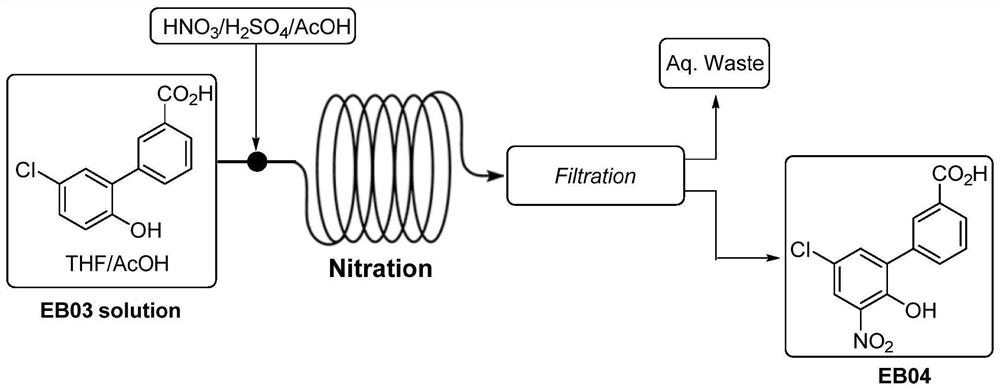

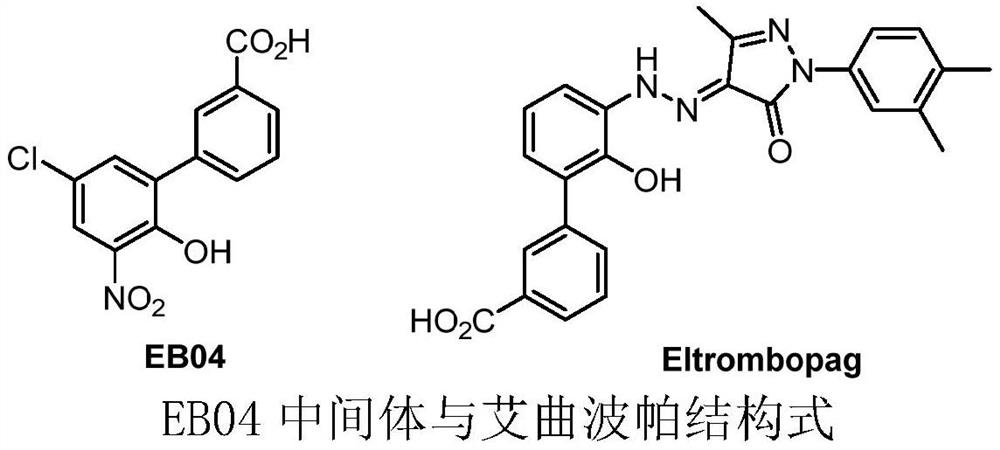

Method for preparing eltrombopag nitration intermediate in micro-channel continuous flow reactor

A technology of microchannel reactors and intermediates, applied in chemical instruments and methods, chemical/physical/physical chemical reactors, nitro compound preparation, etc., can solve problems such as high safety risks and achieve the effect of novel processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Prepare reaction material A: mix starting material EB03 (0.5kg), acetic acid (2.2kg) and tetrahydrofuran (2.25kg), stir and dissolve, let stand, filter out insoluble matter, and filtrate is packed into glass container A, here The mass fraction of EB03 in the mixed liquor was 10.2%.

[0021] (2) Preparation of reaction material B: Add acetic acid (142g) into the reaction flask, cool down to 0-5°C, start stirring, add nitric acid (138g) with a mass fraction of 69%, and then slowly add it dropwise under temperature control conditions Concentrated sulfuric acid (52g), the mixed acid prepared is packed into glass container B, and the massfraction of nitric acid is 28.6% in this mixed solution.

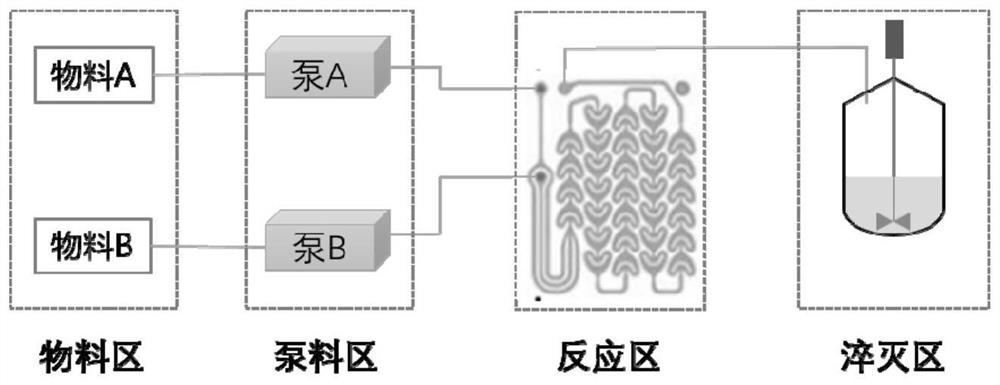

[0022] (3) Turn on the external heat exchanger to control the temperature of the microchannel reactor to 30° C. (a continuous flow microchannel reactor with a Corning heart-shaped structure is used).

[0023] (4) Turn on the constant flow pump A, and deliver material A to the mi...

Embodiment 2

[0028] (1) Preparation of reaction material A: Mix the starting material EB03 (0.60kg), acetic acid (2.61kg) and tetrahydrofuran (2.64kg), stir to dissolve, let stand, filter out insoluble matter, and put the filtrate into glass container A, EB03 The mass fraction is 16%.

[0029] (2) Preparation of reaction material B: Add acetic acid (142g) into the reaction flask, cool down to 0-5°C, start stirring, add 65% nitric acid (138g), and then slowly add concentrated sulfuric acid (52g) dropwise under temperature control. ), the mixed acid prepared is packed into glass container B, and the mass fraction of nitric acid is 28.6%.

[0030] (3) Turn on the external heat exchanger to control the temperature of the microchannel reactor to 50°C.

[0031] (4) Turn on the constant flow pump A to deliver material A to the microchannel at a flow rate of 70mL / min; simultaneously turn on pump constant flow B to deliver material B to the microchannel at a flow rate of 16.4mL / min.

[0032] (5) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com