Composite reverse osmosis membrane and preparation method thereof

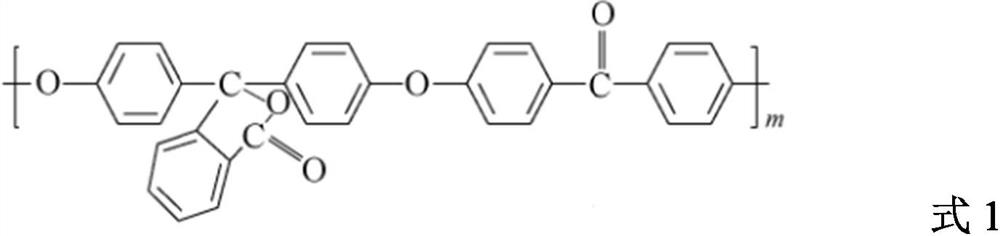

A technology of reverse osmosis membrane and base membrane, which is applied in the field of composite reverse osmosis membrane and its preparation, and can solve the problems of further improvement of high temperature resistance, complicated reverse osmosis membrane components and manufacturing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

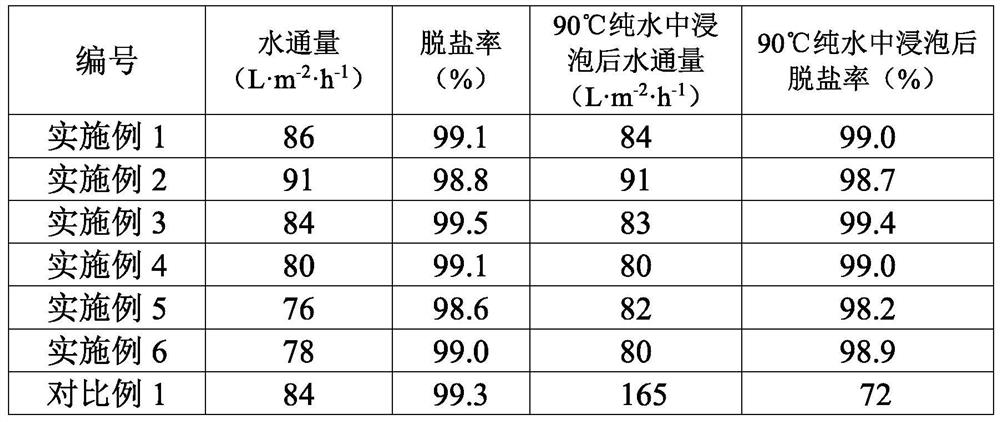

Examples

preparation example Construction

[0026] According to the second aspect of the present invention, the present invention provides a kind of preparation method of composite reverse osmosis membrane, and this preparation method comprises the following steps:

[0027] (1) Preparation of casting solution

[0028] mixing polyaryletherketone containing phenolphthalein side groups, a porogen, and a solvent, dissolving the polyaryletherketone containing phenolphthalein sidegroups in the solvent, filtering and defoaming in sequence to obtain a casting solution;

[0029] (2) Dry-wet preparation of supporting basement membrane

[0030] The casting solution is coated on the polyester non-woven fabric as the support layer, after evaporation, it is immersed in a water bath (for example, a deionized water bath) or an ethanol bath to pre-cure to form a film, and then further solidified, so that the support layer A basement membrane layer is formed on the basement membrane to obtain a supporting basement membrane;

[0031] (3...

Embodiment 1

[0066] This example is used to illustrate the composite reverse osmosis membrane of the present invention and its preparation method.

[0067] (1) Preparation of casting solution

[0068] Mix PEK-C, PVP-K30 and DMAc in a mass ratio of 10:1:89, stir at 60°C for 20 hours to completely dissolve PEK-C in the solvent to obtain a uniform mixture, filter the mixture to remove insoluble Impurities are finally left to stand for 30 hours to degas to obtain the casting solution.

[0069] (2) Dry-wet preparation of supporting basement membrane

[0070] Apply the casting solution prepared in step (1) to the polyester non-woven fabric with a film scraper, evaporate at room temperature for 10 seconds, immerse in a 30°C deionized water bath for 10 minutes to pre-cure to form a film, and then soak in a 30°C deionized water for 48 hours to form a basement membrane layer on the support layer to obtain a support basement membrane.

[0071] (3) Generate functional layer

[0072] Dissolving m-p...

Embodiment 2

[0078] This example is used to illustrate the composite reverse osmosis membrane of the present invention and its preparation method.

[0079] (1) Preparation of casting solution

[0080] Mix PEK-C, PEG-400 and DMF in a mass ratio of 15:3:82, stir at 70°C for 15 hours to completely dissolve PEK-C in the solvent to obtain a uniform mixture, filter the mixture to remove insoluble Impurities, and finally put it under vacuum for 2h to defoam to obtain the casting solution.

[0081] (2) Dry-wet preparation of supporting basement membrane

[0082] Apply the casting solution prepared in step (1) onto the polyester non-woven fabric with a film scraper, evaporate at room temperature for 1 min, immerse in a 60°C deionized water bath for 5 min to pre-cure to form a film, and then soak in a 25°C deionized water for 72 hours to form a basement membrane layer on the support layer to obtain a support basement membrane.

[0083] (3) Generate functional layer

[0084] Dissolving m-phenylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com