Refractory foamed brick and preparation method thereof

A foam brick and refractory technology, applied in the field of architectural ceramics, to achieve the effect of improving the performance of the fire resistance limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a refractory foamed brick. The raw materials include 20 parts of waste brick shavings, 15 parts of potassium albite feldspar, 50 parts of polishing slag, 15 parts of kaolin, 5 parts of bismuth titanate, and 150 parts in parts by mass. 0.5 part of silicon carbide powder, 0.1 part of water reducer A and 0.1 part of water glass.

[0031] The present embodiment provides a kind of preparation method of refractory foam brick, comprises the following steps:

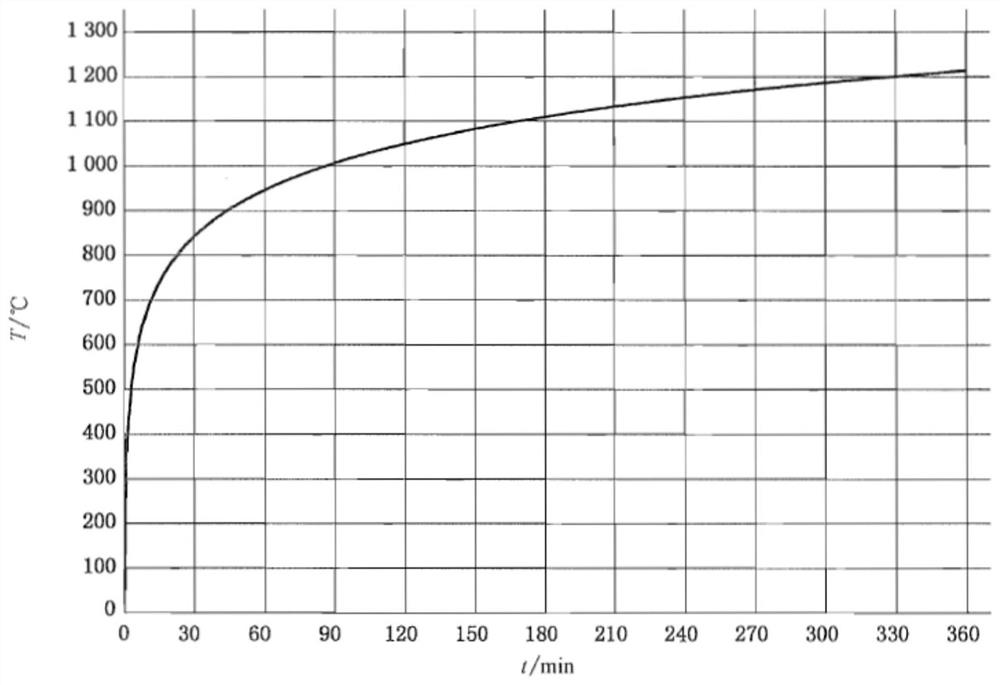

[0032] According to the raw material formula of the refractory foam brick provided in this example, weigh each component, mix all the raw materials and add water to ball mill for 9 hours, according to the quality of raw materials: balls: water = 1:1.5:0.6. Then carry out spray granulation, the particle size is controlled at 40 mesh-80 mesh ≧80%, and the moisture content after drying is <7%. . Set the firing system as normal temperature to 650°C, the heating time is 75min, 650°C for 50min, 650°C ...

Embodiment 2

[0035] This embodiment provides a refractory foamed brick. In terms of parts by mass, its raw materials include 20 parts of waste brick scraps, 15 parts of potassium albite feldspar, 50 parts of polishing slag, 15 parts of kaolin, 3 parts of lead titanate, and 150 parts of 0.7 parts of silicon carbide powder, 0.2 parts of water reducing agent A, 0.2 parts of water glass and 0.1 parts of sodium tripolyphosphate.

[0036] The present embodiment provides a kind of preparation method of refractory foam brick, comprises the following steps:

[0037]According to the raw material formula of refractory foam brick provided in this example, weigh each component, mix all the raw materials and add water ball mill for 8 hours, according to the mass raw material: ball: water = 1:1.5:0.6. Then carry out spray granulation, the particle size is controlled at 40 mesh-80 mesh ≧80%, and the moisture content after drying is <7%. . Set the firing system as normal temperature to 650°C, the heating...

Embodiment 3

[0040] This embodiment provides a refractory foamed brick. In terms of parts by mass, its raw materials include 20 parts of waste brick scraps, 15 parts of potassium albite feldspar, 50 parts of polishing slag, 15 parts of kaolin, 7 parts of lead titanate, and 150 parts of 0.4 parts of silicon carbide powder and 0.3 parts of water reducer A.

[0041] The present embodiment provides a kind of preparation method of refractory foam brick, comprises the following steps:

[0042] According to the raw material formula of the refractory foam brick provided in this example, weigh each component, mix all the raw materials and add water to ball mill for 10 hours, according to the mass of raw materials: ball: water = 1:1.5:0.6. Then carry out spray granulation, the particle size is controlled at 40 mesh-80 mesh ≧80%, and the moisture content after drying is <7%. . Set the firing system as normal temperature to 650°C, the heating time is 100min, 650°C for 60min, 650°C to 950°C, the heat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com