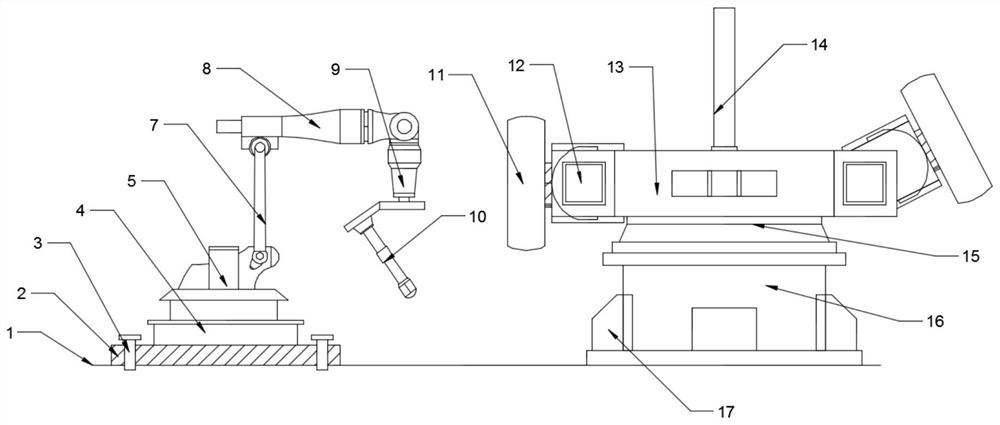

[0025] see figure 1 with figure 2 , in Embodiment 1 of the present invention, a turbulence welding robot system, which includes: a welding assembly and a displacement assembly, and the welding assembly and the displacement assembly are distributed on the left and right sides of the upper end of the ground 1;

[0026] The welding assembly includes a robot base 4, a first motor 5, a mounting frame 6 and a robot arm 7, the first motor 5 is arranged on the upper end of the robot base 4, the output end of the first motor 5 is connected with the mounting frame 6, and the mounting frame 6 upper end A robot arm 7 is movable, and the upper end of the robot arm 7 is provided with an installation terminal 8, and a laser displacement sensor 9 and an argon arc welding torch 10 are installed and fixed on one side of the installation terminal 8, and an anti-collision sensor is provided on the surface of the argon arc welding torch 10;

[0027] The displacement assembly includes a mounting ...

Embodiment 2

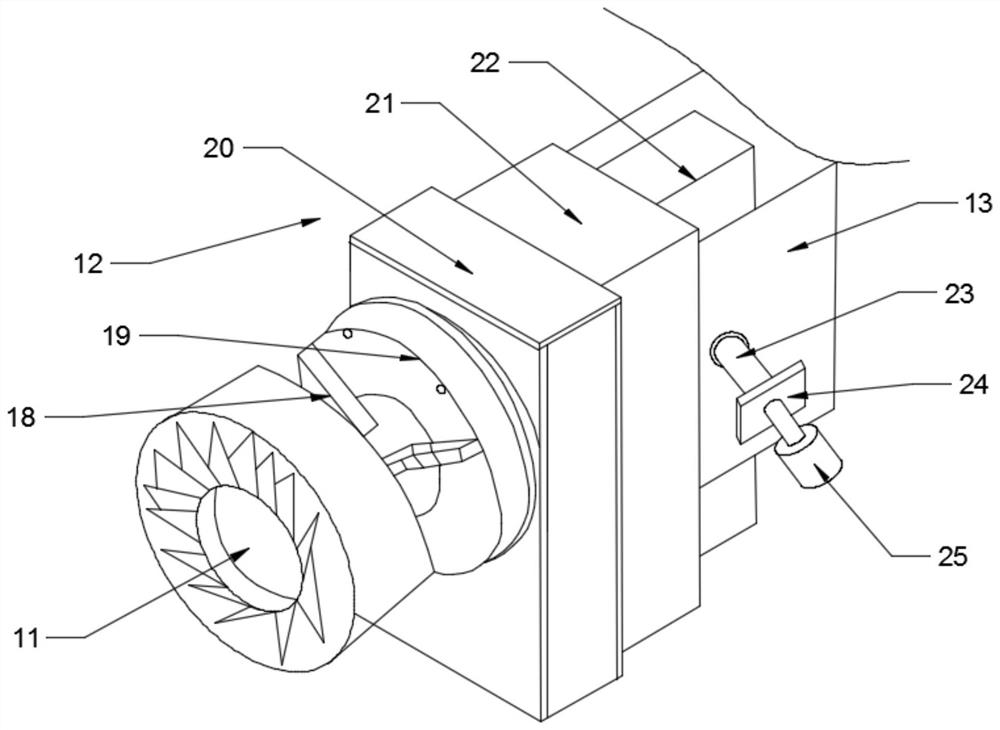

[0031] Further, the number of displacement mechanisms 12 is two, and the two displacement mechanisms 12 are distributed on the left and right sides of the mounting seat 13; through the two displacement mechanisms 12 provided, the two turbulator tooling 11 can be simultaneously adjusted in different states. Operation;

[0032] Specifically, the displacement mechanism 12 includes a clamping seat 19, a cylinder seat 20, an energy supply seat 21 and a rotating plate 22. The surface of the clamping seat 19 is provided with a three-jaw chuck 18, and the three-jaw chuck 18 is arranged on the clamping seat 19. The claw chuck 18 is driven to run by the cylinder block 20, the three-jaw chuck 18 is used to clamp and fix the turbulence tooling 11, one end of the cylinder block 20 is connected to the output shaft of the energy supply seat 21, and the other end of the energy supply seat 21 is installed and fixed with a rotating shaft. plate 22;

[0033] Furthermore, the rotating plate 22 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com