Preparation process of high-water-absorption transfer type tipping paper

A preparation process and high water absorption technology, applied in paper, papermaking, paper coating, etc., can solve the problems of increased time and cost, reduced production efficiency, cumbersome preparation process, etc., to increase production efficiency, improve work efficiency, and facilitate operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: The present invention relates to the preparation technology of superabsorbent transfer type tipping paper, comprises the following steps:

[0023] (1) Preparation of super absorbent transfer base paper; (2) Printing; (3) Hot stamping; (4) Slitting; (5) Perforating; (6) Packaging.

[0024] The step (1) is specifically:

[0025] (1-1) Weigh the following components by weight, 60 parts of plant fiber, 10 parts of calcium carbonate, 10 parts of water, 10 parts of starch, 1 part of benzisothiazolyl-3(2H)-one, polyethylene 3 parts of imine, 1 part of alkyl ketene dimer, 3 parts of polyurethane resin, 3 parts of acrylate copolymer, 20 parts of ethanol, 1 part of propylene glycol methyl ether, and 1 part of styrene-butadiene copolymer.

[0026] (1-2), mix the components in step (1-1) and beat to form slurry, add sizing solution during the beating process, and form the bottom paper layer after mixing the slurry and sizing solution, wherein, sizing The amount of l...

Embodiment 2

[0036] Embodiment 2: the preparation technology of superabsorbent transfer type tipping paper, comprises the following steps:

[0037] (1) Preparation of super absorbent transfer base paper; (2) Printing; (3) Hot stamping; (4) Slitting; (5) Perforating; (6) Packaging.

[0038] The step (1) is specifically:

[0039] (1-1) Weigh the following components by weight, 70 parts of plant fiber, 15 parts of calcium carbonate, 15 parts of water, 20 parts of starch, 1.5 parts of benzisothiazolyl-3(2H)-one, polyethylene 4 parts of imine, 3 parts of alkyl ketene dimer, 4 parts of polyurethane resin, 4 parts of acrylate copolymer, 30 parts of ethanol, 1.5 parts of propylene glycol methyl ether, and 1.5 parts of styrene-butadiene copolymer.

[0040] (1-2), mix the components in step (1-1) and beat to form slurry, add sizing solution during the beating process, and form the bottom paper layer after mixing the slurry and sizing solution, wherein, sizing The amount of liquid added to the slur...

Embodiment 3

[0050] Embodiment 3: the preparation technology of superabsorbent transfer type tipping paper, comprises the following steps:

[0051] (1) Preparation of super absorbent transfer base paper; (2) Printing; (3) Hot stamping; (4) Slitting; (5) Perforating; (6) Packaging.

[0052] The step (1) is specifically:

[0053] (1-1) Weigh the following components by weight, 80 parts of plant fiber, 20 parts of calcium carbonate, 20 parts of water, 30 parts of starch, 2 parts of benzisothiazolyl-3(2H)-one, polyethylene 5 parts of imine, 5 parts of alkyl ketene dimer, 5 parts of polyurethane resin, 5 parts of acrylate copolymer, 40 parts of ethanol, 2 parts of propylene glycol methyl ether, 2 parts of styrene-butadiene copolymer.

[0054] (1-2), mix the components in step (1-1) and beat to form slurry, add sizing solution during the beating process, and form the bottom paper layer after mixing the slurry and sizing solution, wherein, sizing The amount of liquid added to the slurry is 6% b...

PUM

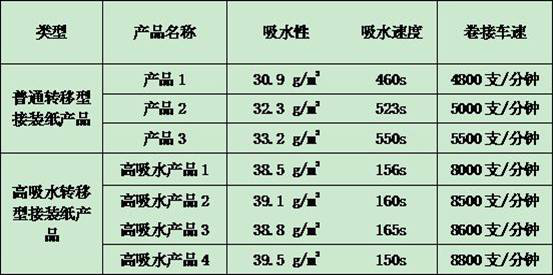

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com