A lignin-based superhydrophobic coating and preparation method thereof

A super-hydrophobic coating, lignin-based technology, applied in the field of lignin-based super-hydrophobic coating and its preparation, to achieve good use value and application prospects, excellent super-hydrophobic performance, and low cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

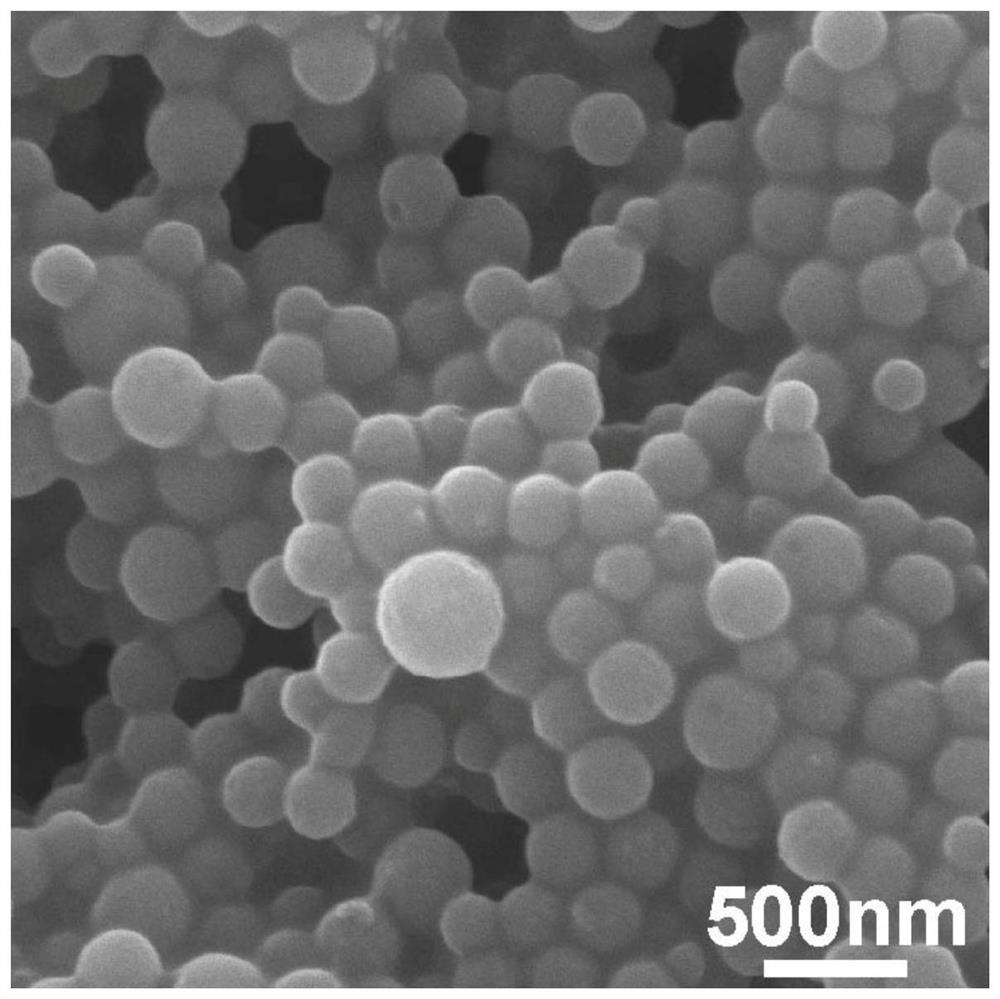

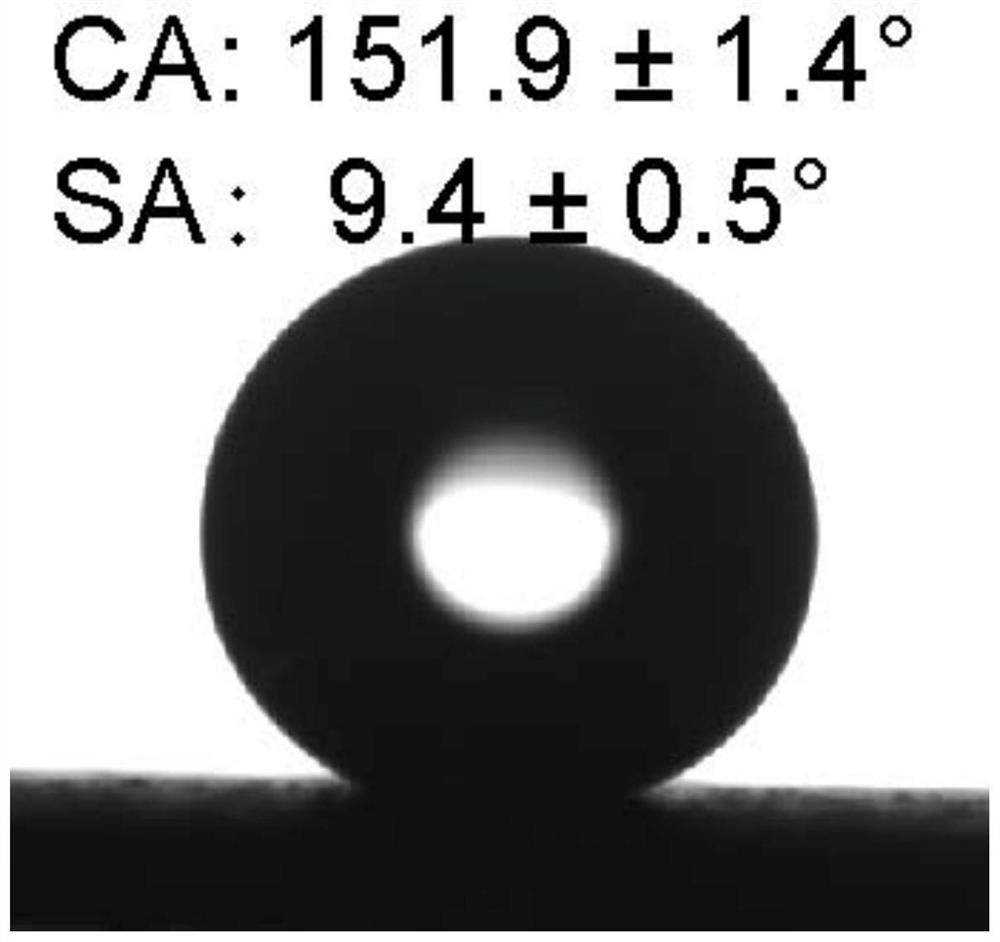

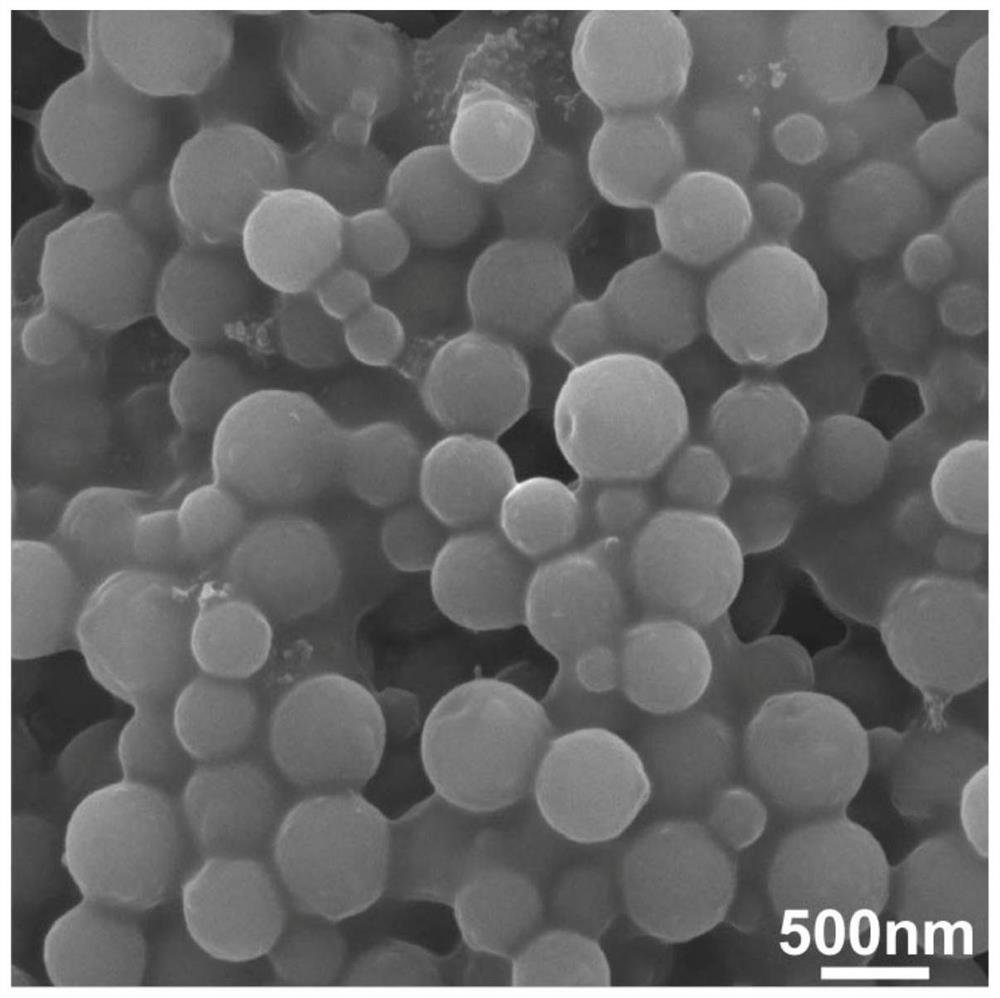

Image

Examples

Embodiment 1

[0042] A lignin-based superhydrophobic coating, comprising the following raw material components in parts by mass:

[0043]

[0044] In this embodiment, the epoxy resin and curing agent are Shenliling SK-103 epoxy super glue produced by Hunan Shenliling Adhesive Manufacturing Co., Ltd., wherein the Shenliling SK-103 epoxy super glue is composed of components A and B Component composition, corresponding to epoxy resin and curing agent respectively.

[0045] In the present invention, epoxy resins capable of fixing low surface energy lignin micro-nanospheres on the base material can be used for the preparation of the superhydrophobic coating of the present invention, such as glycidyl ether epoxy resin, glycidyl ester ring Any one of oxygen resin, glycidylamine epoxy resin, linear aliphatic epoxy resin, and alicyclic epoxy resin can be used as the epoxy resin for preparing the superhydrophobic coating in the present invention, It is not limited to the Shenli Ling SK-103 epoxy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com