Aquatic feed containing clostridium autoethanogenum protein and production process of aquatic feed

A technology of Clostridium ethanolicum and aquatic feed, which is applied in the field of freshwater fish breeding, can solve the problems of poor product quality, amino acid digestibility, amino acid imbalance, etc., and achieves the effects of good economic benefits, completeness, good balance, and high protein content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The production of embodiment 1 ethanol clostridium protein

[0028] A kind of clostridium ethanol protein production process, comprises the following steps:

[0029] (1) Cultivate Clostridium autoethanogenum in the culture medium, and select mature Clostridium autoethanogenum as the fermentation strain; the Clostridium autoethanogenum has a preservation number of DSM10061 and a preservation address of the German Culture Collection, DSMZ.

[0030] (2) Pour the ethanol fermentation raw material into the fermenter, the ethanol fermentation raw material is in a liquid state, add the fermentation strain into the fermenter and mix with the ethanol fermentation raw material.

[0031] (3) Pass CO gas into the fermenter, CO gas discharges the air in the fermenter and fills the space in the fermenter, and then seals the exhaust port of the fermenter; a gas detection device is provided at the vent port of the fermenter If the gas discharged from the outlet is CO, seal the outlet ...

Embodiment 2

[0035] Preparation and fish feeding of embodiment 2 fish feed

[0036] The preparation method of the fish feed is as follows: uniformly mix the ethanol clostridial protein, other raw materials and water to obtain a mixed material, make the mixed material into granules, and dry the fish feed to obtain the fish feed.

