Fireproof antibacterial special functional plate and preparation method thereof

A functional and board technology, applied in the field of fireproof and antibacterial special functional board and its preparation, can solve the problems of no waterproof, no antibacterial, no mildew proof and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

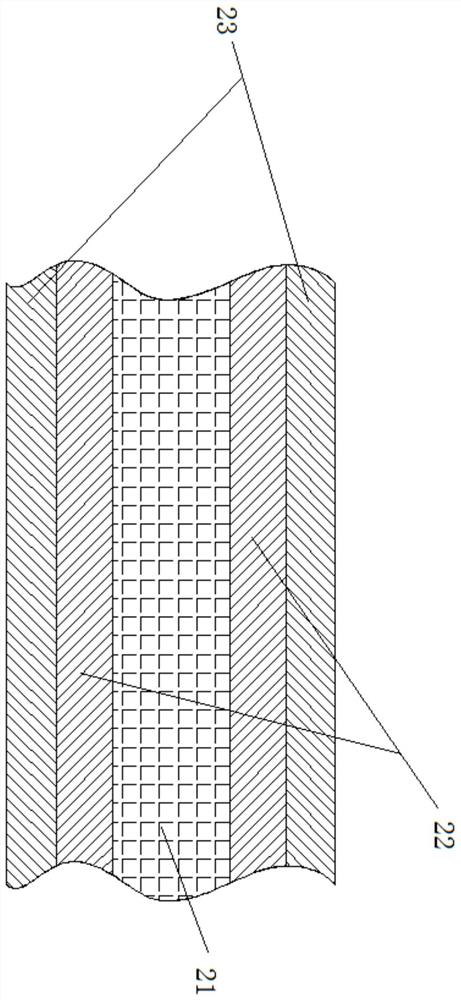

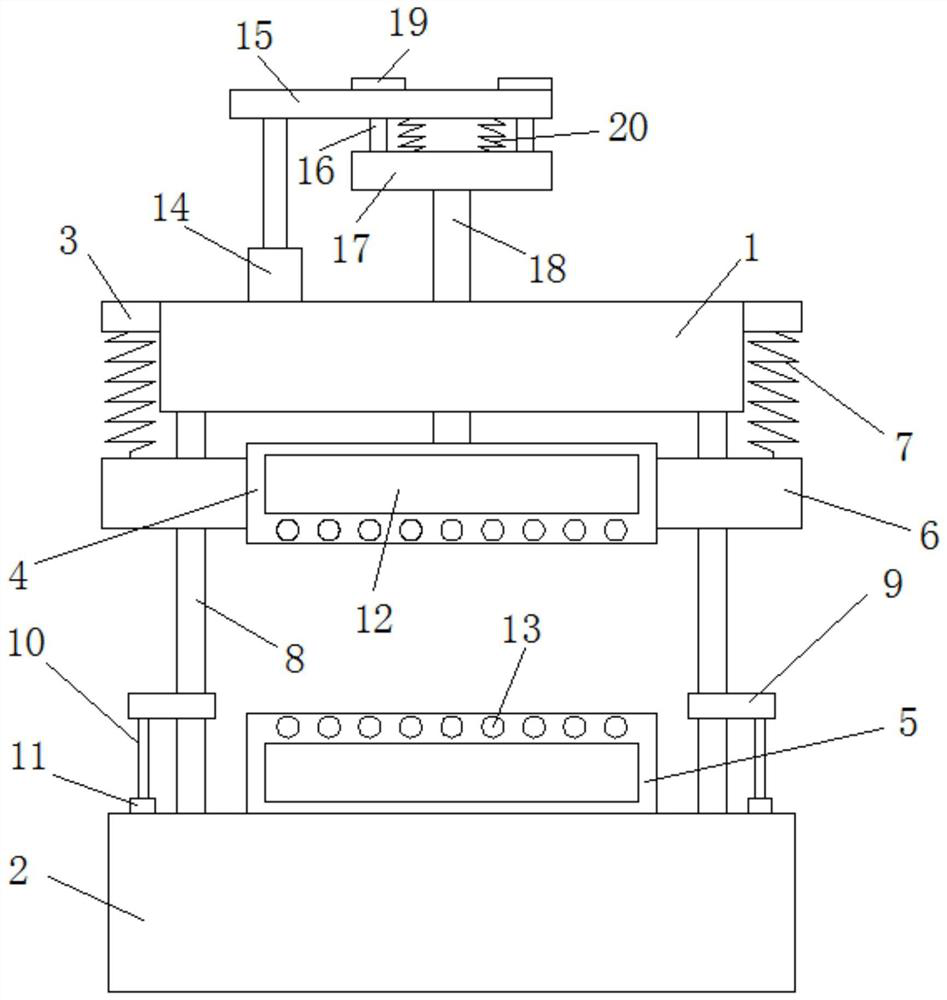

[0029] The present invention also provides a method for preparing a fireproof and antibacterial special functional plate, which is characterized in that the specific steps are as follows:

[0030] S1: Preparation of glass fiber mat: a glass fiber mat obtained by bonding chopped fibers and a binder and then drying;

[0031] S2: Prepare the glass fiber mat resin layer: immerse the glass fiber mat prepared in step S1 in the resin slurry to form a glass fiber mat resin layer, and the immersion time is 2s-500s;

[0032] S3: Thermocompression molding: transport the glass fiber thin felt resin layer prepared in step S2 to the hot pressing station of the hot press, and then place the filler layer and the decorative film layer on the glass fiber thin felt resin layer in turn, and then Start the hot press for hot-press compounding, wherein the molding temperature is 80°C-200°C, the molding time is 5min-90min, and the molding pressure is 5MPa-30MPa.

[0033] Above-mentioned step S1: the...

Embodiment 1

[0044] In Example 1, the glass fiber mat is impregnated with phenolic resin slurry, and the resin slurry content is 50%. After impregnating the resin, it is transferred to a hot press machine for hot pressing and compounding. The molding temperature is 140°C, the molding time is 15min, and the molding pressure is 20MPa. After molding, the surface is covered with a decorative film to obtain a fireproof and antibacterial special functional board.

[0045] The combustion grade of the product reaches Grade A;

[0046] Wear resistance: 5000 rpm;

[0047] Mildew resistance: level 0;

[0048] Antibacterial properties: Anti-Staphylococcus aureus, Escherichia coli;

[0049] Formaldehyde emission level E1;

[0050] Pollution resistance: After 24 hours of contact with the following substances, wipe with neutral detergent or alcohol and observe the surface conditions: vinegar, coffee, soy sauce, tomato sauce, lemon juice, wine, cola, black tea, yogurt, tin water (1% ), soda, formalin,...

Embodiment 2

[0054] In Example 2, the resin slurry content in the glass fiber felt impregnated with epoxy resin slurry is 60%, and the blank after impregnation with resin and the surface decorative film are transferred to a hot press machine for hot pressing and compounding, wherein the molding temperature is 130°C, and the molding time is 15min, forming pressure 15MPa, to obtain fireproof and antibacterial special functional board.

[0055] The combustion grade of the product reaches Grade A;

[0056] Wear resistance: 5000 rpm;

[0057] Mildew resistance: level 0;

[0058] Antibacterial properties: Anti-Staphylococcus aureus, Escherichia coli;

[0059] Formaldehyde emission level E1;

[0060] Pollution resistance: After 24 hours of contact with the following substances, wipe with neutral detergent or alcohol and observe the surface conditions: vinegar, coffee, soy sauce, tomato sauce, lemon juice, wine, cola, black tea, yogurt, tin water (1% ), soda, formalin, milk, alcohol (50%), hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com