Chemical wastewater treatment method

A technology of chemical wastewater and treatment methods, which is applied in the direction of special compound water treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems that chemical wastewater cannot meet the discharge standards, and achieve the effect of improving treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

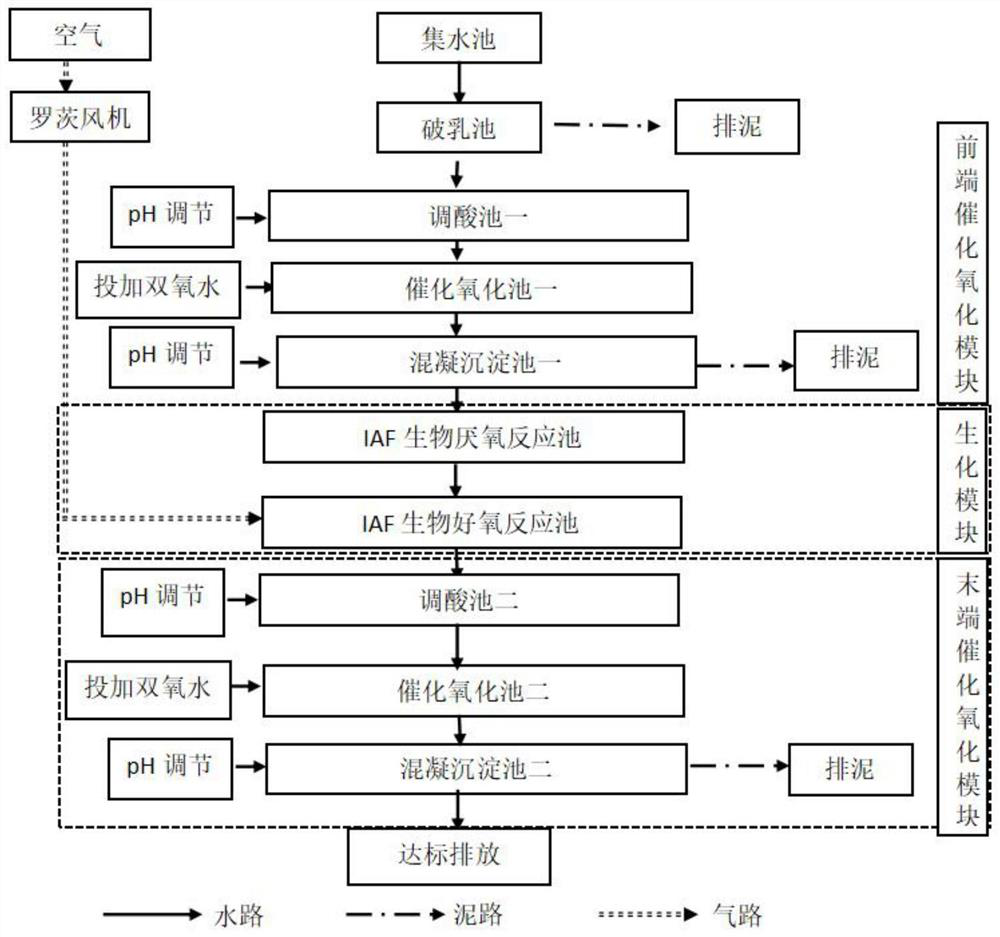

[0041] First, the wastewater collected in the sump is entered into the demulsification tank for demulsification and precipitation, and the sludge obtained after precipitation is discharged to the sludge concentration tank through the mud bucket. The method of dosing is to add flocculants to make the pH of the wastewater greater than 8, and to pretreat the powder suspensions and oily emulsions contained in the wastewater.

[0042] Lift the waste water obtained above from the lifting pump to the acid adjustment pool 1, start the acid, alkali, and hydrogen peroxide metering pumps in the pH online automatic control system in the acid adjustment pool 1, do the dosing, control the pH of the waste water to 3, and start the catalytic oxidation The valve of the aeration pipeline at the bottom of pool one can mix the chemical agent and wastewater evenly, and catalyze and oxidize the Fe in the porous ferroalloy filler in pool one. 2+ as H 2 o 2 Catalyst to generate OH with strong oxida...

Embodiment 2

[0046] This embodiment is the same as the steps of Embodiment 1, the difference is:

[0047] When the acid, alkali and hydrogen peroxide metering pumps in the pH online automatic control system in the acid adjustment pool 1 are turned on, the pH of the wastewater is controlled to be 3.5 and the reaction time is 2.5 hours when dosing. After the Fenton reaction is completed, the pH online automatic control system will The pH of the wastewater is adjusted back to 8. At this time, the COD removal rate of the anaerobic reactor is 70% or VFA<250mg / L. The added nutrients are ammonia water and ammonium dihydrogen phosphate. Adjust the reflux ratio of the sludge to 75%. Set The temperature in the biological aerobic reaction tank is 30°C, and the pH value of the sewage is 7.5, so that the DO concentration in the biological aerobic reaction tank is 4mg / L.

Embodiment 3

[0049] This embodiment is the same as the steps of Embodiment 1, the difference is:

[0050] When the acid, alkali and hydrogen peroxide metering pumps in the pH online automatic control system in the acid adjustment pool 1 are turned on, the pH of the wastewater is controlled to be 4 and the reaction time is 3 hours when dosing. After the Fenton reaction is completed, the pH online automatic control system will The pH of the wastewater was adjusted back to 8.5. At this time, the COD removal rate of the anaerobic reactor was 60% or VFA<300mg / L. The added nutrients were ammonium chloride and trisodium phosphate, and the reflux ratio of the sludge was adjusted to 50%. The temperature in the biological aerobic reaction tank is set to 20°C, the pH value of the sewage is 8.5, and the DO concentration in the biological aerobic reaction tank is 6mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com