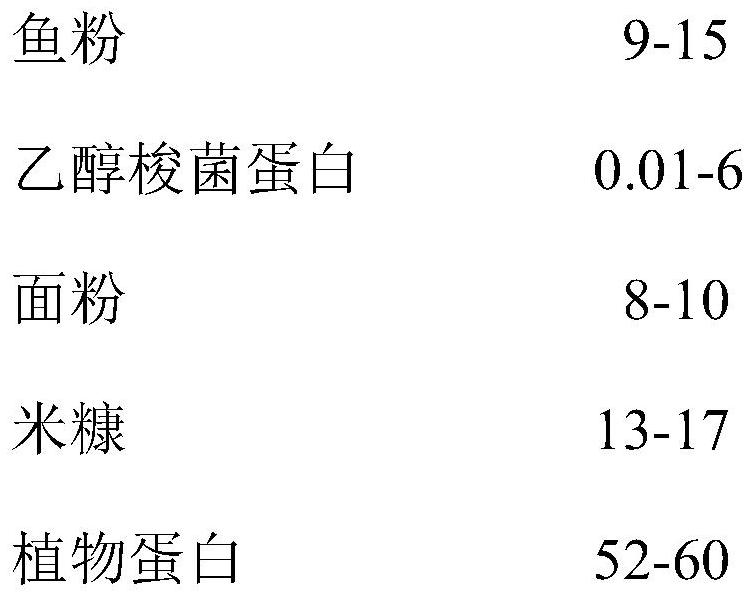

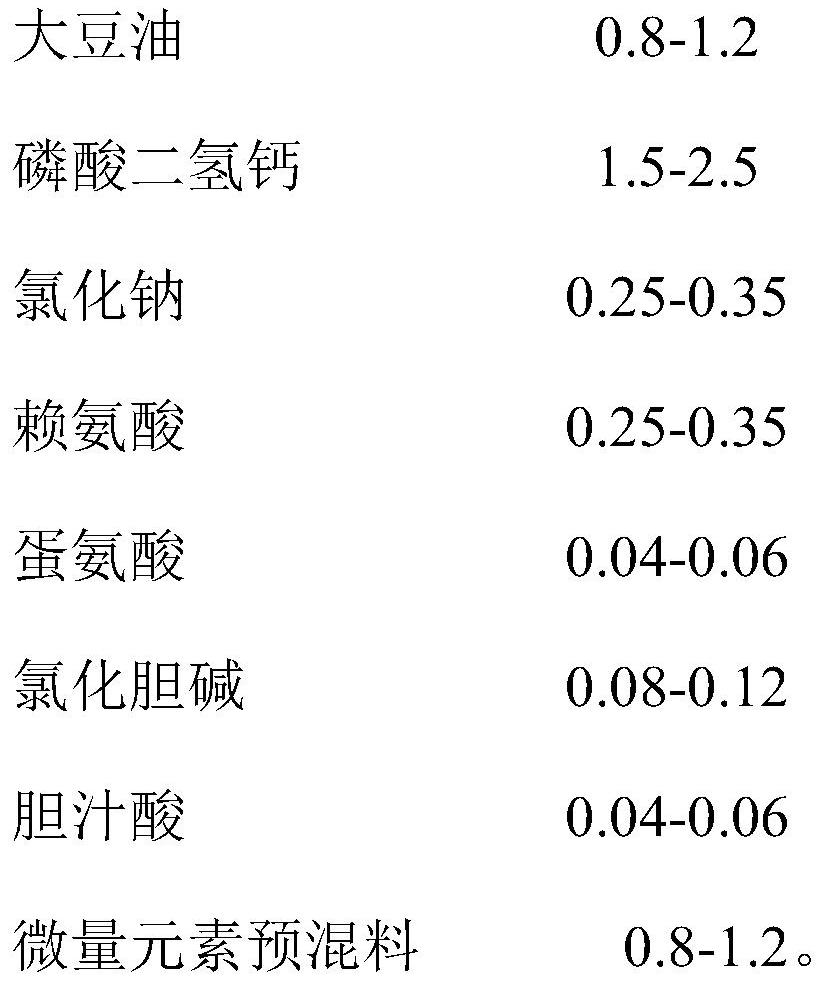

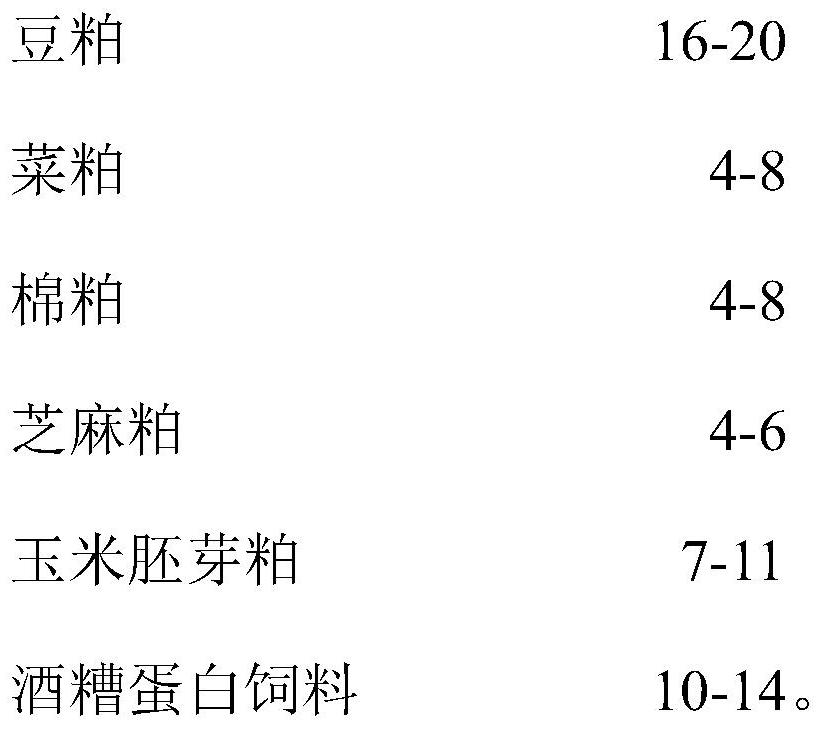

[0037] A total of 540 carps with an initial body weight of (25.67±0.03) g were selected and randomly divided into 6 groups with 3 replicates in each group and 30 fish in each replicate. The control group (J0 group) was fed with basic feed, and the test group was fed with 3% (J3 group), 6% (J6 group), 9% (J9 group), 12% (J12 group), and 15% (J15 group) respectively. Clostridium ethanol protein was used to replace the fish meal in the basal feed in equal amounts, and the breeding cycle was 90 days. The specific formula is shown in Table 1, the growth of fish is shown in Table 2, and the biochemical indicators of fish plasma are shown in Table 3.

[0038] Table 1 F...

Embodiment 3

[0050] Embodiment 3 enlarges and replaces experiment

[0051] In order to further verify the effect of the replacement of Clostridium ethanol protein and fish meal on the growth performance and serum biochemical indicators of fish, more experiments were carried out.

[0052] The preparation method of fish feed is identical with embodiment 2

[0053] A total of 900 carps with an initial body weight of (25.67±0.03) g were selected and randomly divided into 10 groups, with 3 replicates in each group and 30 fish in each replicate. Respectively with 1% (T1 group), 2% (T2 group), 3% (T3 group), 4% (T4 group), 5% (T5 group), 6% (T6 group) of Clostridium ethanol in equal amounts Replace the fish meal in the basal feed, and the breeding cycle is 90 days; at the same time, in order to study whether the Clostridium ethanol protein replaces the fish meal, whether it has synergistic / antagonistic effect with other raw materials, increase 4 groups to use 3% (T3-1 group), 3% ( T3-2 group), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com