Waterproof air-isolating paper cone and preparation method and application thereof

A waterproof partition and paper cone technology, which is applied in special paper, paper, papermaking, etc., can solve the problems of increased paper cone weight and lower speaker sensitivity, and achieves the effects of increased strength, excellent mildew resistance, and excellent film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

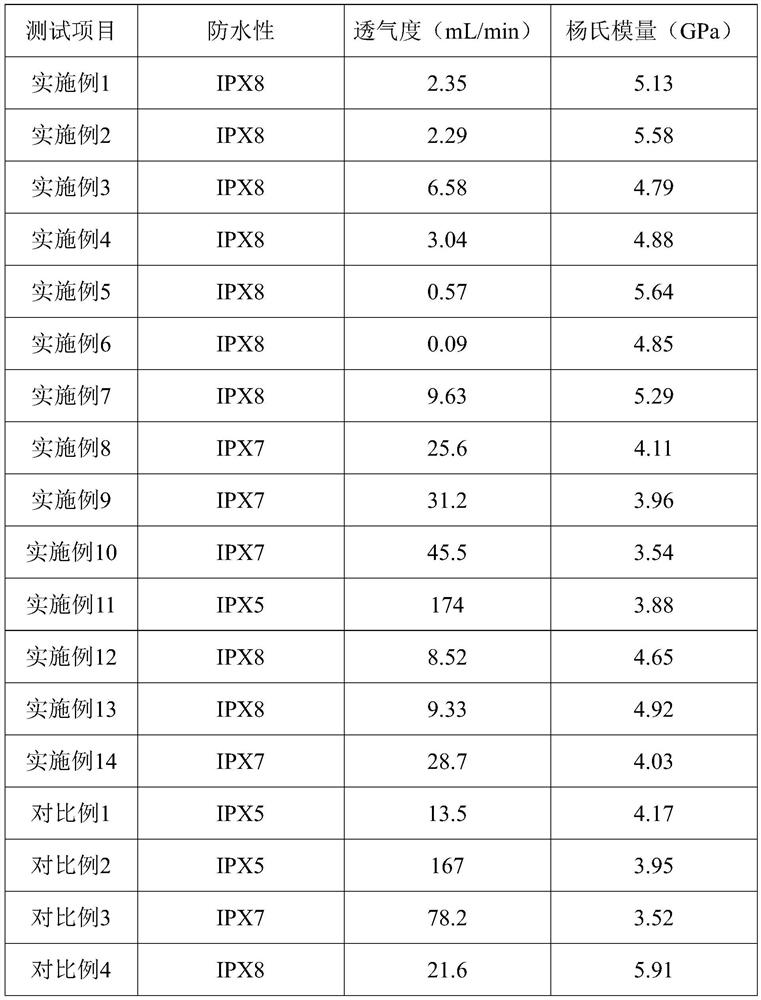

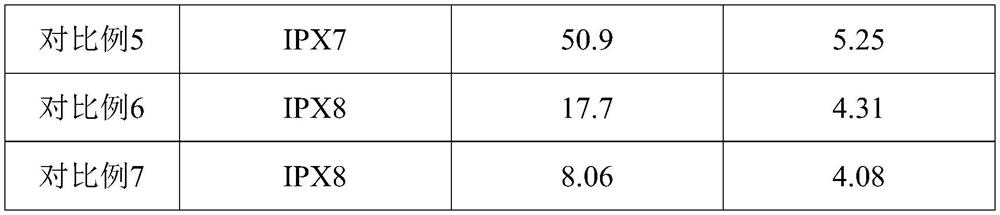

Examples

Embodiment 1

[0074] This embodiment provides a waterproof and air-insulating paper cone, which is prepared by the following preparation method:

[0075] (1) 50 parts of bleached sulphate softwood pulp, 30 parts of cotton pulp and 20 parts of Spanish straw pulp are mixed and beaten to obtain a degree of beating that is 25 ° SR component A; 1 part of chitosan and 100 parts Parts of 0.2mol / L acetic acid solution were mixed to obtain component B;

[0076] (2) Dilute the component A obtained in step (1) with water to obtain a fiber suspension, mix and stir with component B for 20 minutes, then mix and stir with 8 parts of cationic styrene-acrylic emulsion for 15 minutes, and obtain a paper cone wet embryo after filtering;

[0077] (3) placing the wet paper cone blank obtained in step (2) in a high-temperature mold, pressing and drying at 130°C to obtain a paper cone blank;

[0078] (4) Using a punching die to remove the middle hole and edge material of the paper cone blank obtained in step (3)...

Embodiment 2

[0080] This embodiment provides a waterproof and air-insulating paper cone, which is prepared by the following preparation method:

[0081] (1) 40 parts of bleached sulphate softwood pulp, 50 parts of cotton pulp and 10 parts of Spanish straw pulp are mixed and beaten to obtain the component A of 25 ° SR; 1.2 parts of chitosan and 120 parts Parts of 0.2mol / L acetic acid solution were mixed to obtain component B;

[0082] (2) Dilute component A obtained in step (1) with water to obtain a fiber suspension, mix and stir with component B for 20 minutes, then mix and stir with 5 parts of cationic styrene-acrylic emulsion for 15 minutes, and obtain a paper cone wet embryo after filtering;

[0083] (3) placing the wet paper cone blank obtained in step (2) in a high-temperature mold, pressing and drying at 130°C to obtain a paper cone blank;

[0084] (4) Using a punching die to remove the middle hole and edge material of the paper cone blank obtained in step (3), to obtain the waterp...

Embodiment 3

[0086] This embodiment provides a waterproof and air-insulating paper cone, which is prepared by the following preparation method:

[0087] (1 ') 60 parts of bleached kraft softwood pulp, 20 parts of cotton pulp and 20 parts of Spanish grass pulp are mixed and beaten to obtain a degree of percussion as component A of 25 ° SR; 0.4 parts of chitosan and 20 parts of 0.2mol / L acetic acid solutions were mixed to obtain component B;

[0088] (2') Dilute the component A obtained in step (1') with water to obtain a fiber suspension, mix and stir with 10 parts of cationic styrene-acrylic emulsion for 15 minutes, and filter to obtain a paper cone wet embryo;

[0089](3') Place the wet paper cone embryo obtained in step (2') in a high-temperature mould, and after pressing and drying at 130°C, use the component B obtained in step (1') to carry out surface spraying treatment. Dry at 50°C for 1 hour to obtain a paper cone blank;

[0090] (4') Using a punching die to remove the middle hole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Fiber length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com